A vertical connection structure of a prefabricated shear wall structure

A technology for connecting structures and shear walls, which is applied to structural elements, walls, building components, etc., can solve the problems that are not conducive to improving the construction speed of prefabricated industrialized houses, the reliability and strength of joints are low, and the assembly construction is difficult.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

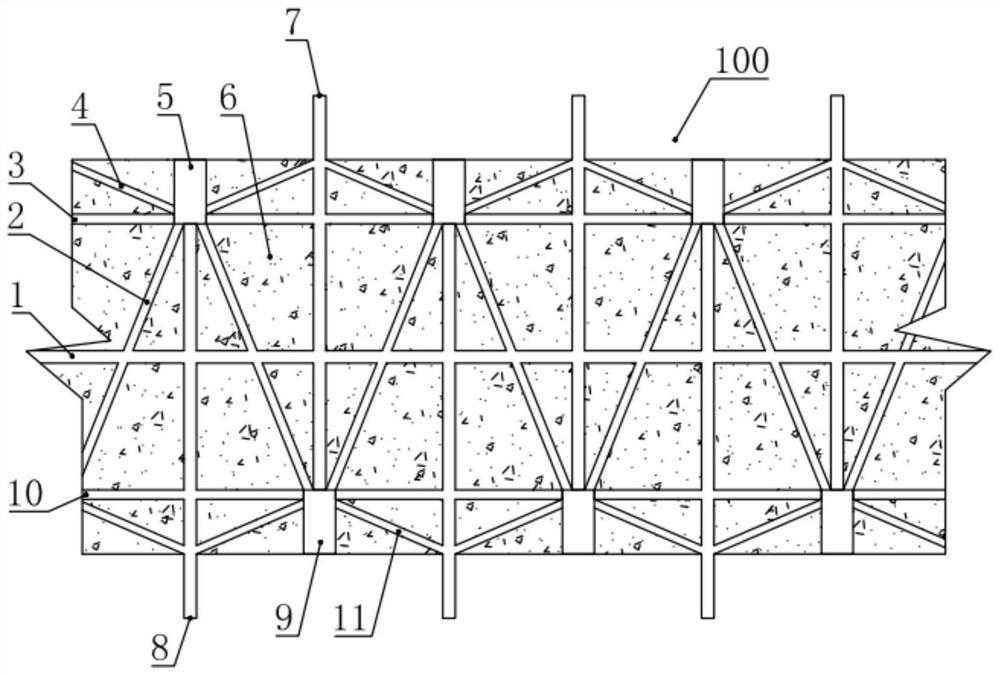

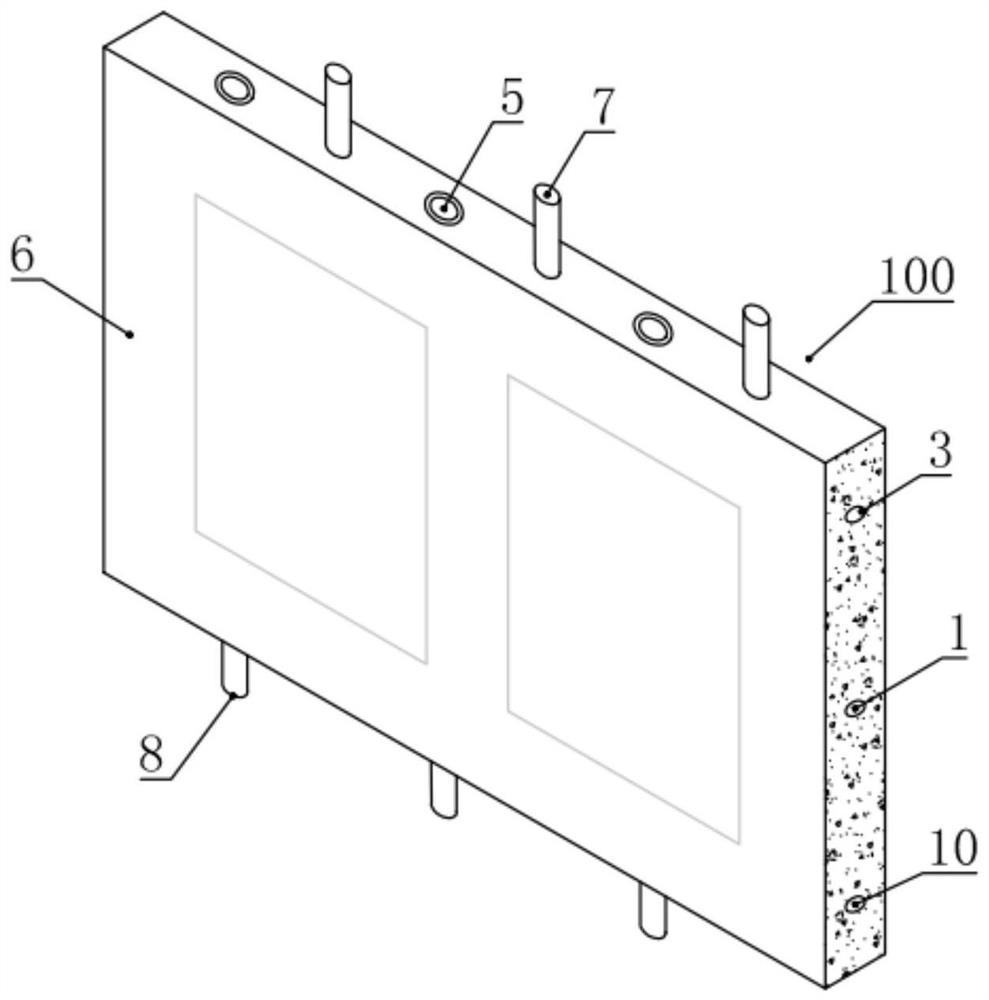

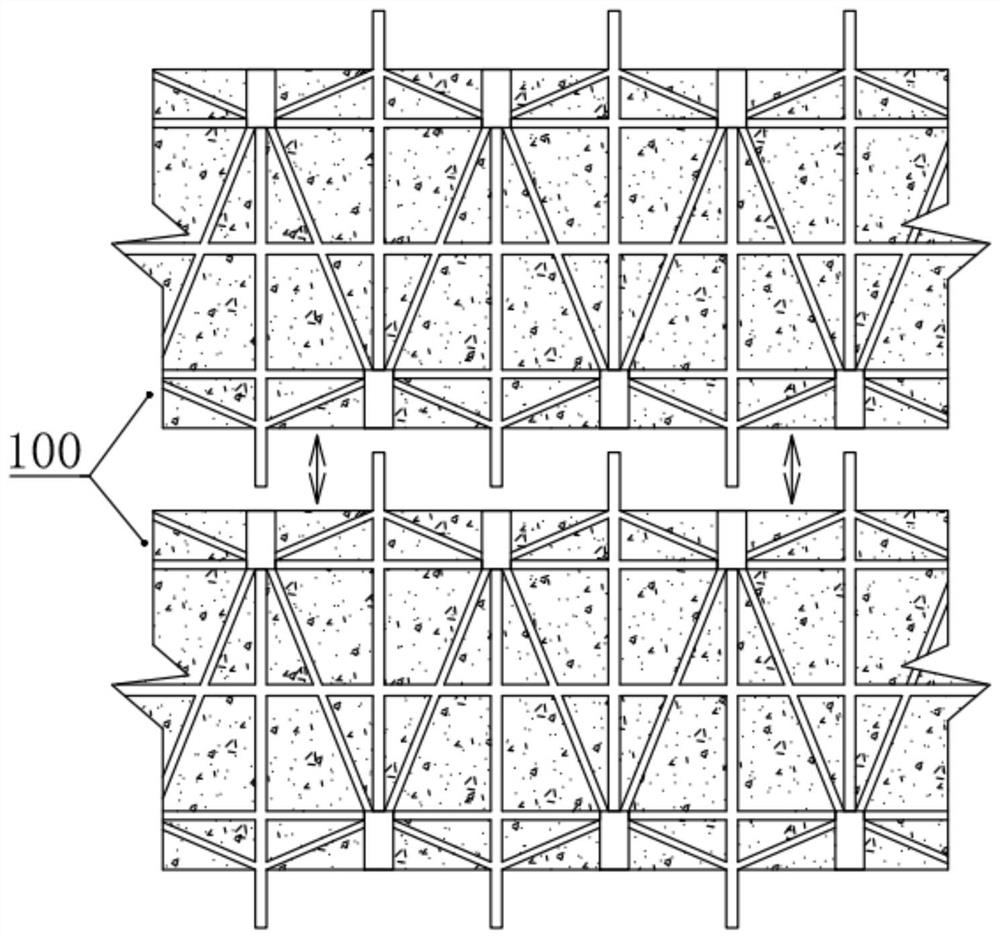

[0026] see Figure 1-2 , in an embodiment of the present invention, a prefabricated shear wall structure vertical connection structure includes prefabricated shear wall modules 100 that can be assembled and connected vertically, and the prefabricated shear wall modules 100 include several horizontally staggered The first plug-in assembly and the second plug-in assembly, several of the first plug-in assemblies and the second plug-in assemblies are horizontally installed and fixed with upper horizontal ribs 3, middle horizontal ribs 1 and lower horizontal ribs 10 from top to bottom. The upper diagonal bracing bar 4 connected with the first insertion rib 7 in the middle is also installed and fixed between the two adjacent upper connecting cylinders 5, and the two adjacent lower connecting cylinders 9 are also installed and fixed. There is a lower diagonal brace 11 connected to the second plug-in rib 8 in the middle, and a middle diagonal brace 2 is installed and fixed between the...

Embodiment 2

[0028] see Figure 1-2 , the difference between this embodiment and embodiment 1 is:

[0029] Further, a number of the first plug-in assemblies and the second plug-in assemblies are vertically and evenly staggered; the first plug-in assemblies include an upper connecting cylinder 5 and a second plug-in rib 8 that can be mated for plugging. The second plugging rib 8 is installed and fixed on the lower end of the upper connecting cylinder 5; the second plugging assembly includes a first plugging rib 7 and a lower connecting tube 9 that can be mated and plugged, and the first plugging rib 7 is installed It is fixed on the upper end of the lower connection cylinder 9; the length of the first insertion rib 7 protruding from the upper end surface of the upper connection cylinder 5 is the same as the length of the second insertion rib 8 protruding from the lower end surface of the lower connection cylinder 9 .

[0030] Further, the upper horizontal rib 3 is flush with the lower end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com