Overheating prevention method and system for cutting position of high-speed cutter grinding machine tool

A technology of tool grinding and preventive methods, which is applied in the directions of grinding machine tool components, grinding/polishing equipment, grinding/polishing safety devices, etc., which can solve the problem of damage to machine tool circuit pipelines, lack of cooling means for machine tools, and large safety hazards, etc. problem, to achieve the effect of improving the safe operation coefficient, improving safety and reliability, and cooling down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

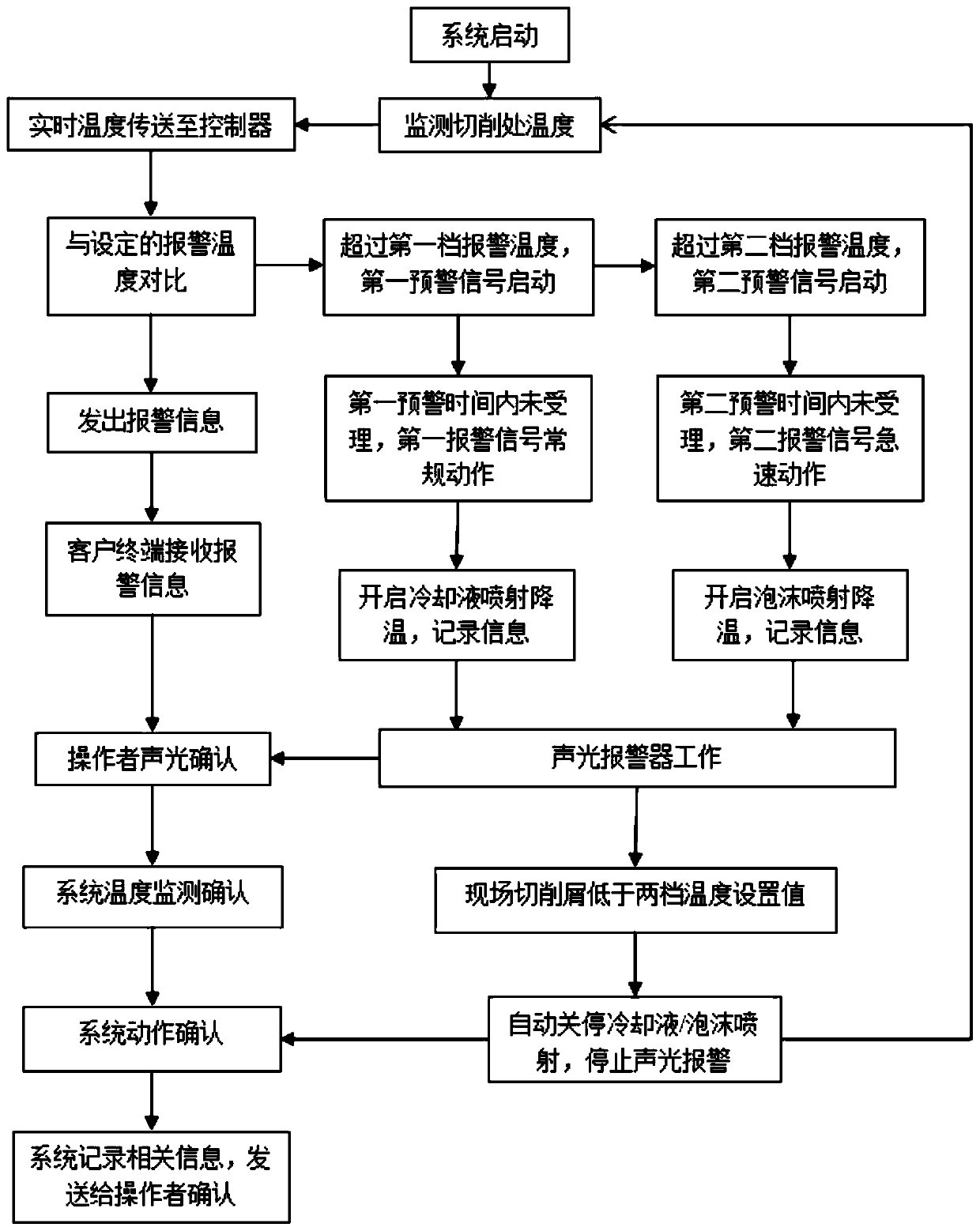

[0023] refer to figure 1 , a method for preventing overheating at the cutting place of a high-speed tool grinding machine tool of the present invention monitors the real-time temperature of the cutting place in real time, and compares the real-time temperature with at least two preset alarm temperatures; the real-time temperature is within the alarm temperature range According to the alarm temperature gear where the real-time temperature is located, the corresponding early warning information is issued, and the cooling process is carried out according to the early warning information. By monitoring the temperature of the cutting place in real time, when the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com