A resin raw material premixing device

A resin raw material and premixing technology, applied in the field of resin processing, can solve the problems of poor premixing effect, difficult control of resin mixing conditions, waste of manpower and material resources, etc., and achieve the effects of convenient addition, reduction of manpower loss, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

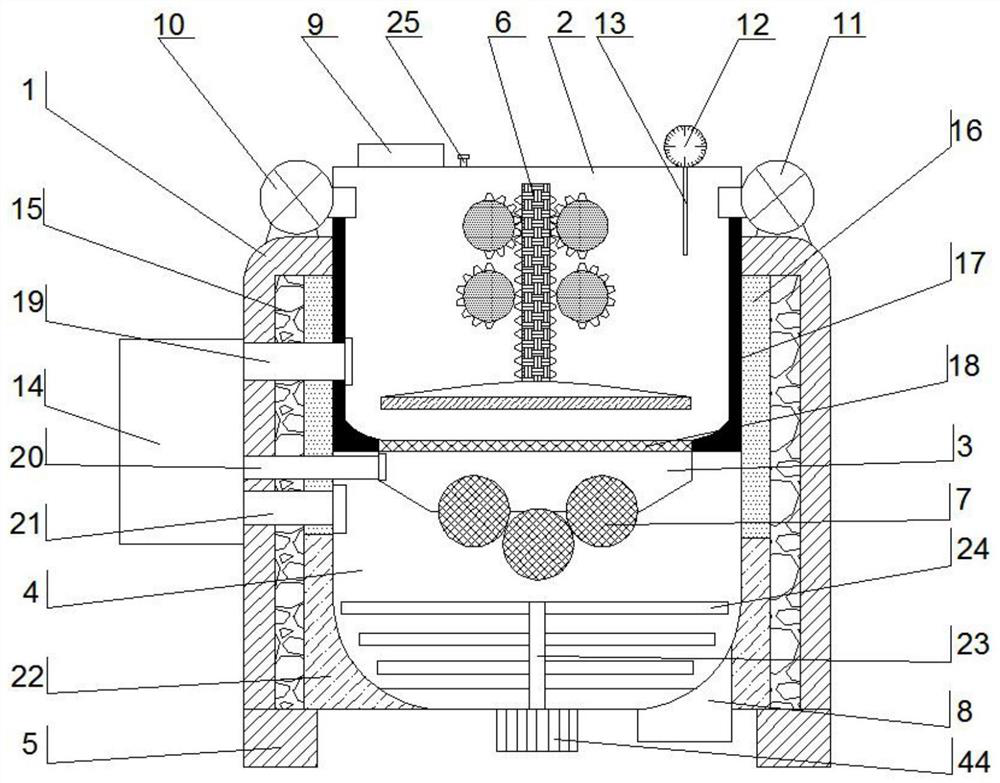

[0032] refer to figure 1 , Figure 5 with Figure 7As shown, a resin raw material premixing device includes a protective shell 1, a squeeze barrel 2 inside the protective shell 1, a crushing bucket 3 and a mixing barrel 4, and support legs 5 arranged in a four-corner array at the bottom of the protective shell 1. The pressure barrel 2, the crushing bucket 3 and the mixing barrel 4 are sequentially connected from bottom to top. The upper end of the extrusion barrel 2 extends to the outside of the protective shell 1. A material inlet 9 is provided on one side of the top of the extrusion barrel 2, and a material inlet 9 is provided on the other side. The barometer 12, the barometer 13 connected to the lower end of the barometer 12 extends to the inside of the extrusion barrel 2, and the two sides of the top of the protective shell 1 are respectively fixed with an air pump 10 and an air pump 11, and the air pump 10 and the air pump 11 are connected with The squeeze barrel 2 is i...

Embodiment 2

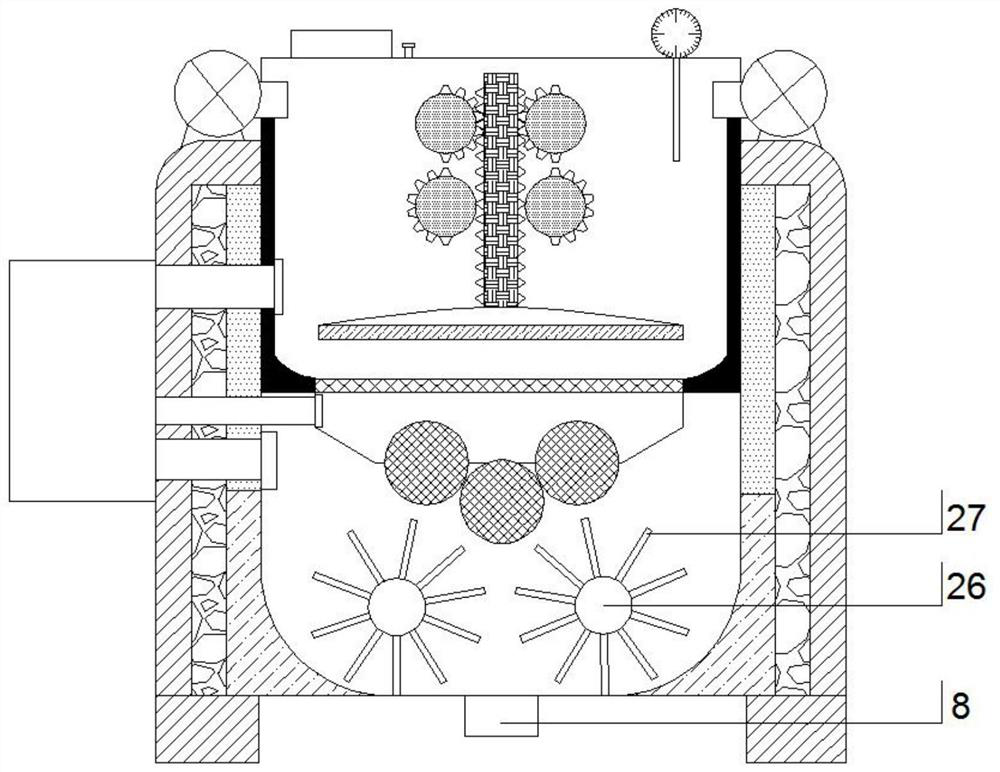

[0037] Such as figure 2 with Image 6 As shown, the present embodiment is basically the same as Embodiment 1. Preferably, the agitating mechanism includes agitating rollers 26 symmetrically arranged on both sides of the agitating barrel 4, and a plurality of second agitating blades are evenly arranged around the agitating roller 26. 27, the stirring roller 26 is rotationally connected with the inner wall of the mixing bucket 4 through the stirring roller shaft 43, and one end of the stirring roller shaft 43 extends through the protective shell 1 to the outside and is connected with the rotating belt 38, wherein one of the stirring roller shafts 43 is connected to the The output shaft of the third motor 42 is connected. Through the two stirring rollers 26, the surrounding materials are mixed more evenly, and at the same time, the materials are conveniently discharged.

Embodiment 3

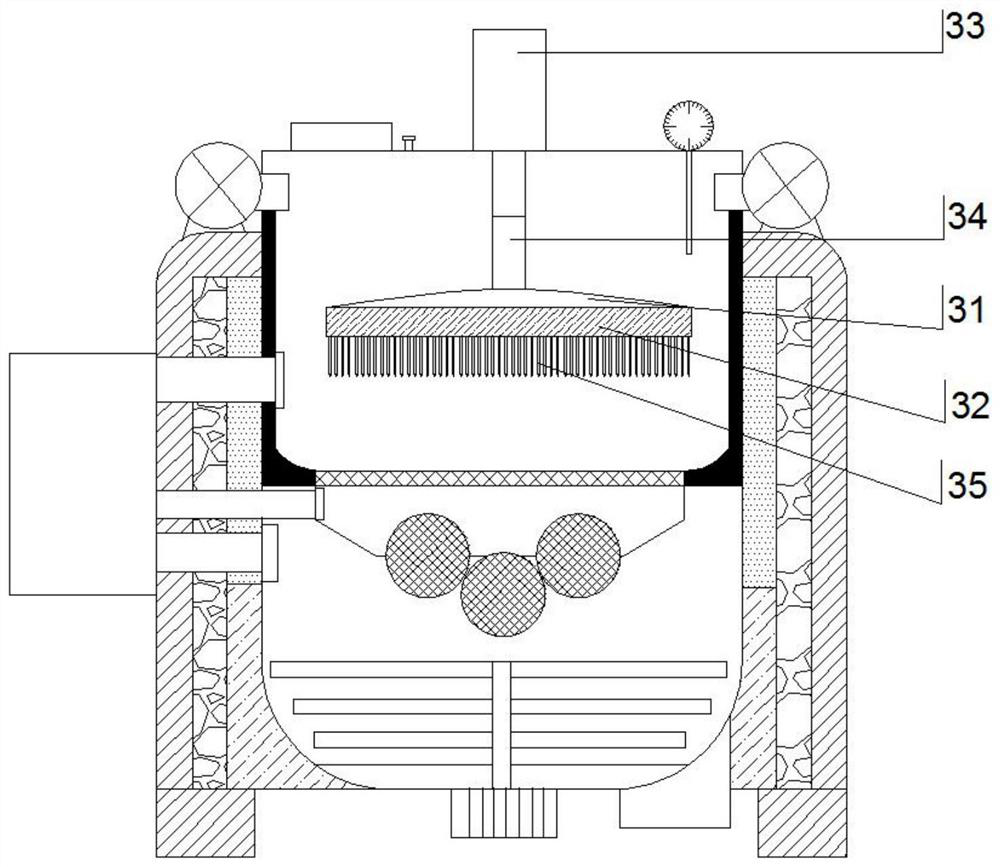

[0039] Such as image 3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the extrusion mechanism 6 includes a cylinder 33, a telescopic rod 34 and an extrusion plate 31. The telescopic rod 34 inside the press barrel 2 is connected, the extruding plate 31 is arranged at the lower end of the telescopic rod 34, and a layer of heating plate 32 is arranged at the lower end of the extruding plate 31, and a plurality of steel needles 35 are arranged at the bottom end of the heating plate 32. . The cylinder 33 is used as the power to improve the extrusion efficiency, and the setting of the steel needle 35 prevents the clogging of the leakage plate 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com