Gasket thickness prediction tool and method of use thereof

A gasket and tooling technology, which is applied in the field of gasket thickness prediction tooling, can solve the problems of error accumulation, measurement accuracy and low work efficiency, and achieve the effects of reducing measurement errors, short measurement time, and accurate electronic measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

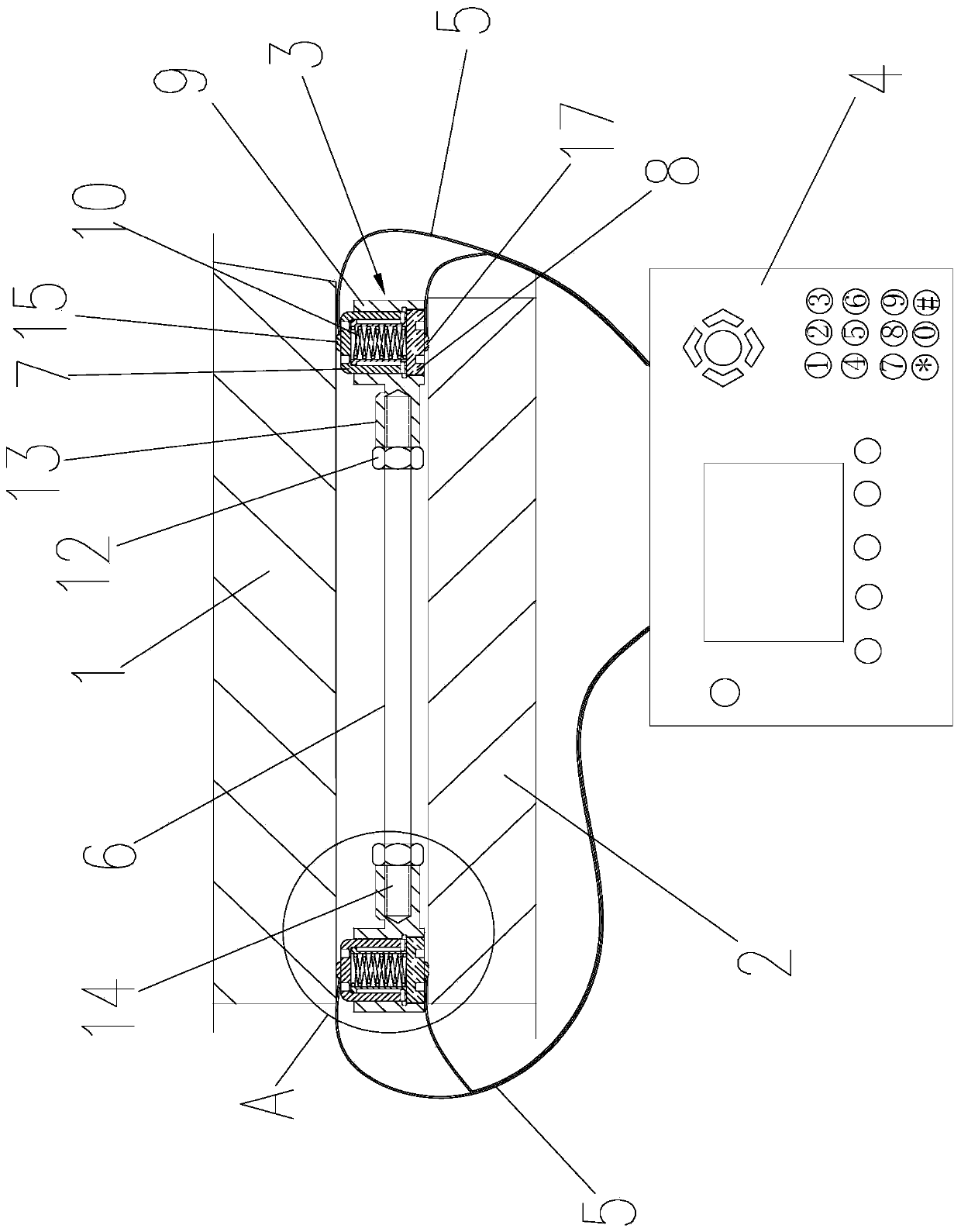

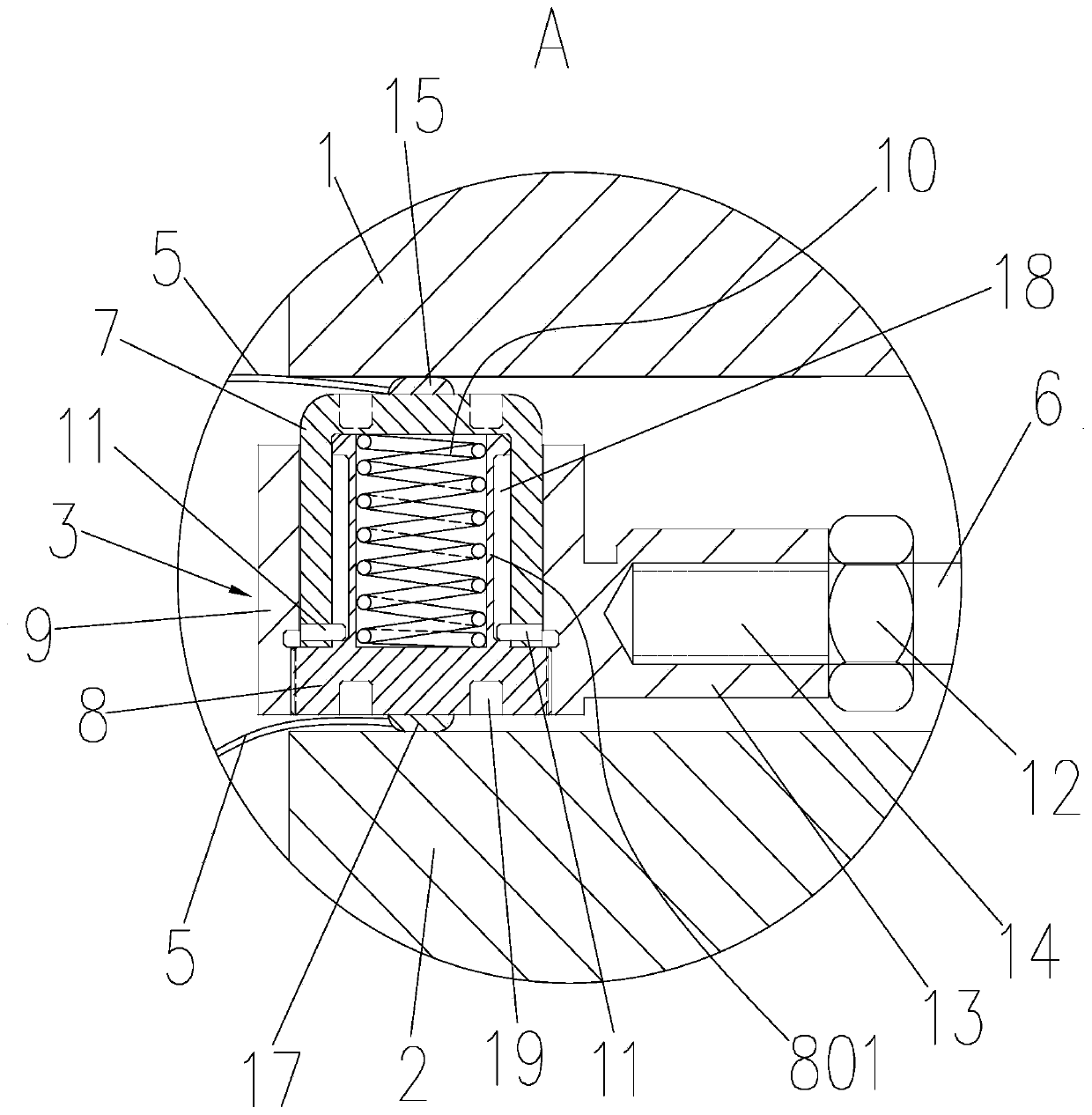

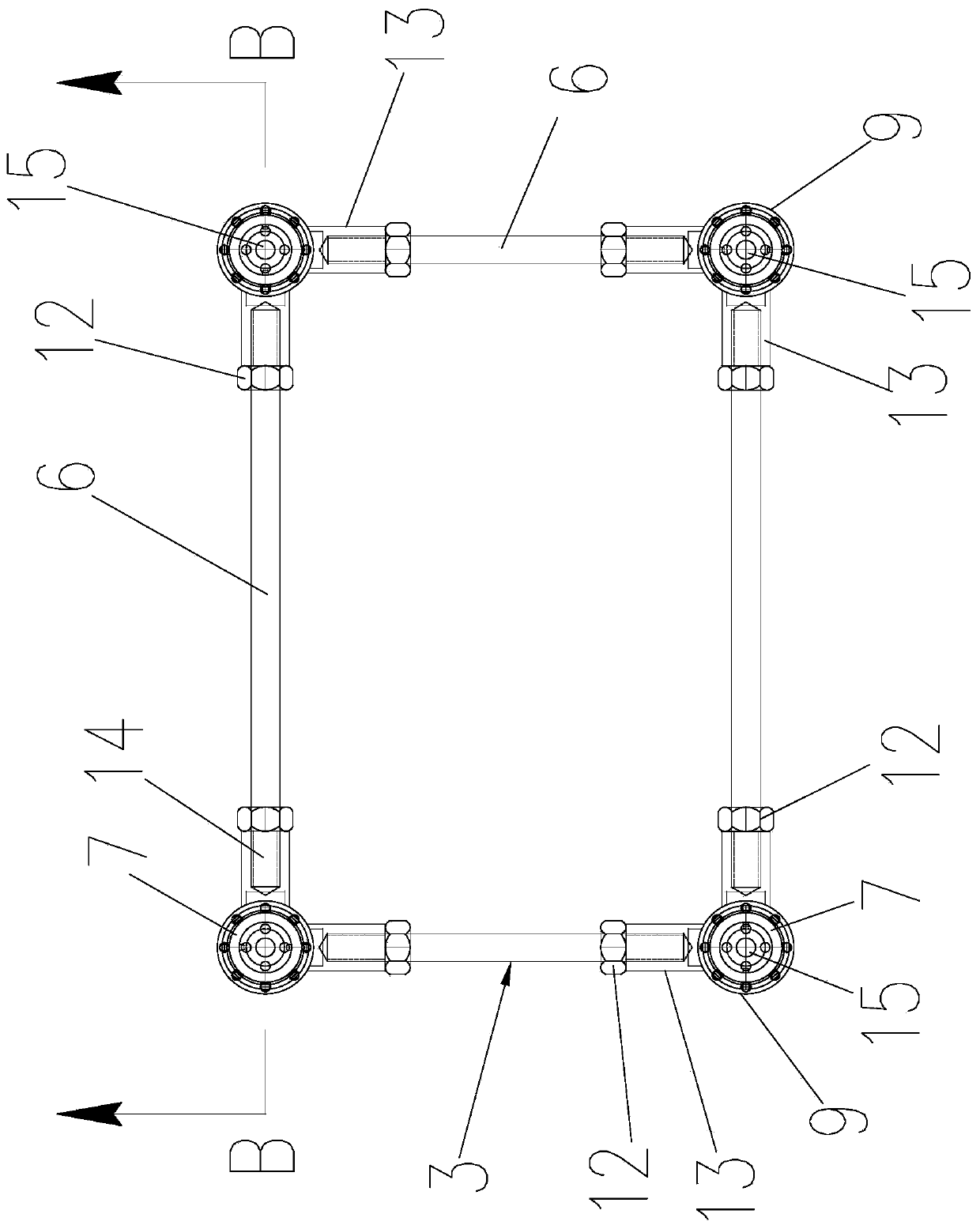

[0081] Such as Figure 1-Figure 11 The shown embodiment one of a gasket thickness prediction tool of the present invention includes a gasket measuring device 3 and a gap measuring device; the gasket measuring device 3 includes several sets of measuring units, and each measuring unit includes a cover 7 and a gap measuring device. The base 8, the cover 7 is covered on the base 8, the spring 10 is sandwiched between the cover 7 and the base 8, and the stretching direction of each spring 10 is consistent; the gap measuring device includes a first electrode plate 15, a second electrode plate 17 and The device body 4, the first electrode plate 15 is installed on the outer top surface of the cover 7, the second electrode plate 17 is installed on the lower bottom surface of the base 8 away from the cover 7, the first electrode plate 15 and the outer top of the cover 7 An insulating film is spaced between the surfaces and between the second electrode plate 17 and the lower bottom surfa...

Embodiment 2

[0107] Such as figure 1 , 2 and Embodiment 2 of a gasket thickness prediction tool of the present invention shown in 5-11. The difference between this embodiment and Embodiment 1 is that the gasket whose thickness is to be predicted is circular, and the positions of the measuring units are connected to each other in the center. The line is an inscribed polygon of the outer circle of the gasket. The more the number of measuring units, the more accurate the measured results. This embodiment can be applied to circular gaskets, and its advantages are the same as those of Embodiment 1. Therefore, the present invention can be applied to all Types of shim thickness predictions.

[0108] Furthermore, a plurality of tool holes 19 are evenly distributed around the center circumference on the lower bottom surface of the base 8 , and the base 8 can be rotated and screwed into the seat tube 9 by a matching wrench, which makes installation more convenient.

[0109] Other structures of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com