Automatic fool-proof laser engraving operation device

A kind of operating device and dumb technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of labor consumption, scrapped products, low detection efficiency, etc., improve detection and processing accuracy, and avoid manual measurement , the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

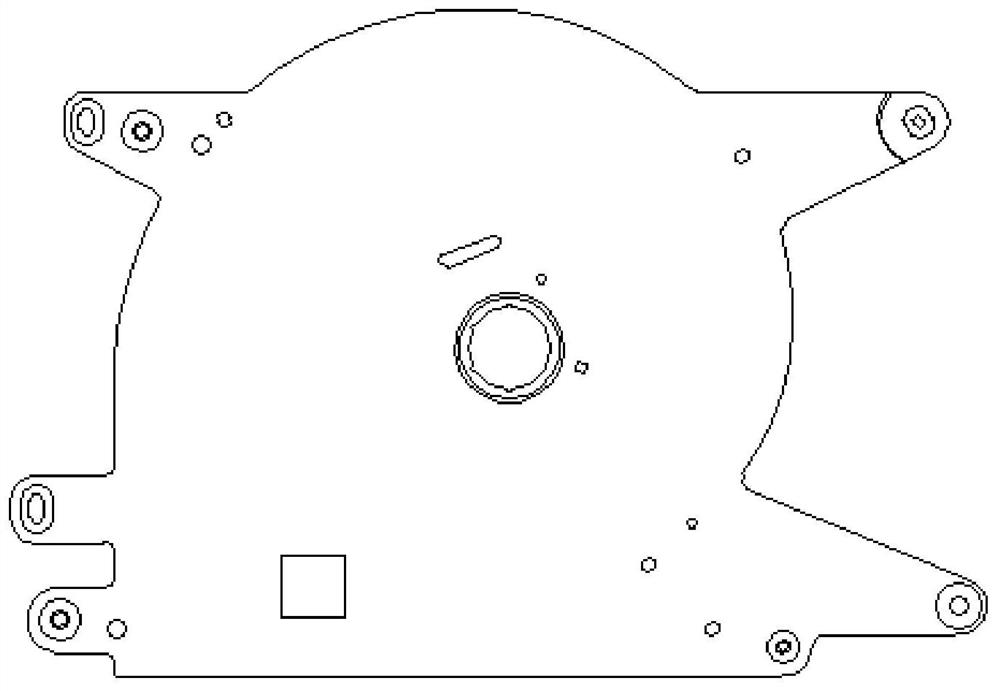

Image

Examples

Embodiment

[0023] Embodiment: an automatic fool-proof laser engraving operation device, including a laser engraving machine, a radium engraving fixture 1, a controller and an induction needle 2, the radium engraving fixture 1 can be fixedly installed on the laser engraving machine workbench, A positioning groove 3 matching the shape of the workpiece to be processed is formed on the laser engraving fixture 1, and the sensing needle 2 is fixedly installed on the bottom surface of the positioning groove 3. At least one sensing point 4 is provided on the sensing pin 2, and each sensing point 4 can The distance between it and the product 7 positioned in the positioning groove 3 is detected, and the sensing needle 2 is electrically connected and communicated with the controller, and the controller controls the start and stop of the laser engraving machine. When the product 7 is processed by laser engraving, place the product 7 in the radium engraving fixture 1 for positioning. The designated p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com