An automatic recording system and automatic recording method for an anchor chain tensioner

An automatic recording and tension machine technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as influence and large tension load, achieve complete information recording, improve safety, and good measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate those of ordinary skill in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

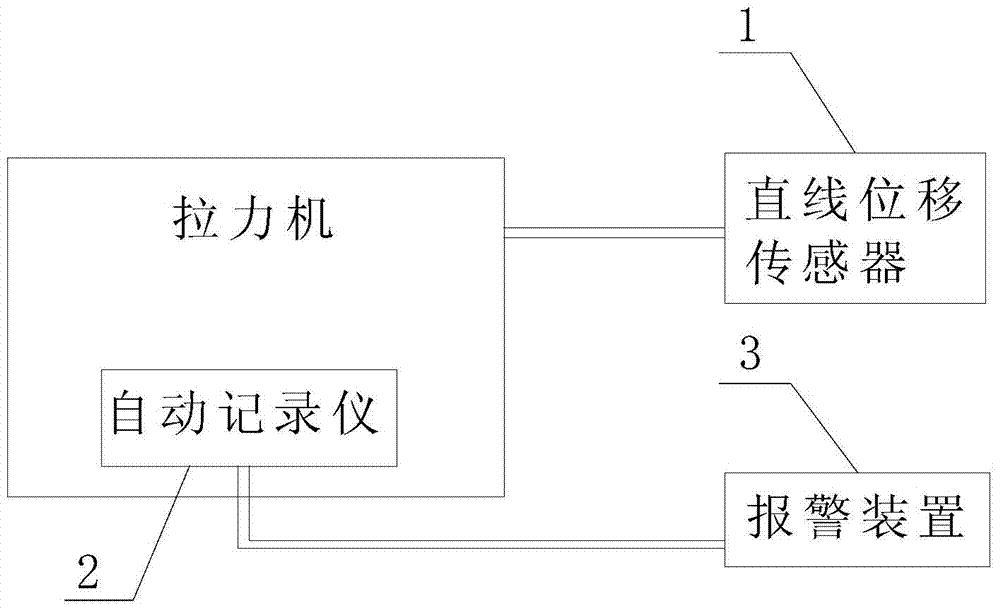

[0029] Such as figure 1 As shown, an automatic recording system for an anchor chain tensile machine includes: a linear displacement sensor 1 and an automatic recorder 2 . Wherein, the linear displacement sensor 1 is installed on the tensile machine to detect the length change of the anchor chain, and the automatic recorder 2 is connected with the linear displacement sensor 1 for recording and displaying the length change of the anchor chain.

[0030] In this embodiment, the linear displacement sensor 1 is preferably a VOLFA-LWF series electronic ruler, and the automatic recorder 2 is preferably an STR1000 automatic recorder from Jiangsu Shuntong Company; it is not limited to this embodiment.

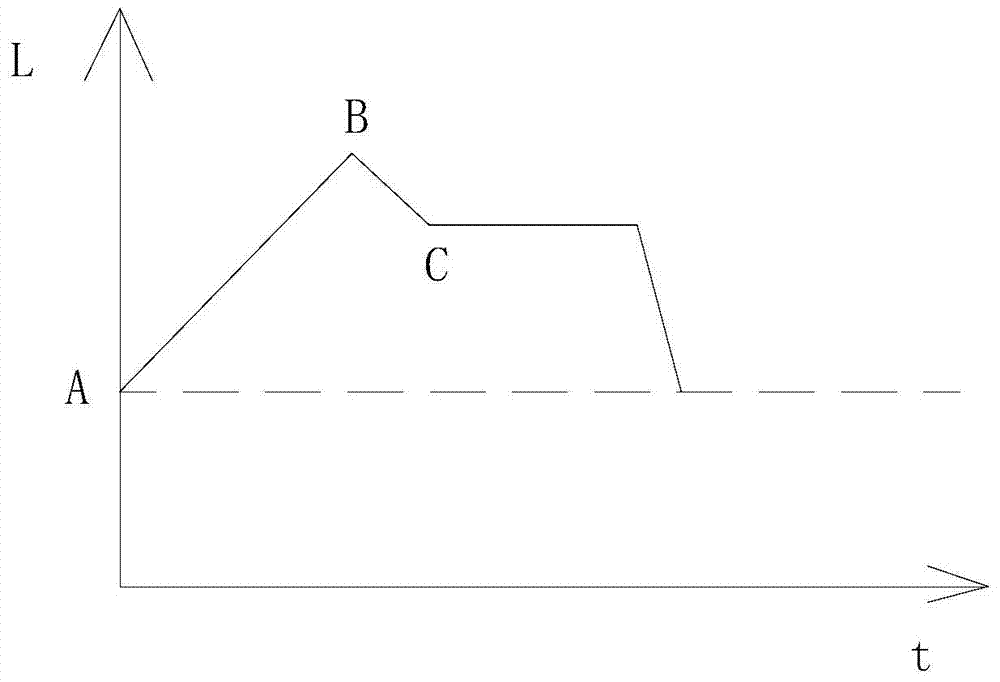

[0031] In particula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com