Attitude control engine thrust measuring device

A measurement device and engine technology, which is applied in the measurement device, jet engine test, gas turbine engine test, etc., can solve the problems of low measurement accuracy, large size, sensor damage, etc., achieve high calibration accuracy, improve force value transmission accuracy, The effect of increasing the force value transfer ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

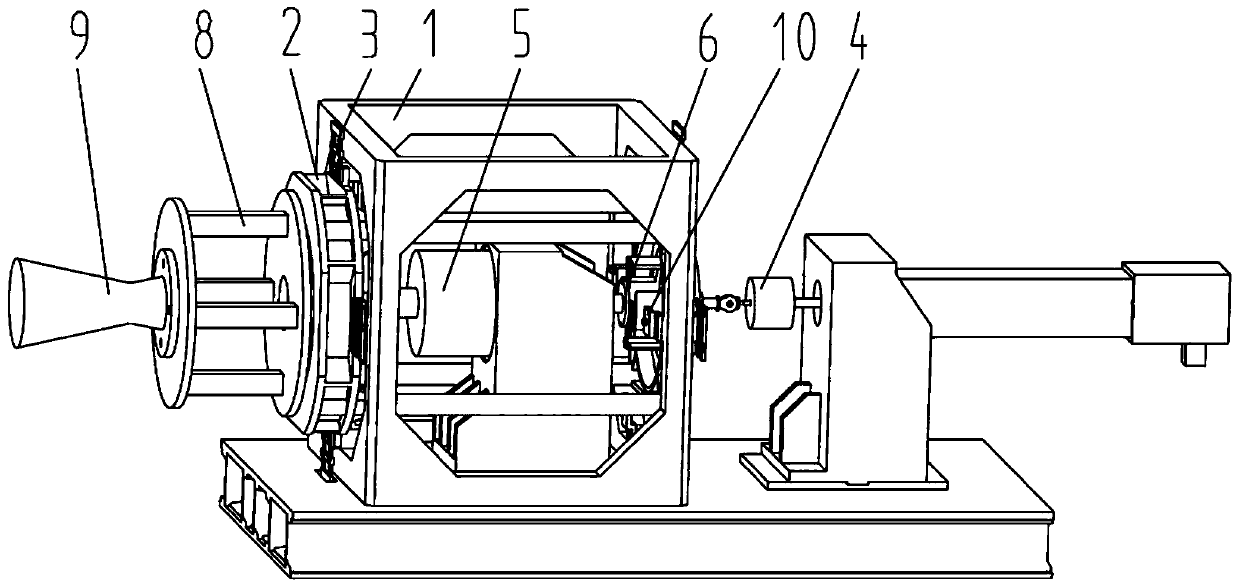

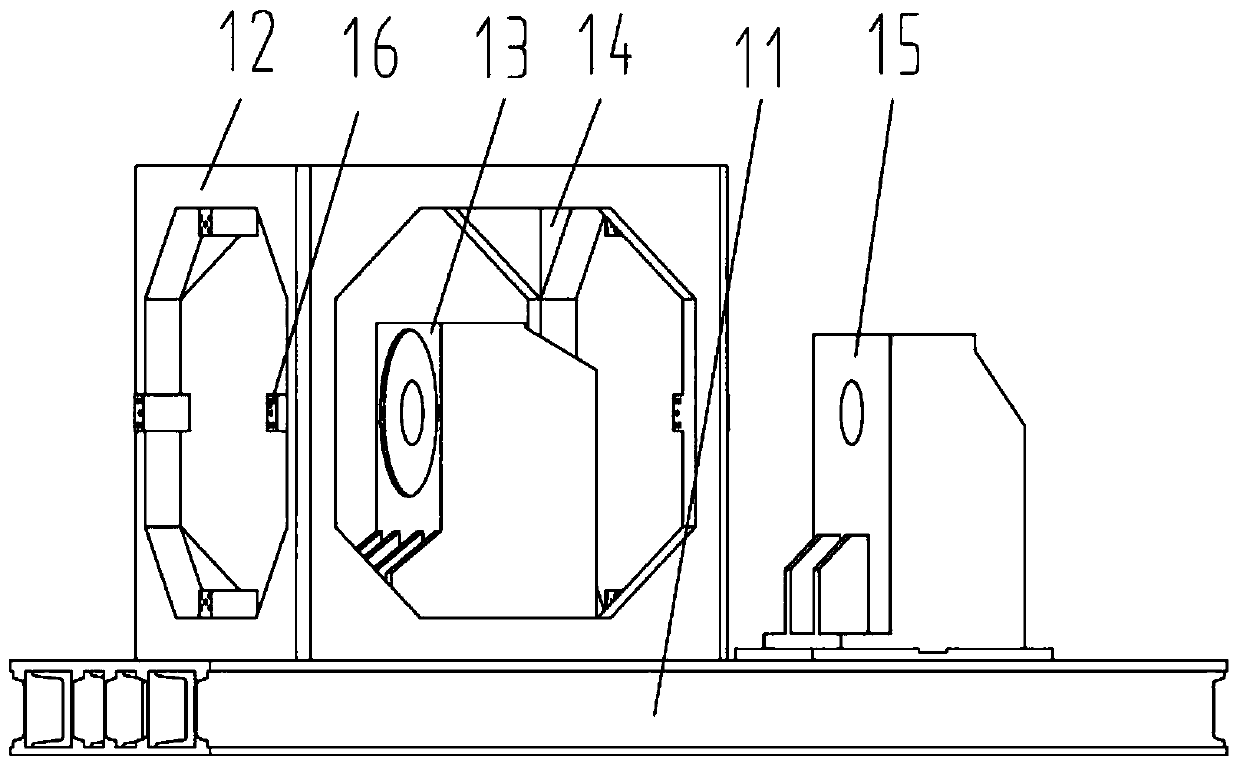

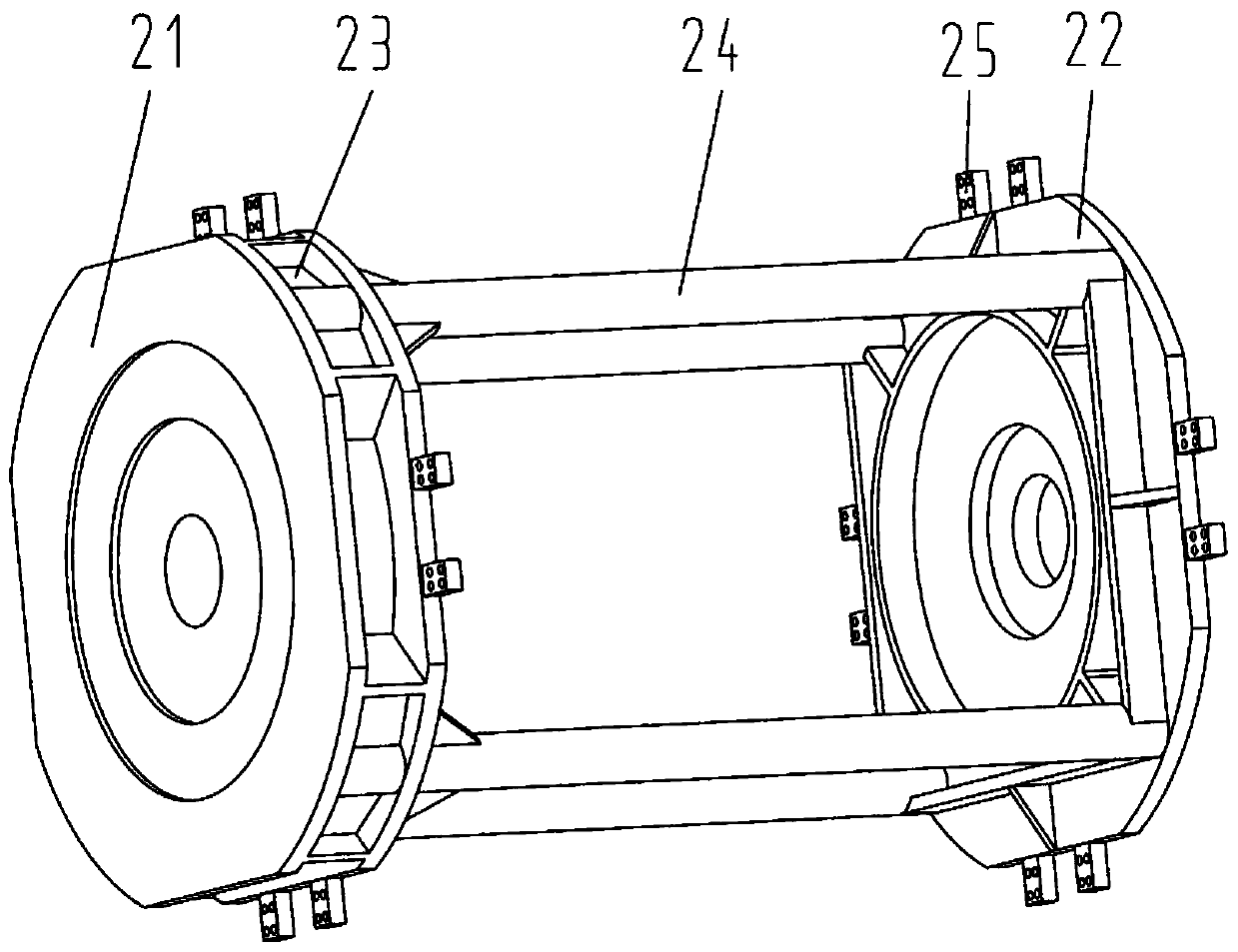

[0033] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] In order to realize the thrust measurement in the ground and high-altitude simulation tests of the 20kN level high-pressure attitude control engine, the invention provides a thrust measurement device for the attitude control engine. The measuring device adopts a one-point load-bearing structure with a single sensor to measure the thrust. The connection between the moving frame and the fixed frame adopts the front and rear mountain-shaped spring sheet structure. It adopts an automatic thrust in-situ calibration system composed of a standard force sensor and an electric cylinder. Afterburner calibration, the transmission path of the calibration force value is consistent with the test conditions. Through in-situ calibration, the influence of propellant supply pipelines, cooling pipelines, and measurement cables on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com