Two-dimensional test model and method for simulating tunnel excavation stratum loss

A technology for stratum loss and tunnel excavation, which is applied in the field of underground engineering simulation test model and two-dimensional test model for simulating tunnel excavation stratum loss, can solve the problems of high cost and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

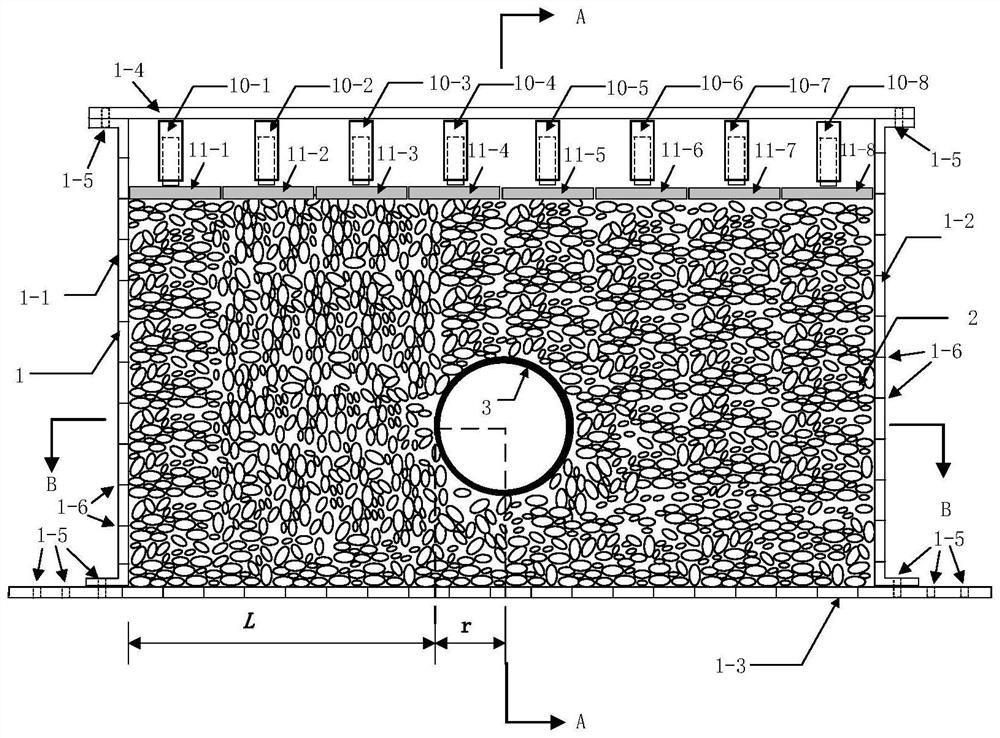

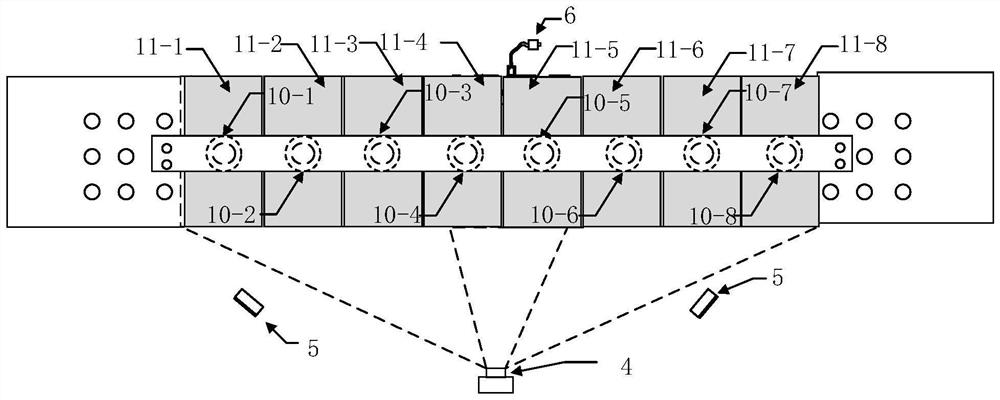

[0048] This embodiment provides a two-dimensional test model for simulating formation loss in tunnel excavation, as shown in the attached Figure 2-5 As shown, including model box and soil layer system, formation loss simulation system, loading system and monitoring system; among them,

[0049] The model box and soil layer system includes a U-shaped movable steel frame 1, and similar soil 2 filled in the U-shaped movable steel frame 1, and the similar soil 2 wraps the air bag 3;

[0050] The formation loss system includes an airbag 3, which is provided with a barometer 7, and an air pressure regulating valve 6 and an air pump 8 at the gas nozzle of the airbag; the airbag 3 is used to simulate the tunnel model;

[0051] The loading system is arranged on the upper part of the U-shaped movable steel frame 1, including a force component plate 11 above the similar soil 2, and a plurality of jacks 10 are arranged on the force force plate 11; in this embodiment, there are 8 force for...

Embodiment 2

[0063] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0064] The similar soil is circular and is used to simulate the soil layer around the tunnel; the steel rod adopts three kinds of circular steel rods with different size cross-sections, which can reach the most dense state; The long axes are respectively 3mm, 4mm, 5mm similar soil; the longitudinal length of the steel bar is equal to the longitudinal length of the airbag.

Embodiment 3

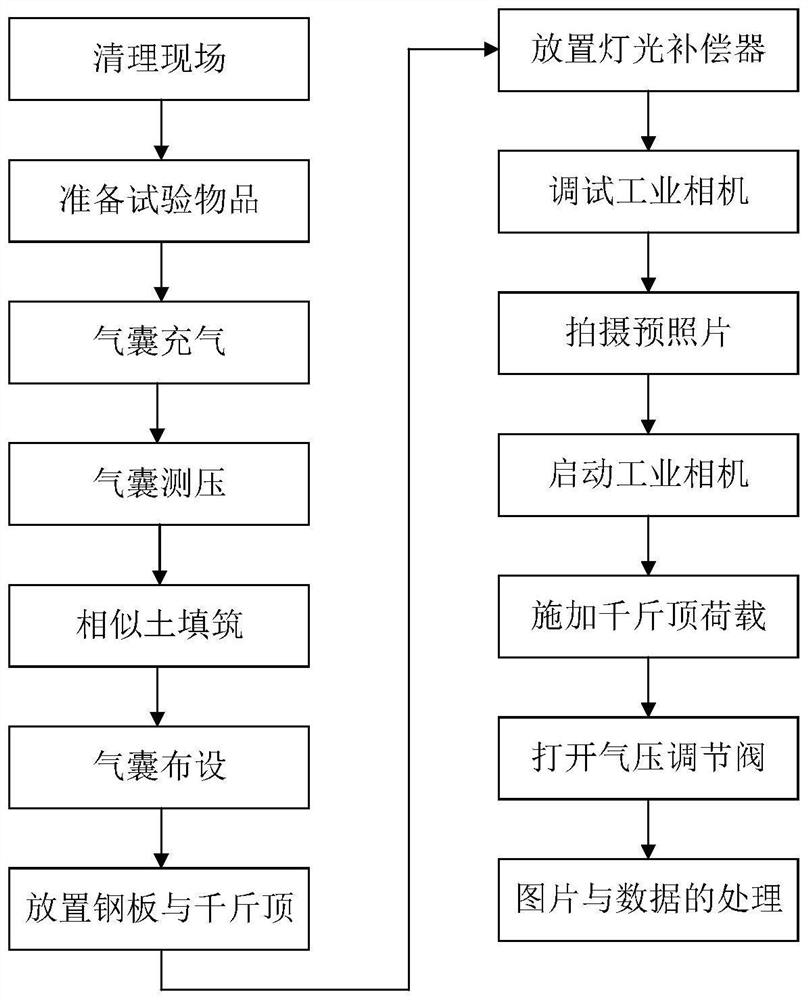

[0066] This embodiment provides a two-dimensional test method for simulating formation loss during tunnel excavation, as shown in the attached figure 1 As shown, it is a flow chart of the steps of the test model of formation loss caused by tunnel excavation on formation deformation and surface settlement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com