Stackable automatic leveling supporting leg structure

A technology of automatic leveling and supporting feet, applied in the field of supporting feet, can solve problems such as inability to apply to a table, weak physical strength, and inability to operate effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

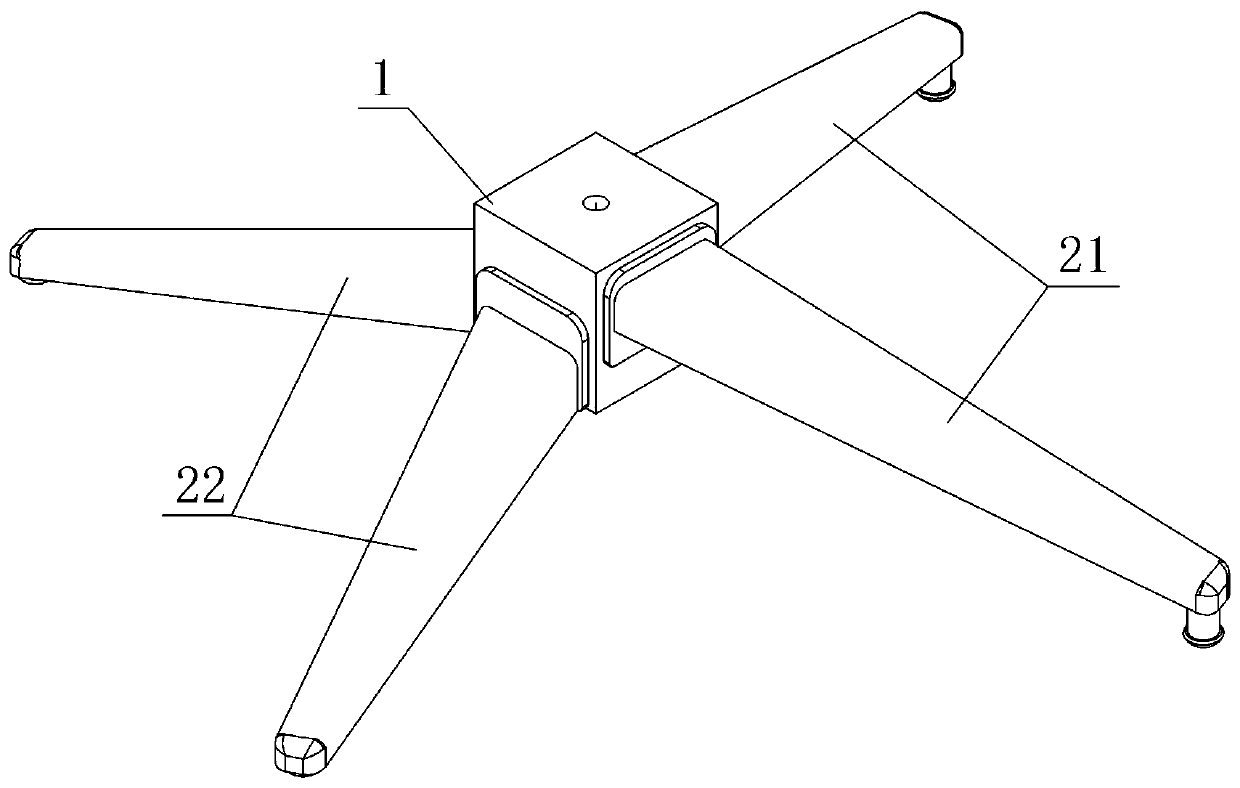

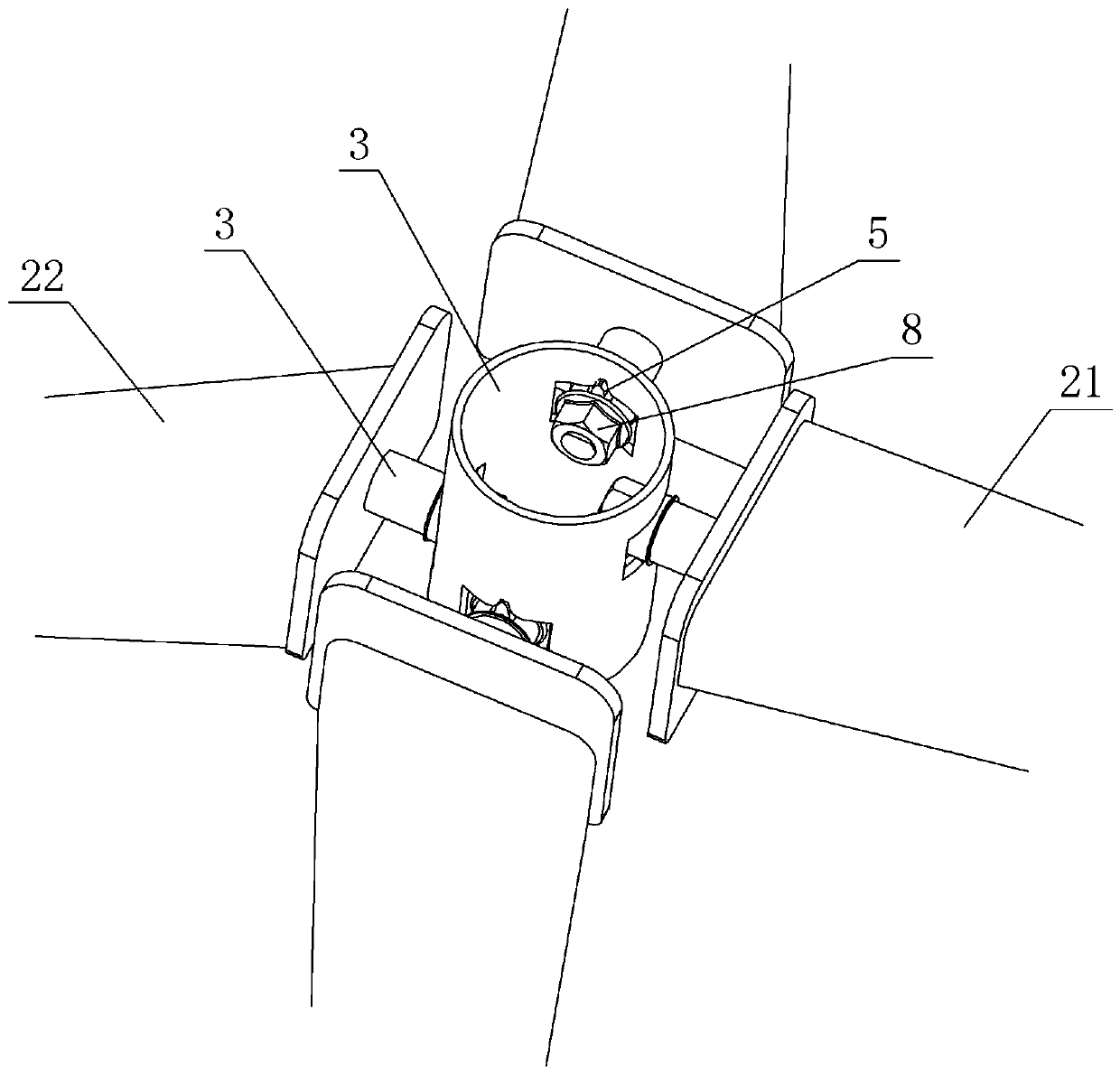

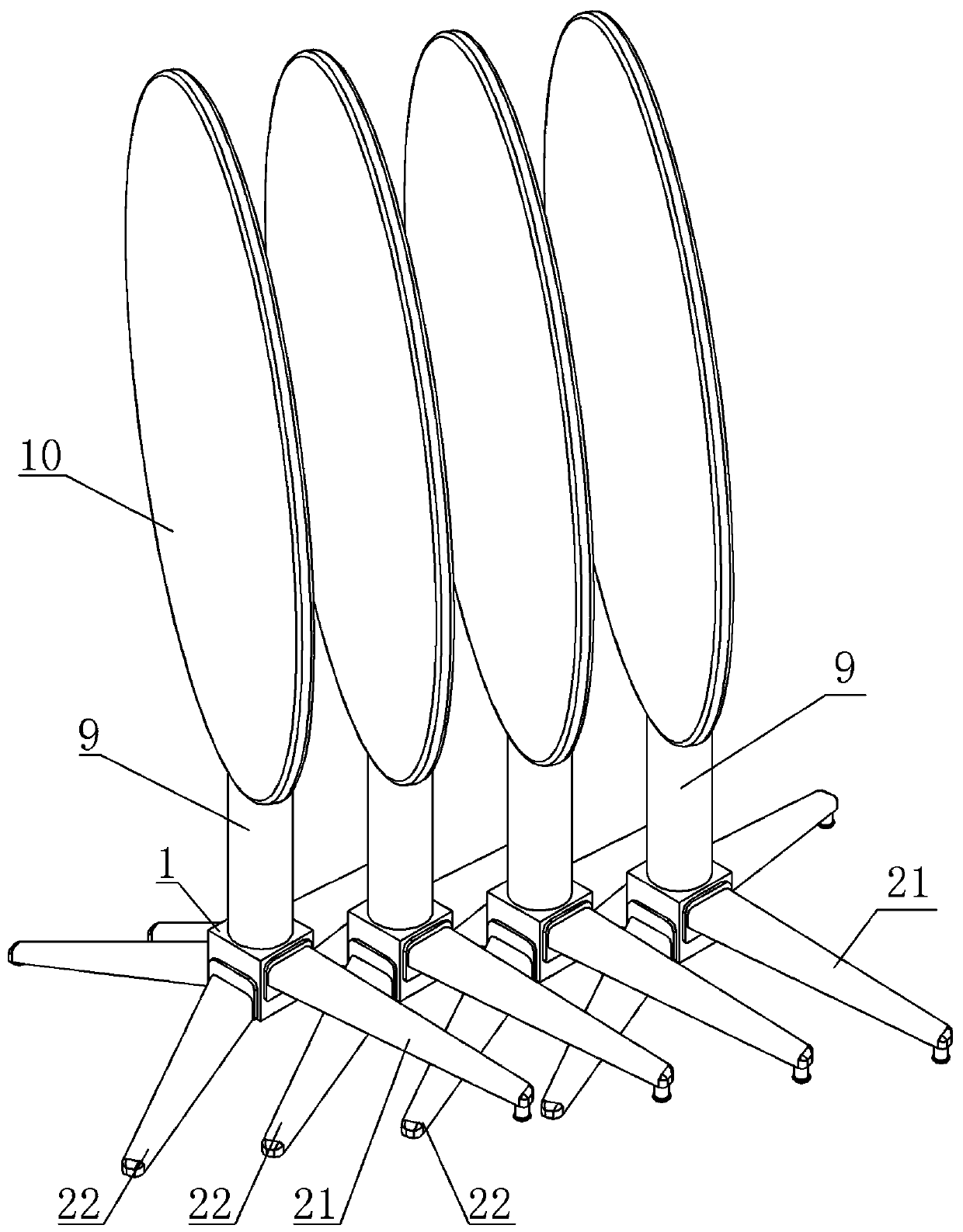

[0014] A stackable automatic leveling support foot structure, including a fixed base 1 fixedly installed under the object, a plurality of supporting legs 2 are installed on the outer wall of the fixed base along the circumferential direction, the supporting legs are arranged obliquely and part of the supporting legs and the fixed base The installation heights are different; a cylindrical and rotatable torque ring 3 is installed in the fixed seat, the rotation axis of the torsion ring is vertical, and the outer wall of the torsion ring is provided with a torsion groove 31 facing each support foot; on the support foot A connecting column 4 is installed. The connecting column extends through the fixing seat into the torsion groove of the torsion ring. A shift tooth 5 is arranged between the connecting column and the torsion groove, and between the connecting column and the shift tooth, between the shift tooth and the torsion groove A limit structure for limiting rotation around a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com