Floor nozzle for a vacuum cleaner

A technology for vacuum cleaners and floors, which is applied in the direction of vacuum cleaners, suction nozzles, household appliances, etc. It can solve the problem that coarse dirt particles do not reach the suction air flow, and achieve a good suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

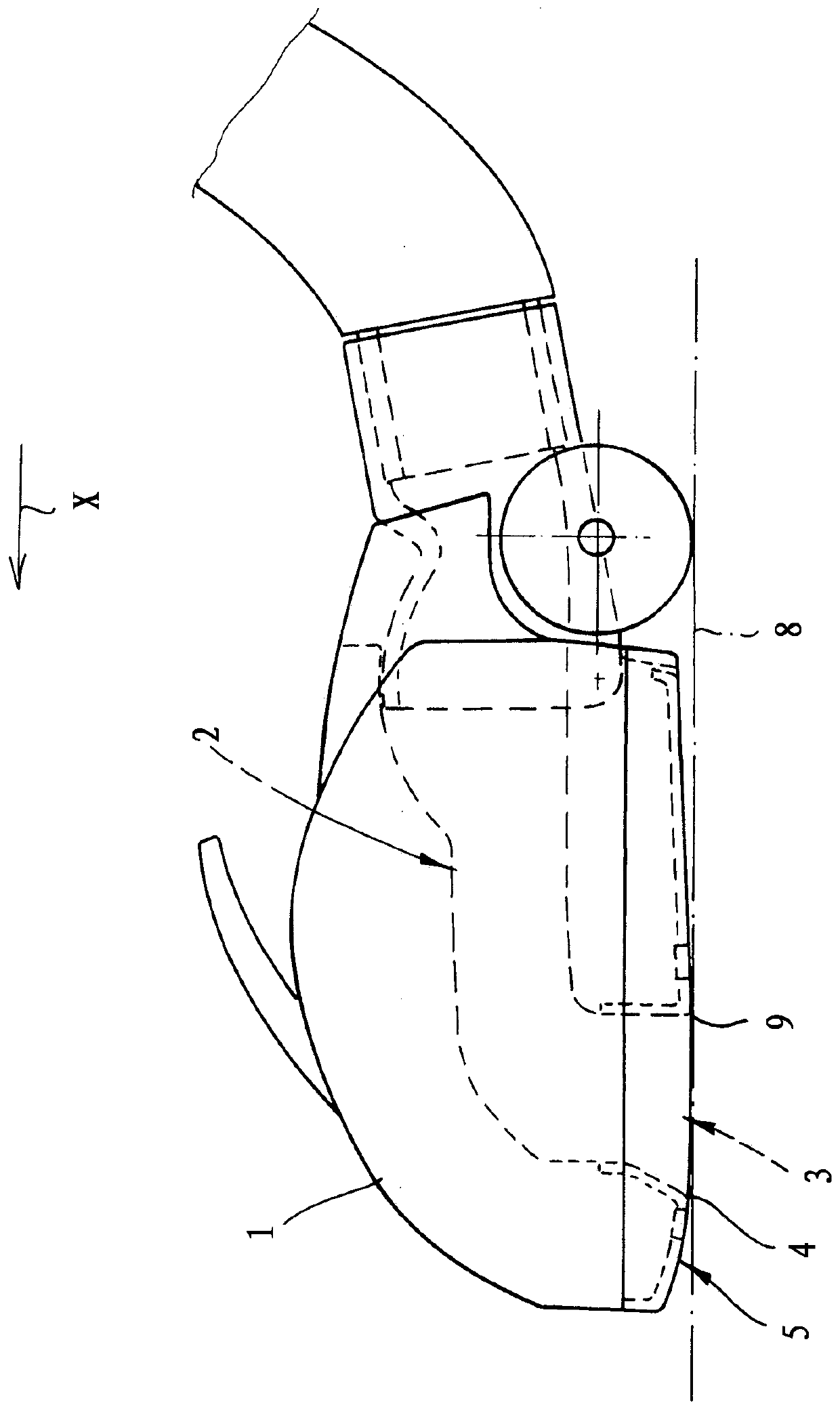

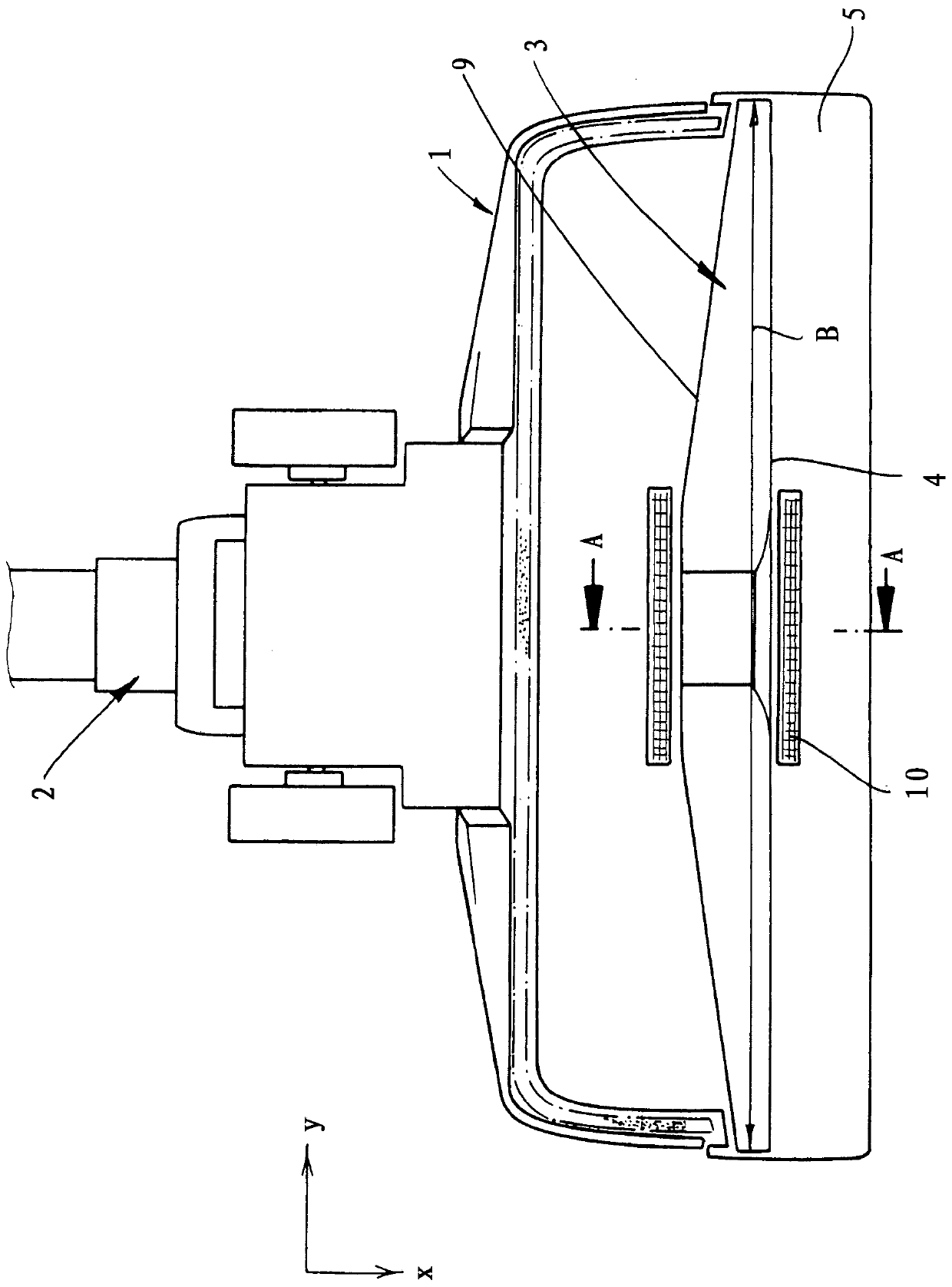

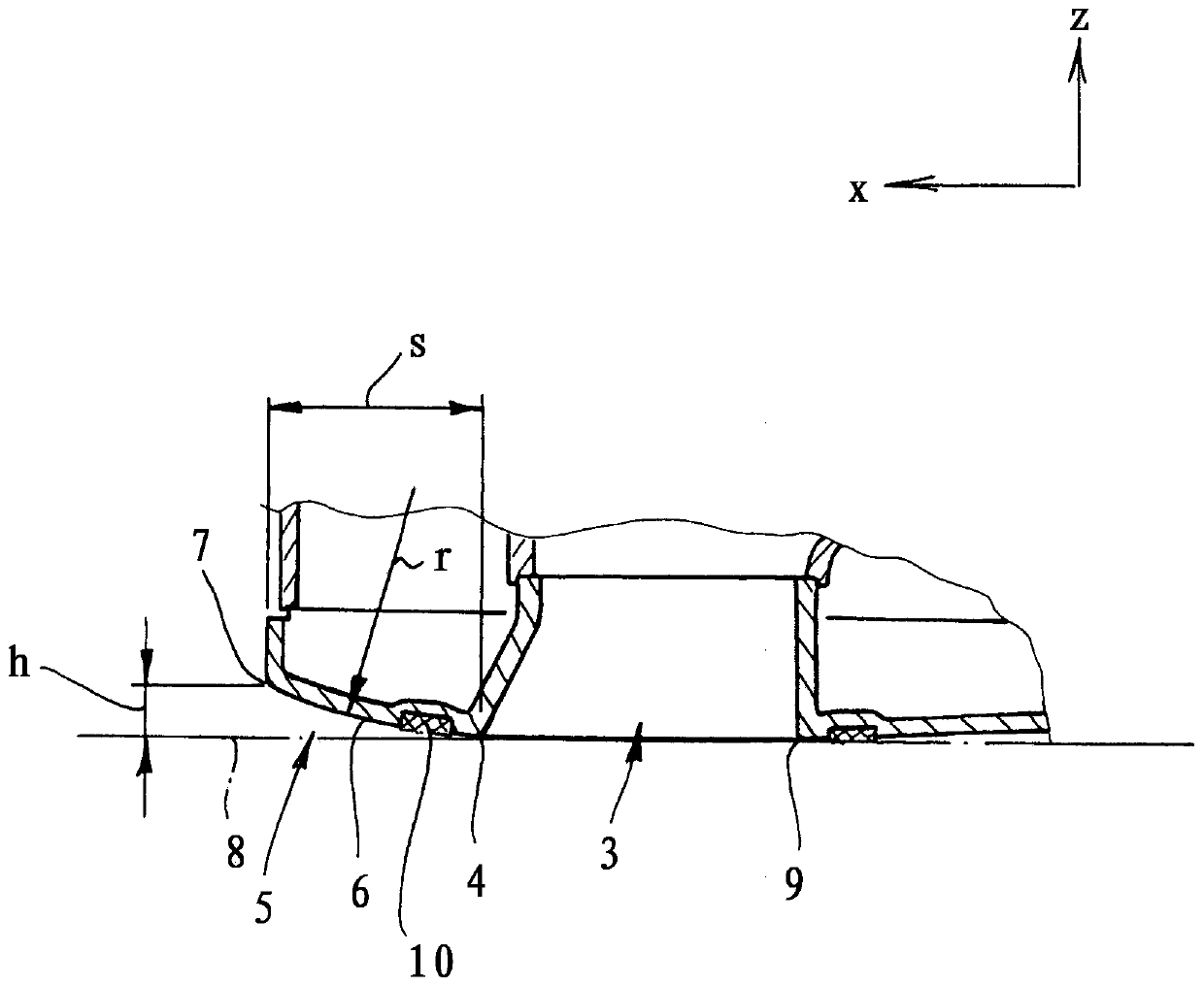

[0023] exist figure 1 and 2 The basic structure of the floor nozzle of the vacuum cleaner can be seen in : The floor nozzle of the vacuum cleaner has a housing 1 extending in the working direction x and in a transverse direction y perpendicular to the working direction and a Suction opening 3 on guide 2. The suction opening 3 extends across a width B in the transverse direction y and is delimited in the working direction x by a front suction opening edge 4 and a rear suction opening edge 9 .

[0024] According to the invention, a sliding surface 5 is provided in front of the front suction opening edge 4 which extends in the transverse direction y over at least 75% of the width B of the suction opening 3 . sliding surface 5 in Figure 3A In the longitudinal section shown, along the working direction x, there is a circular segment 6 whose radius of curvature r is between 40 mm and 80 mm. Along the working direction x, the sliding surface 5 extends over a length s of at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com