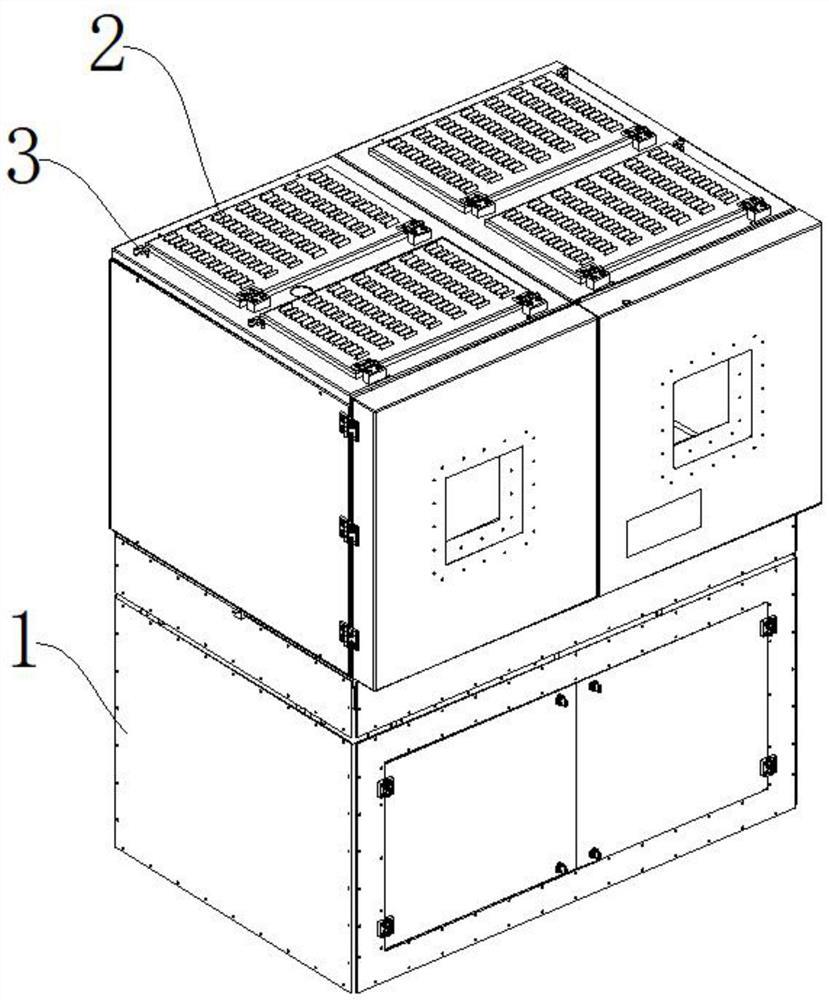

An electrical switch cabinet pressure relief device

A technology of electrical switch and pressure relief device, which is applied in the cooling/ventilation of substation/switchgear, details of substation/switch layout, substation/power distribution device shell, etc., which can solve the problems of low reliability, failure to open automatically, and bolt damage and other issues, to avoid injury to the staff, to ensure the effect of pressure relief, and to improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

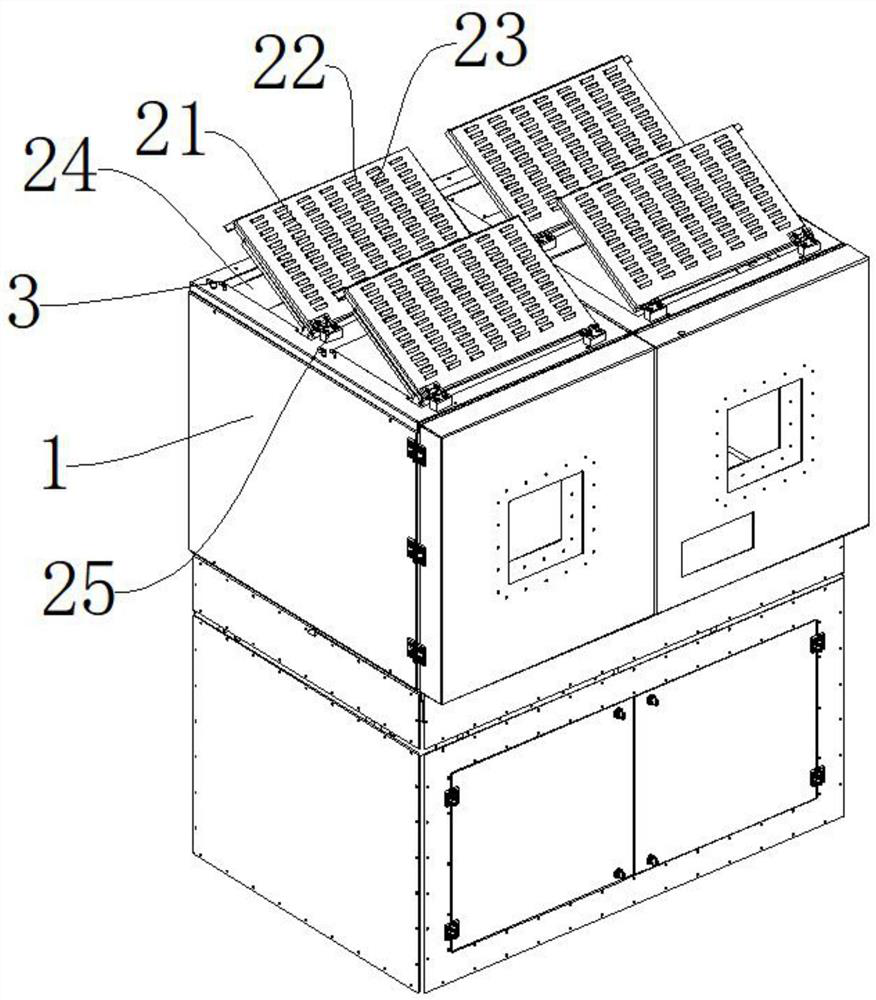

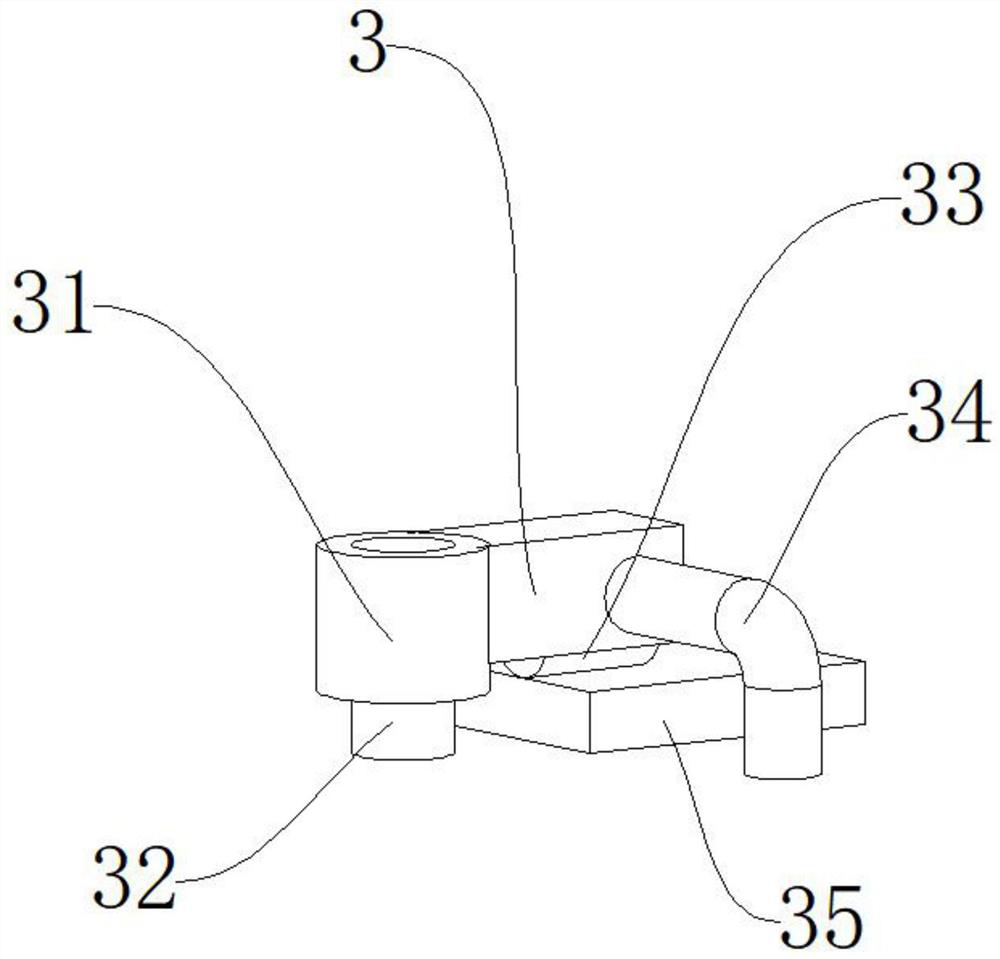

[0044] Such as Figure 1-Figure 6 As shown, the opening aid mechanism 4 includes a rotating plate 41, a universal joint 42, a pulling spring 43, and a detection switch 44. The rotating plate 41 is connected to the cover plate 21 of the pressure relief mechanism 2 by welding, and one end of the rotating plate 41 is connected to the universal joint 42. The universal joint 42 is connected to the electrical switch cabinet 1 through the pulling spring 43, and the other end of the rotating plate 41 is provided with a detection switch 44. When the locking mechanism 3 releases the pressure relief mechanism 2, the pulling spring 43 pulls the universal joint 42 and the rotating plate 41 , so that the cover plate 21 is flipped open, and the detection switch 44 is separated from the rotating plate 41 at the same time, thereby sending an alarm signal to the processor; Ventilation holes 22 are formed on the top, and the upper end of the cover plate 21 is connected to the arc-shaped plate 23...

Embodiment 2

[0047] Such as Figure 7 The difference between the present embodiment and embodiment 1 is that the opening-assisting mechanism 4 includes a rotating plate 41, a universal joint 42, a cylinder barrel 411, and a pulling cylinder 412, and the rotating plate 41 is connected to the cover plate 21 of the pressure relief mechanism 2 by welding, and the rotation One end of the plate 41 is connected to the universal joint 42, the other end of the rotating plate 41 is provided with a detection switch 44, the universal joint 42 is connected to the cylinder barrel 411, the inside of the cylinder barrel 411 is connected to the pulling cylinder 412, and the pulling cylinder 412 is connected to the electrical switch cabinet 1, and the cylinder The barrel 411 cooperates with the pulling cylinder 412. After the locking mechanism 3 releases the cover plate 21, the negative pressure inside the cylinder barrel 411 and the pulling cylinder 412 shrinks the cylinder barrel 411 and the pulling cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com