A kind of mems microphone chip with dustproof structure and manufacturing method thereof

A dust-proof structure and microphone technology, applied in sensor parts, microphone port/microphone accessories, sensors, etc., can solve the problem that dust particles are easy to enter the chip, affect the performance and reliability of MEMS microphones, enter the diaphragm and between backplanes, etc., to avoid damage to chip performance, avoid accumulation of dust particles, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1: as Figure 3-Figure 4 Shown, a kind of MEMS microphone chip with dust-proof structure provided by the invention comprises:

[0069] The substrate 10 is provided with a back cavity 11 penetrating vertically;

[0070] The diaphragm 30 is arranged at intervals on one side of the substrate 10, and at least part of the diaphragm 30 is movably arranged above the back cavity 11;

[0071] The back plate 50 is arranged at intervals on the side of the diaphragm 30 away from the substrate 10; the back plate 50 is also provided with a plurality of through holes 53 arranged at intervals and penetrating the back plate 50 vertically;

[0072] The vibration gap 43 is arranged between the diaphragm 30 and the back plate 50, and forms a capacitor structure together with the diaphragm 30 and the back plate 50;

[0073] The sacrificial layer 40 is located between the diaphragm 30 and the back plate 50 and outside the vibration gap 43;

[0074] The insulating layer 20 is lo...

Embodiment 2

[0093] Example 2: See Figure 5 , in this embodiment of the present invention, backplane 50 can adopt the sandwich structure thin film that silicon nitride / doped polysilicon / silicon nitride are compounded, and at this moment, dust-proof structure 42 is made of the silicon nitride of backplane 50 Layer formation, since silicon nitride is electrically insulating, there is no need to form isolation trenches 54 . The remaining parts in this embodiment are the same as in Embodiment 1.

Embodiment 3

[0094] Embodiment 3: the present invention also provides the manufacturing method of the above-mentioned MEMS microphone chip with dust-proof structure, please refer to Image 6 , including the following steps:

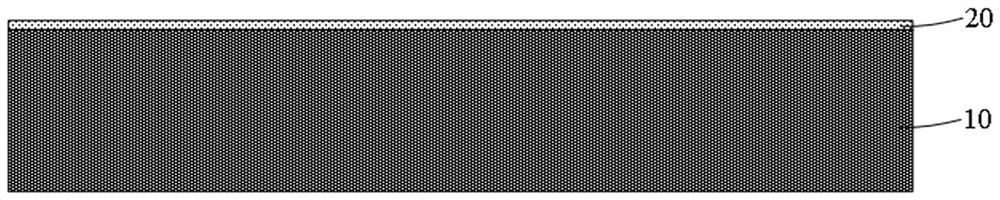

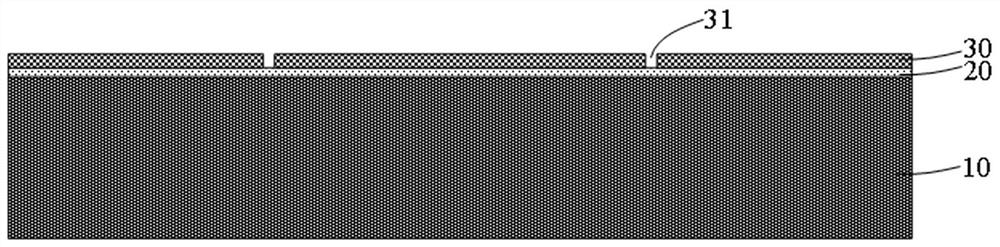

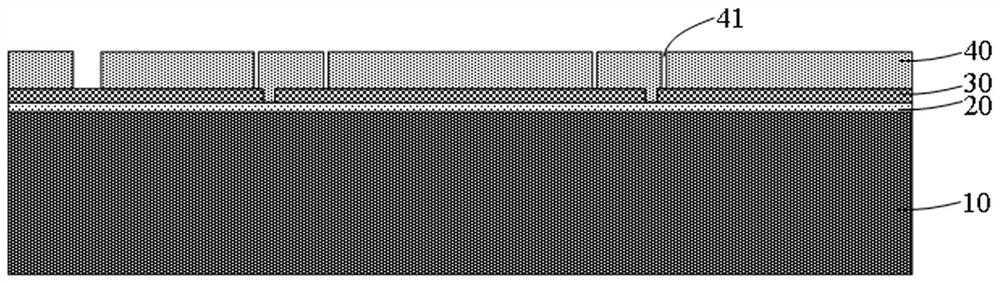

[0095] S1: Provide a substrate 10, form an insulating layer 20 and a diaphragm 30 on the substrate 10, and partially etch a gas release valve 31 on the diaphragm 30, as Figure 7a-Figure 7b shown;

[0096] Specifically, the substrate 10 is a double-sided polished semiconductor substrate, including but not limited to a silicon substrate, a germanium substrate, and a silicon carbide substrate; in an embodiment of the present invention, the substrate 10 is double-sided polished single crystal silicon substrate.

[0097] Specifically, the insulating layer 20 is made of silicon oxide, which can be formed by thermal oxidation, low pressure chemical vapor deposition, or plasma chemical vapor deposition; in the embodiment of the present invention, the insulating layer 20 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com