High-speed bearing retainer with reinforcing ribs

A technology for high-speed bearings and cages, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., and can solve problems such as cage wear, high speed requirements, and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

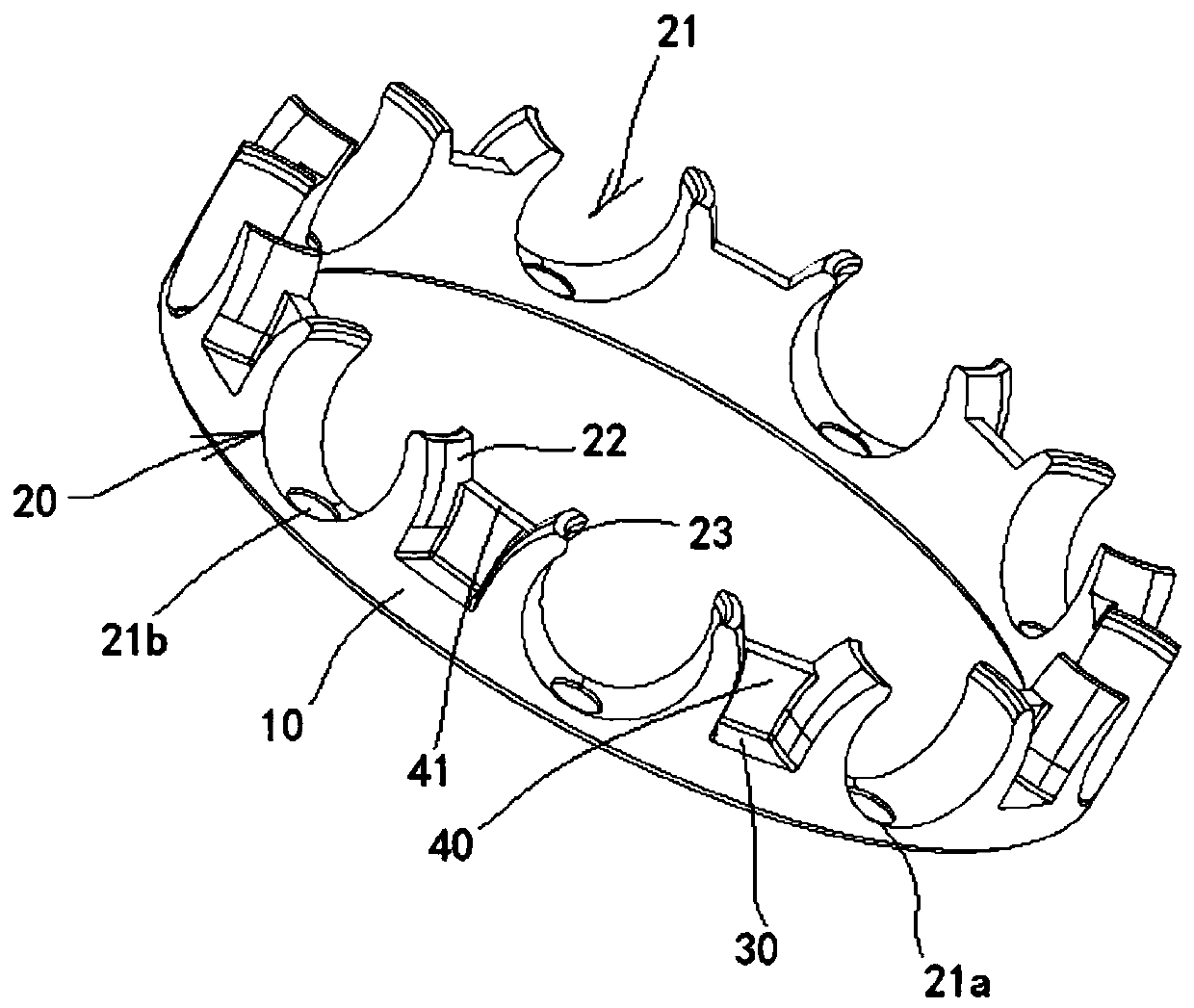

[0014] see figure 1 , a height bearing cage with reinforcing ribs shown in the figure includes a ring frame body 10, and a number of cage ball pockets 20 are arranged at intervals on one end surface of the ring frame body 10, and each cage ball pocket 20 is provided with a ball pocket hole 21 .

[0015] The present invention is characterized in that: a reinforcing rib 40 is arranged on the cage shoulder 30 between two adjacent ball pockets 20, the reinforcing rib 40 is arranged on the inner side of the cage shoulder 30, and the two sides of the reinforcing rib 40 are respectively connected with The catch outer spherical surfaces 22 of two adjacent cage ball pockets 20 are connected as a whole, the upper plane 41 of the reinforcing rib 40 is lower than the upper surface 23 of the cage ball pocket 20, and the thickness of the reinforcing rib 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com