Synchronous register impressing system and impressing method

An embossing machine and control system technology, which is applied in the field of synchronous embossing embossing system, can solve the problems of insufficient indentation depth, easy blurring, deviation of finished pattern and pattern, etc., and achieve the effect of long embossing time and high simulation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

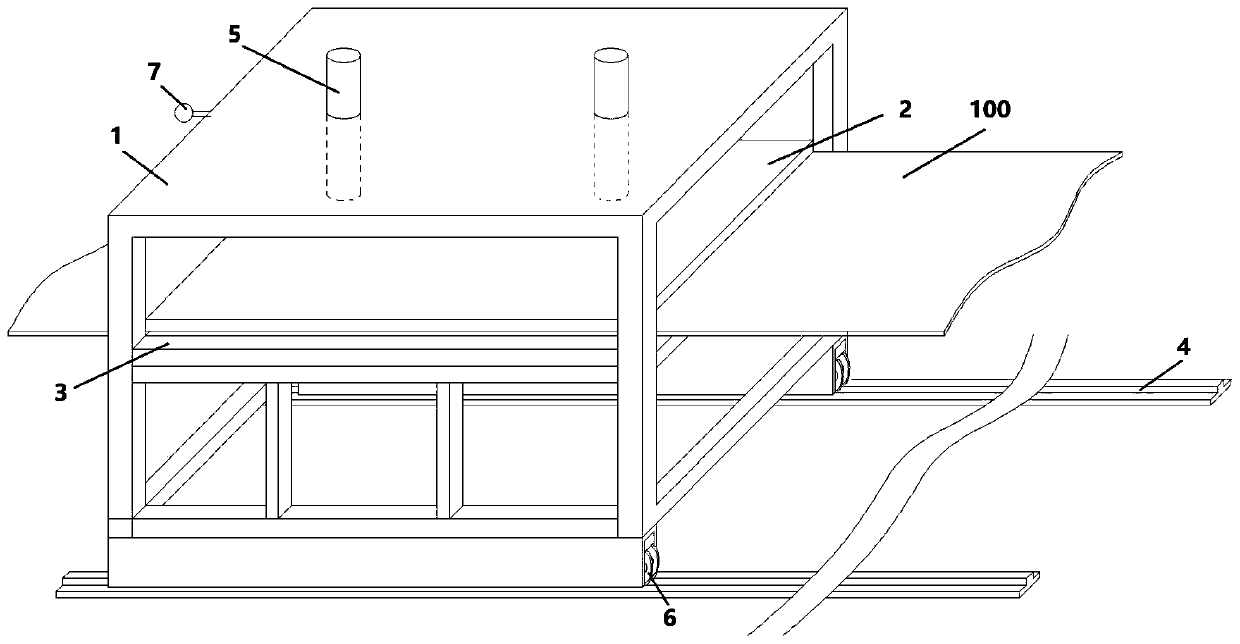

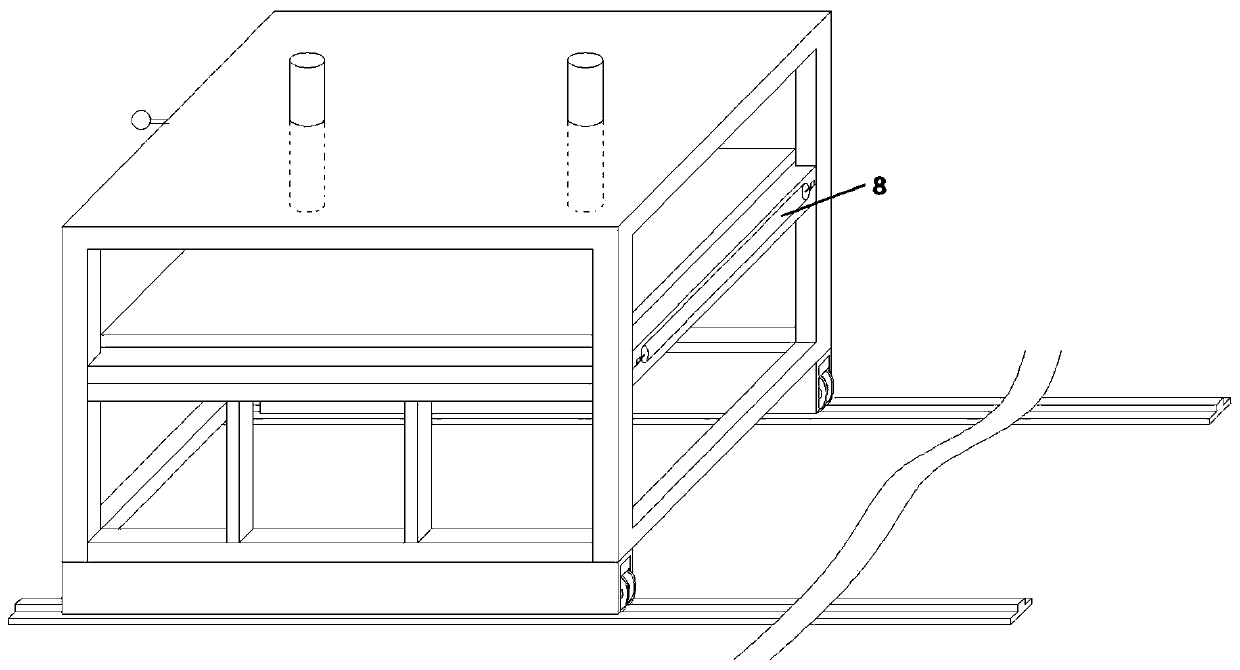

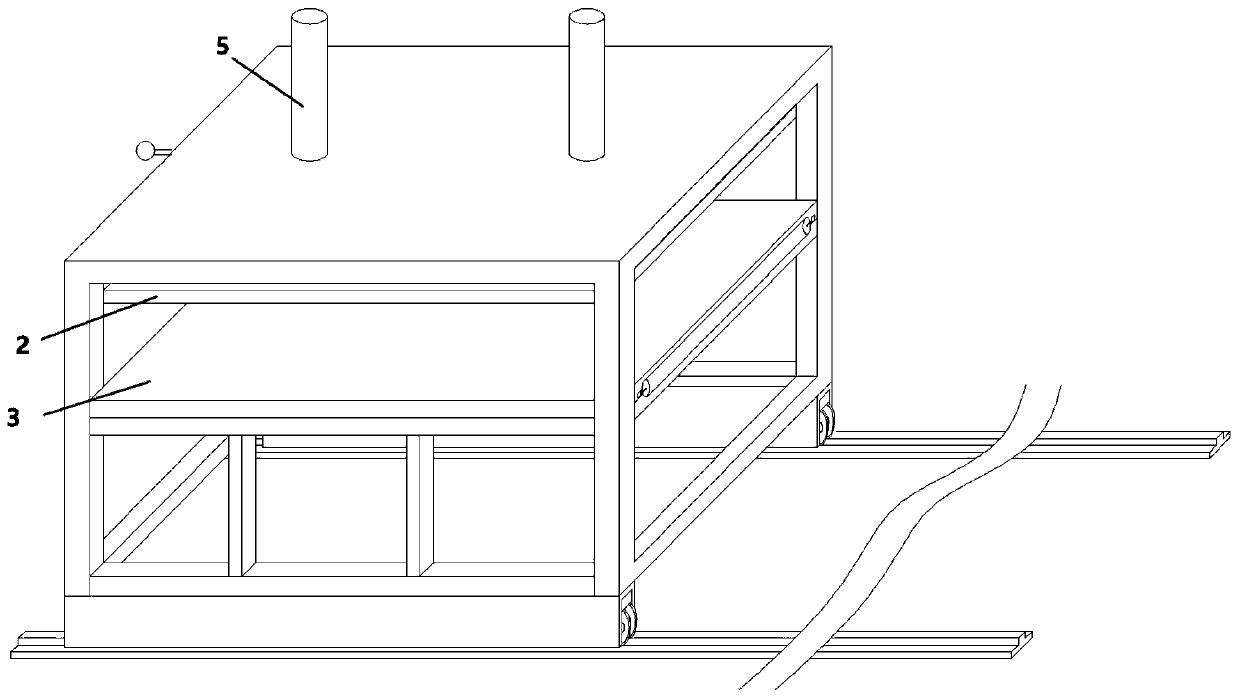

[0036] Such as Figure 1-4 As shown, the synchronous embossing system includes a embossing machine and a plate 100 to be embossed, and is characterized in that: the imprinting machine includes a frame 1, an upper platen 2, a lower platen 3, and a guide rail 4. The upper pressing plate is connected to the top of the frame through the pressing down driving device 5, the lower pressing plate is arranged in the middle of the frame, the bottom of the frame is provided with a roller 6 matching the guide rail, and the length of the guide rail is greater than or equal to the length of the frame*2 , also includes a frame driving device (not shown in the figure), which is used to drive the frame to move on the guide rail. Pattern, the width of the upper platen is equal to or slightly wider than the plate, and the size of the lower platen and the upper platen is equal or slightly larger than the upper platen.

[0037]The embossing machine also includes an image recognition system 7 and ...

Embodiment 2

[0041] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that it also includes a deviation correction device arranged on the lower platen. The deviation correction device is two hydraulic push rods 9 arranged symmetrically. On both sides of the feeding direction of the embossing machine, the image recognition system is located in the middle of the frame above the feeding side of the embossing machine, and the plate to be embossed is provided with a centerline mark on the centerline of the starting position of each unit, so The centerline position of the rack is pre-recorded in the above image recognition system, and the image recognition system sends both the centerline position of the rack and the signal of the centerline mark to the control system, and the control system compares the centerline mark with the centerline position of the rack, and if the centerline If the position of the mark is to the left relative to the center l...

Embodiment 3

[0043] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is that it also includes a heating device (not shown in the figure) for uniformly heating the upper platen, and conventional heating devices can be used, such as electric heating and thermal oil heating.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap