Shock absorption node and building steel structure thereof

A node and node connection technology, applied in building components, building structures, buildings, etc., can solve problems such as inability to absorb shocks, and achieve the effect of avoiding displacement and ensuring support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

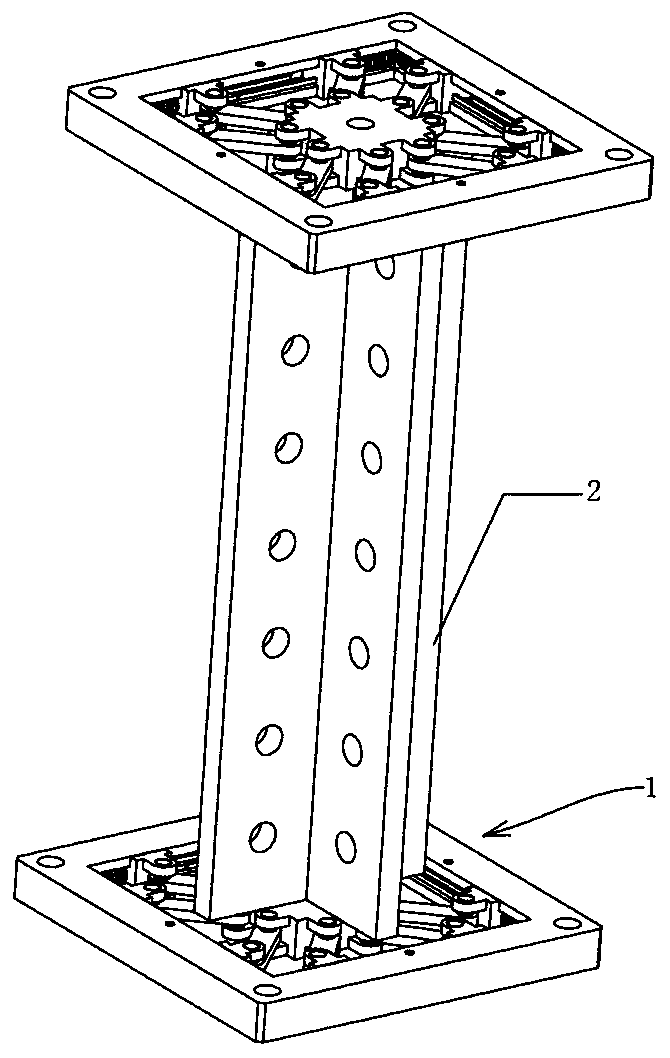

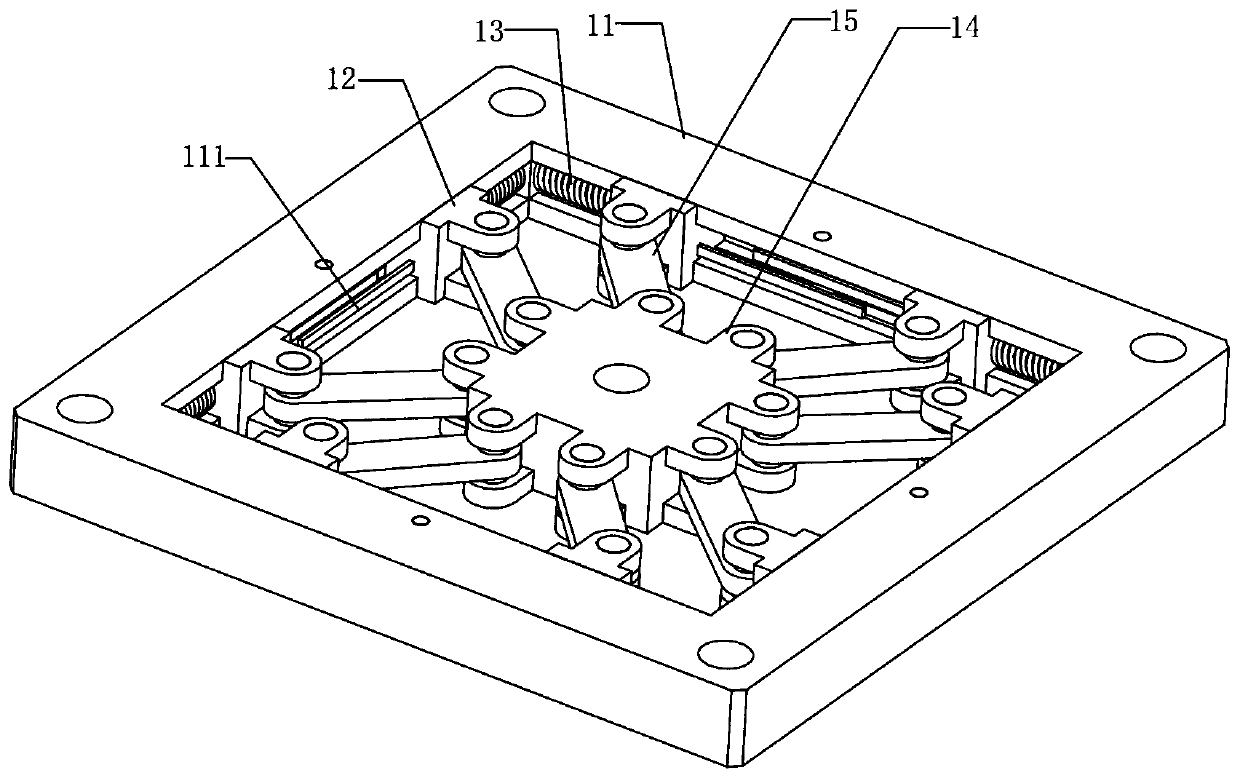

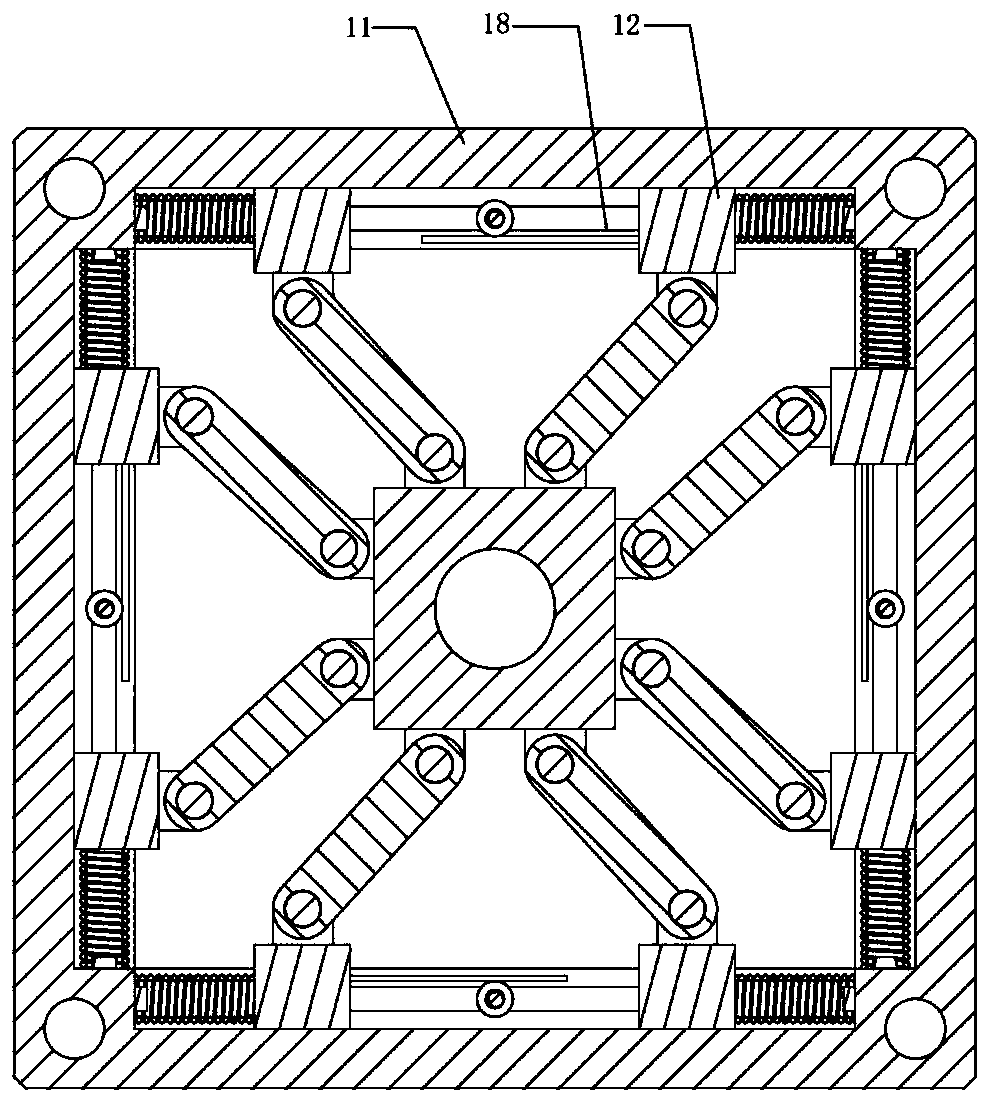

[0021] see Figure 1 to Figure 5 , the present invention provides a technical solution:

[0022] A shock-absorbing node, including a buffer base 1 and a node connecting frame 2, wherein:

[0023] The two buffer bases 1 are oppositely arranged, the node connecting frame 2 is arranged between the two buffer bases 1, and the middle plate 14 in the buffer base 1 is fixedly connected with the node connecting frame 2 by bolts, thus realizing the fixing of the node connecting frame 2;

[0024] The buffer base 1 includes a support frame 11, a slider 12, a spring 13, an intermediate plate 14, a connecting rod 15, a screw rod 16, a threaded sleeve 17 and a friction rod 18. The four sides inside the support frame 11 are respectively provided with guide rails 111, Two slide blocks 12 are movably installed in each guide rail 111, and a spring 13 is arranged between the slide block 12 and the side of the guide rail 111, wherein the spring 13 is positioned in the guide rail 111, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com