Reflective powder coating for traffic signs and preparation method thereof

A technology for powder coatings and traffic signs, applied in the field of chemical coatings, can solve problems such as no specific solutions, achieve excellent adhesion, ensure production quality, and simplify the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A reflective powder coating for traffic signs, made of the following components by weight: 20-40 parts of polyacrylic resin, 1-12 parts of antioxidant, 8-12 parts of curing agent, and 1-3 parts of leveling agent , 3-8 parts of mineral fusion oil, 0.5-1 part of benzoin, 1-2 parts of modified mixed nano filler, 5-10 parts of glass microspheres, 7-11 parts of hexamethyldisiloxane; wherein, the poly The hydroxyl value of the acrylic resin is 35-65 mgKOH / g.

[0034]Wherein, the antioxidant is one of 2,6-tertiary butyl-4-methylphenol and bis(3,5-tertiary butyl-4-hydroxyphenyl)sulfide. The curing agent is more than one of dicyandiamide, aliphatic amines, aromatic amines, imidazoles, polycarboxylic acids and urotropine curing agents. The leveling agent is one of polyacrylate, silicon-containing acrylate, polysiloxane or a combination thereof. The modified mixed nanofiller is barium sulfate, mica powder, strontium aluminate and titanium dioxide mixed according to the ratio of ...

Embodiment 2

[0042] A reflective powder coating for traffic signs, made of the following components by weight: 20 parts of polyacrylic resin, 12 parts of antioxidant, 8 parts of curing agent, 3 parts of leveling agent, 3 parts of mineral fusion oil, benzoin 1 part, 1 part of modified mixed nano filler, 10 parts of glass microspheres, 7 parts of hexamethyldisiloxane; wherein, the hydroxyl value of the polyacrylic resin is 65 mgKOH / g.

[0043] Wherein, the antioxidant is 2,6-tertiary butyl-4-methylphenol. The curing agent is dicyandiamide, aliphatic amines and aromatic amines mixed in a ratio of 1:2:1. The leveling agent is polyacrylate. The modified mixed nanofiller is a modified mixed nanofiller prepared by nano-modification technology after mixing barium sulfate, mica powder, strontium aluminate and titanium dioxide in a ratio of 1:2:1:3.

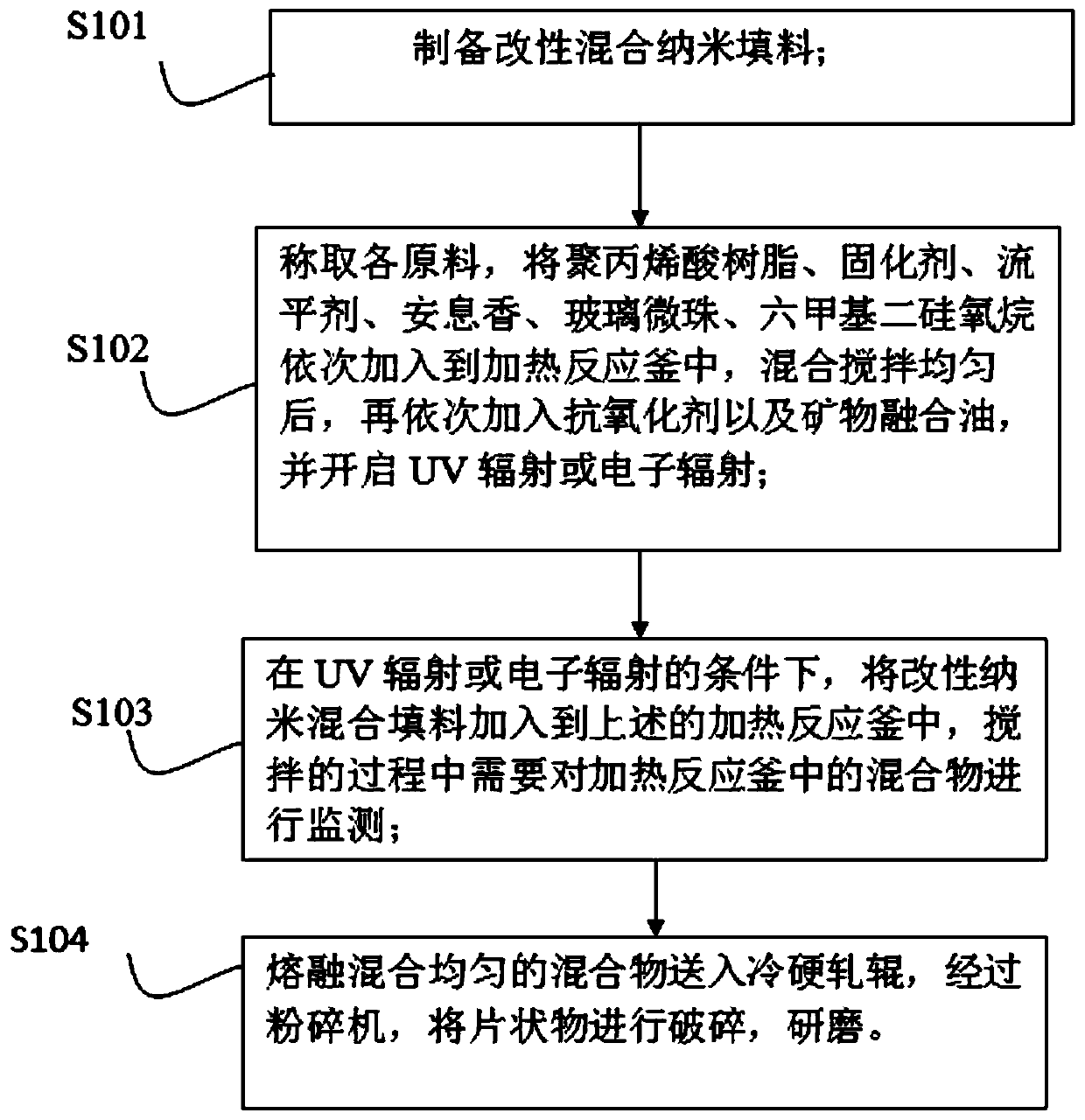

[0044] In addition, a preparation method of a reflective powder coating for traffic signs is also provided, comprising the steps of:

[0045] (1) P...

Embodiment 3

[0050] A reflective powder coating for traffic signs, which is made of the following components by weight: 40 parts of polyacrylic resin, 12 parts of antioxidant, 12 parts of curing agent, 3 parts of leveling agent, 3 parts of mineral fusion oil, benzoin 0.5 parts, 2 parts of modified mixed nanofillers, 10 parts of glass microspheres, and 7 parts of hexamethyldisiloxane; wherein, the hydroxyl value of the polyacrylic resin is 65 mgKOH / g.

[0051] Wherein, the antioxidant is one of bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide. The curing agent is a mixture of fatty amines and aromatic amines. The leveling agent is a mixture of polyacrylate and silicon-containing acrylate in a ratio of 1:1. The modified mixed nanofiller is a modified mixed nanofiller prepared by nano-modification technology after mixing barium sulfate, mica powder, strontium aluminate and titanium dioxide in a ratio of 5:7:1:1.

[0052] In addition, a preparation method of a reflective powder coating for tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com