Agricultural tilling assembly and components

A component and agricultural technology, applied in agricultural machinery and implements, agriculture, plows, etc., can solve problems that have not been widely adopted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

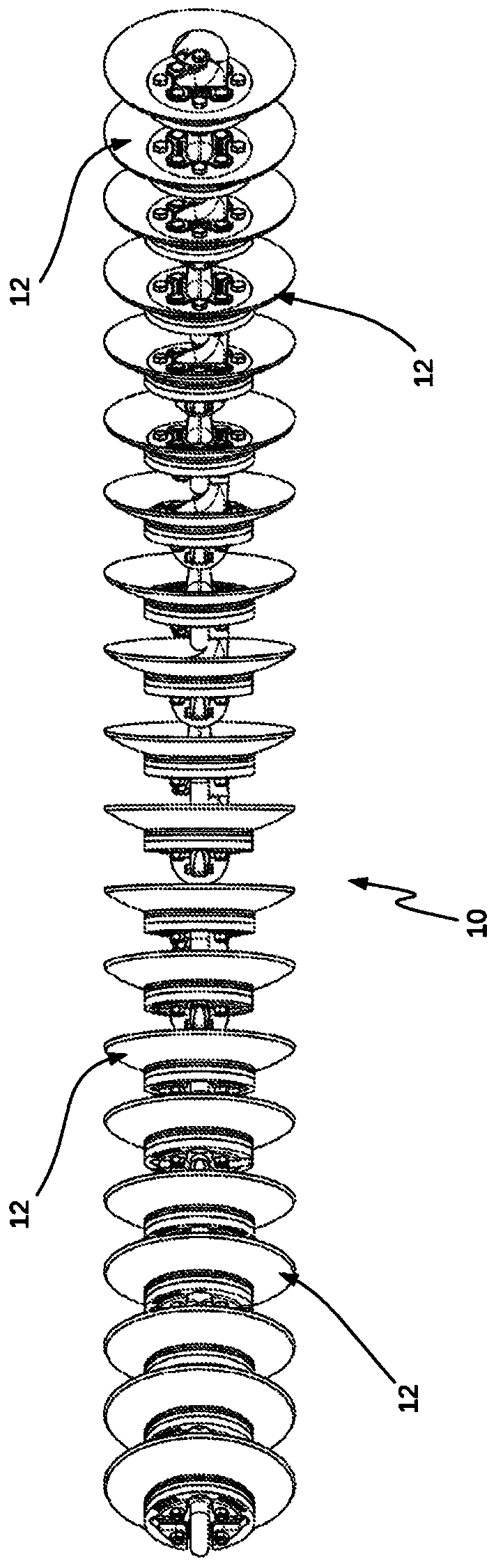

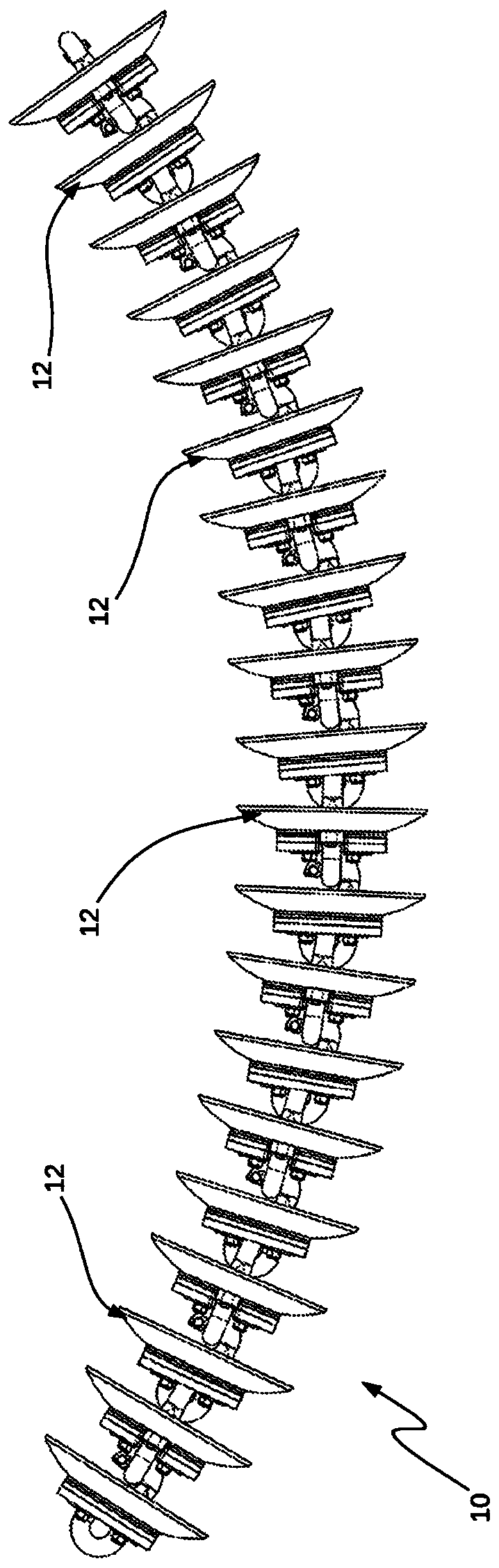

[0167] figure 1 and figure 2 An agricultural tillage assembly according to an embodiment of the invention is shown. In this particular embodiment, the tillage assembly is an agricultural disc chain harrow 10 . The disc chain rake 10 has an elongated structure, and in this embodiment, a plurality of ground engaging tool subassemblies 12 are secured within the elongated structure. As can be understood from the description below, in this embodiment, the ground engaging tool subassembly 12 is assembled to form an elongated structure.

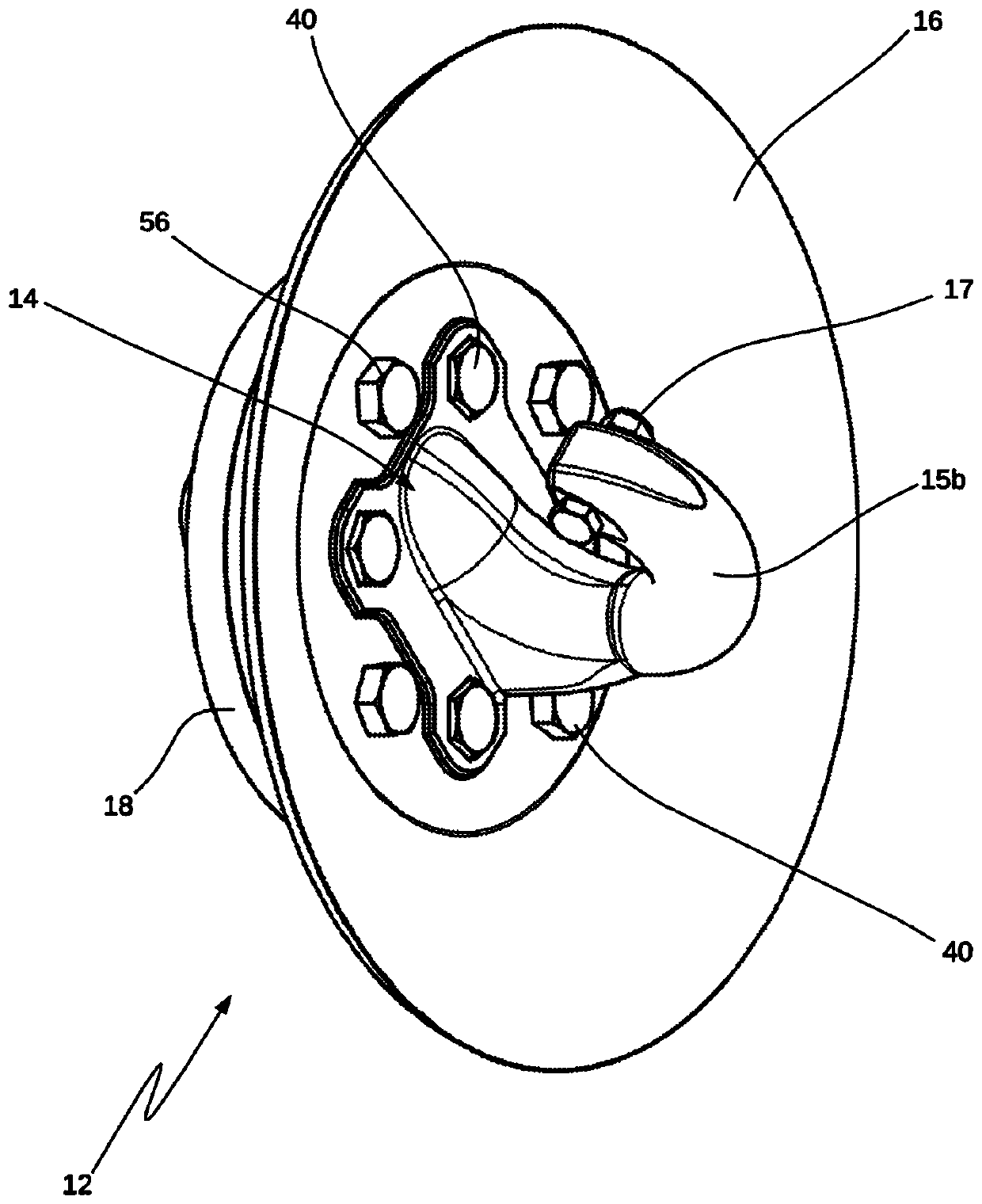

[0168] Figure 3 to Figure 15 One of the subassemblies 12 and its component parts are shown in detail. For simplicity, the descriptions of these figures will generally refer to a single subassembly 12 .

[0169] Subassembly 12 includes hub 14 , ground engaging tool 16 and counterweight 18 . In these figures, the ground engaging tool 16 is a disc, but it should be understood that the invention is not limited to discs. In this example, the puc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap