Automatic cover folding and carton sealing machine

An automatic, cover-sealing technology, applied in the directions of conveyor objects, packaging sealing/fastening, external support, etc., can solve the problems of no protection measures, economic losses, dumping, etc., to avoid economic losses, save working time, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

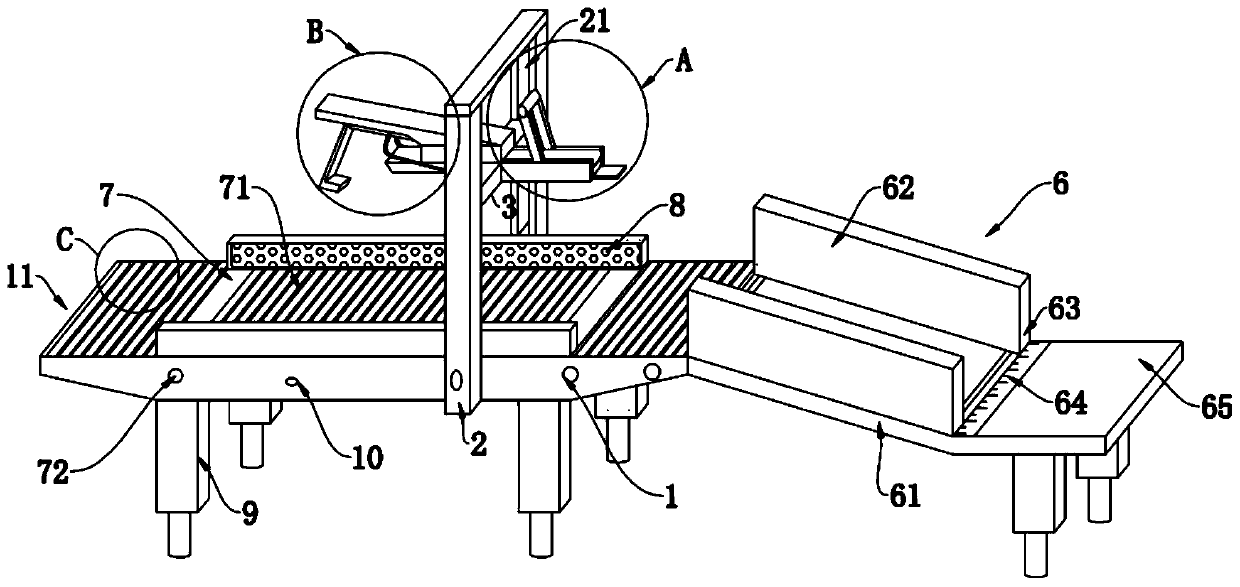

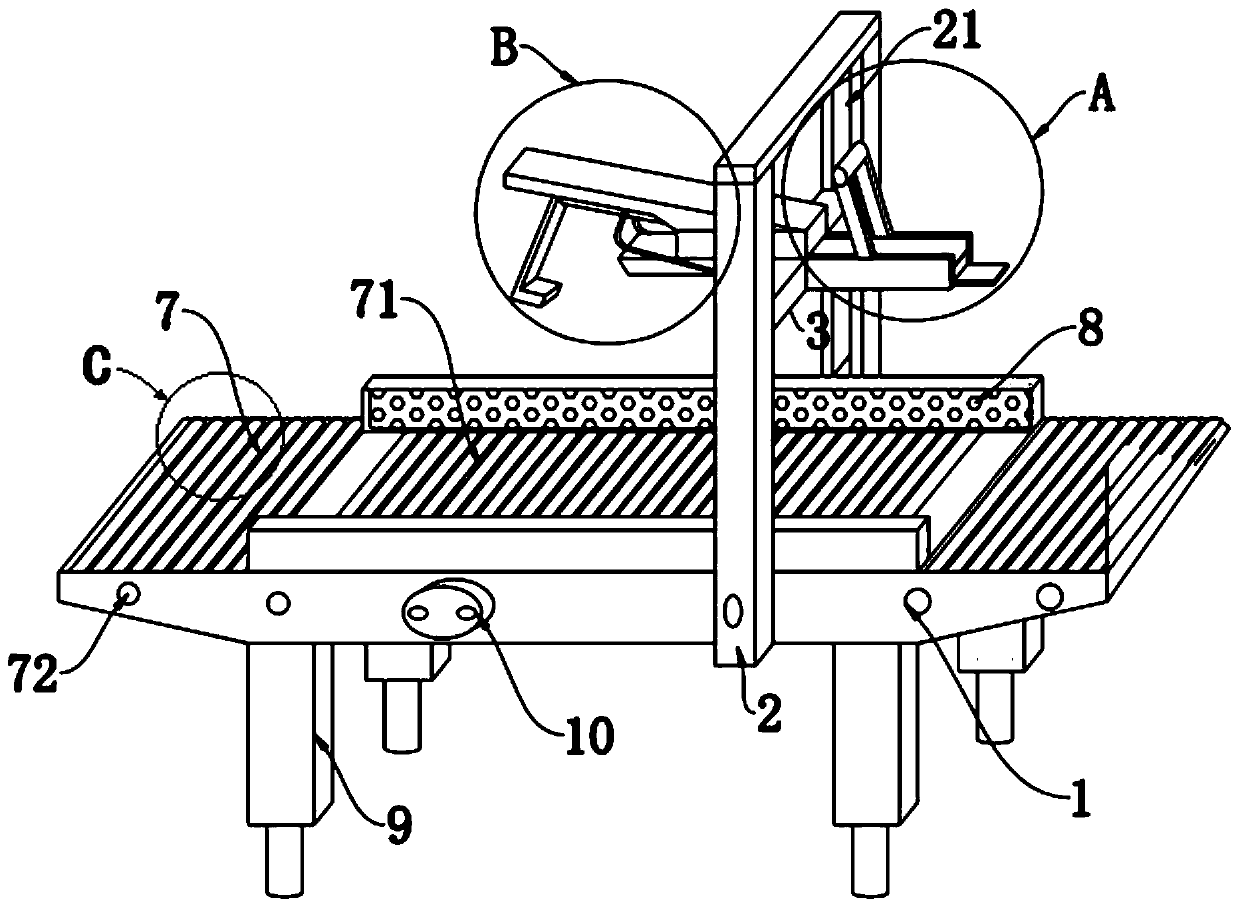

[0024] Such as figure 1 - Figure 5 As shown, an automatic folding and sealing machine includes a work panel 1 and a column 2 that is fixedly connected to both sides of the work panel 1 and extends toward the Y axis. The inner side of the column 2 is provided with a chute 21, and the chute The inside of 21 is equipped with a movable moving bar 3, and the middle part of the column 2 and the moving bar 3 are provided with a sealing mechanism 4 and an automatic folding mechanism 5 that is symmetrically arranged with the sealing mechanism 4. The upper end surface of the working panel 1 is provided with a conveying mechanism 6 closely connected to one side of the conveying platform 7 and the conveying platform 7 .

[0025] In this embodiment, the lid can be flipped and folded by the automatic lid folding mechanism 5 to close the carton lid, and the box can be sealed by the sealing mechanism 4, and then the automatic lid folding mechanism 5, the sealing mechanism 4 and the transpor...

Embodiment 2

[0037] Such as figure 1 - Figure 5 As shown, an automatic folding and sealing machine includes a work panel 1 and a column 2 that is fixedly connected to both sides of the work panel 1 and extends toward the Y axis. The inner side of the column 2 is provided with a chute 21, and the chute The inside of 21 is equipped with a movable moving bar 3, and the middle part of the column 2 and the moving bar 3 are provided with a sealing mechanism 4 and an automatic folding mechanism 5 that is symmetrically arranged with the sealing mechanism 4. The upper end surface of the working panel 1 is provided with a conveying mechanism 6 closely connected to one side of the conveying platform 7 and the conveying platform 7 .

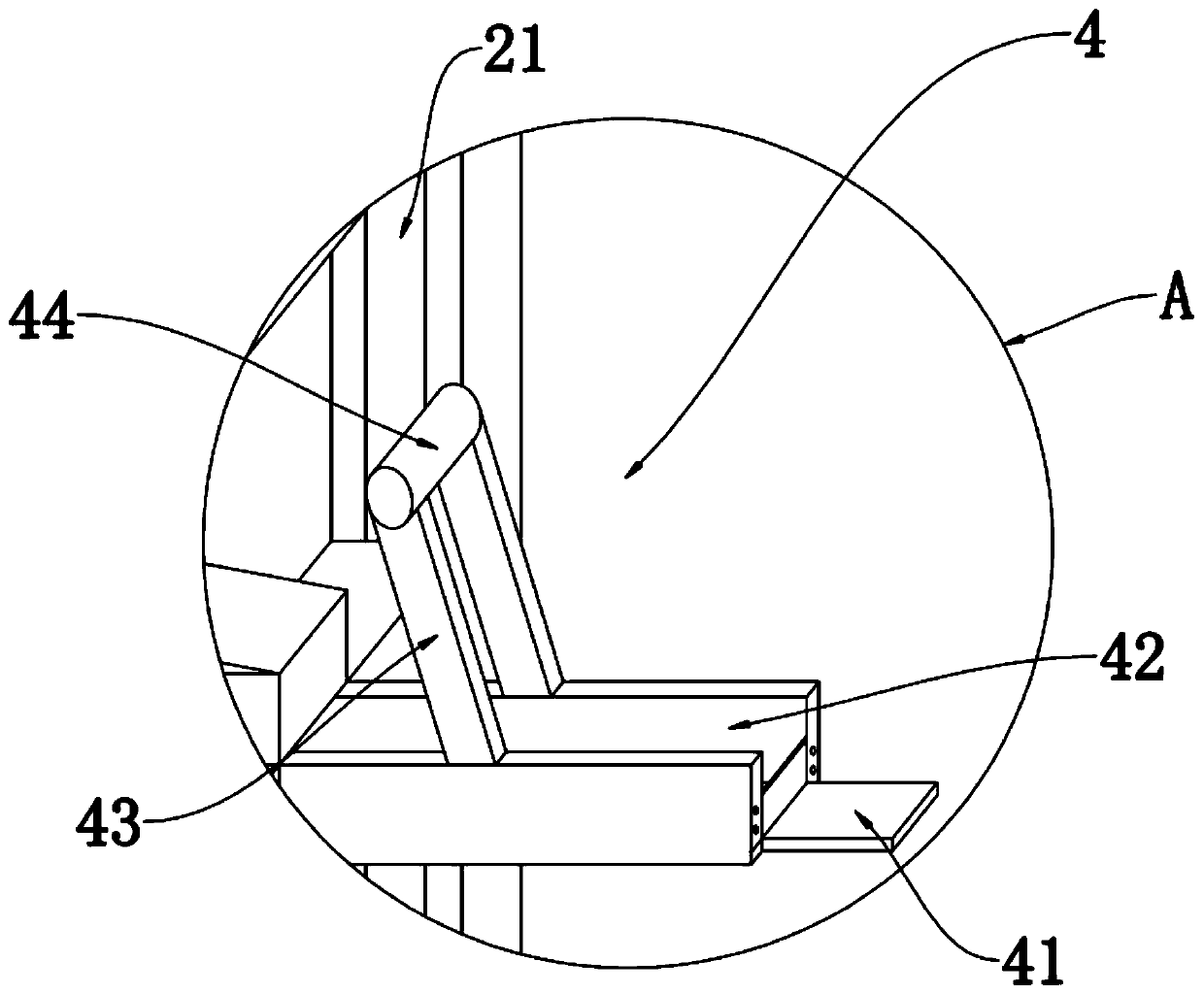

[0038] Such as figure 1 and figure 2 as well as image 3 As shown, the sealing mechanism 4 includes a sealing head 41 that is rotatably connected to a sealing cavity 42 and one side of the sealing cavity 42, and a support rod 43 is provided inside the both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com