Electric welding mask with dust removal function

A mask and functional technology, which is applied in the field of electric welding masks with dust removal function, can solve the problems of stuffy heat, affect the work efficiency of workers, and poor experience of workers, and achieve the effect of improving permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

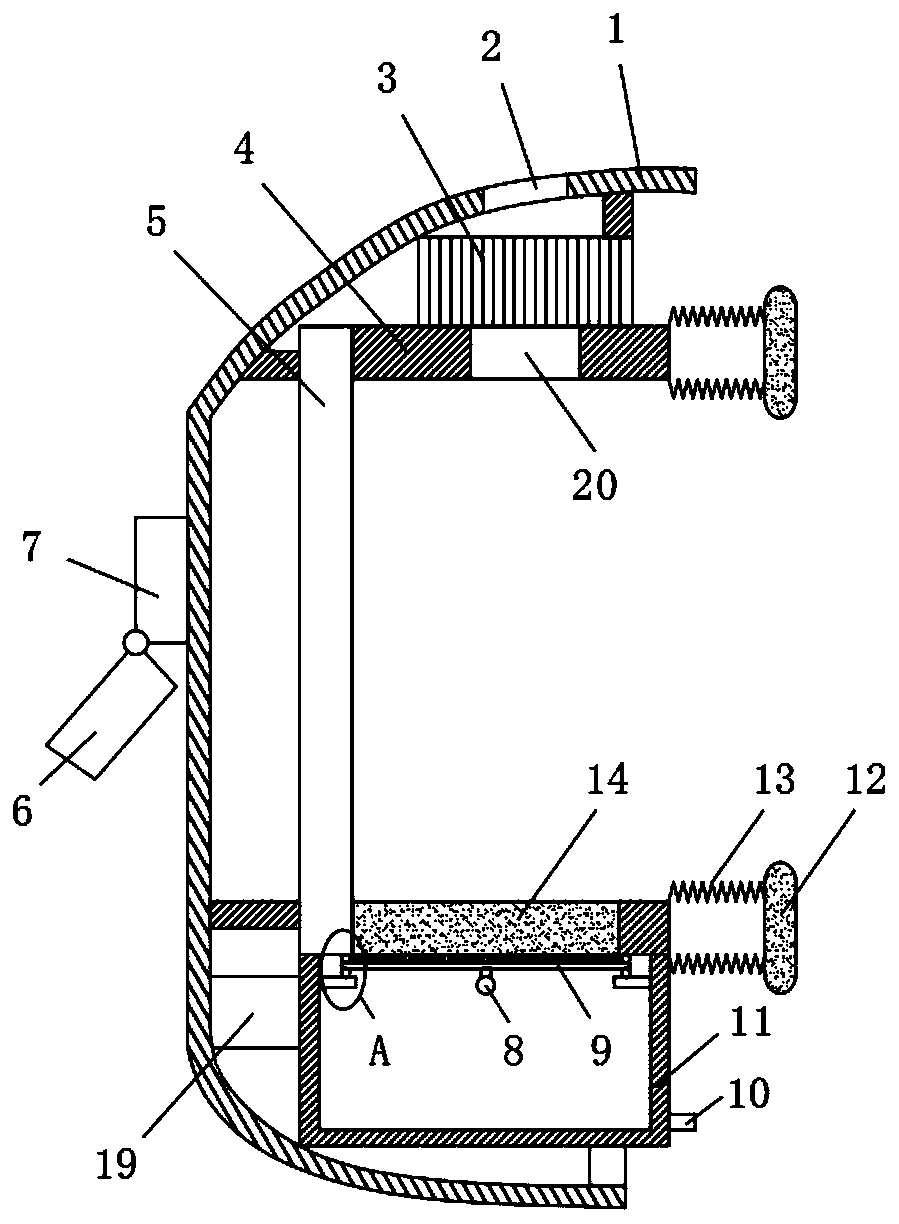

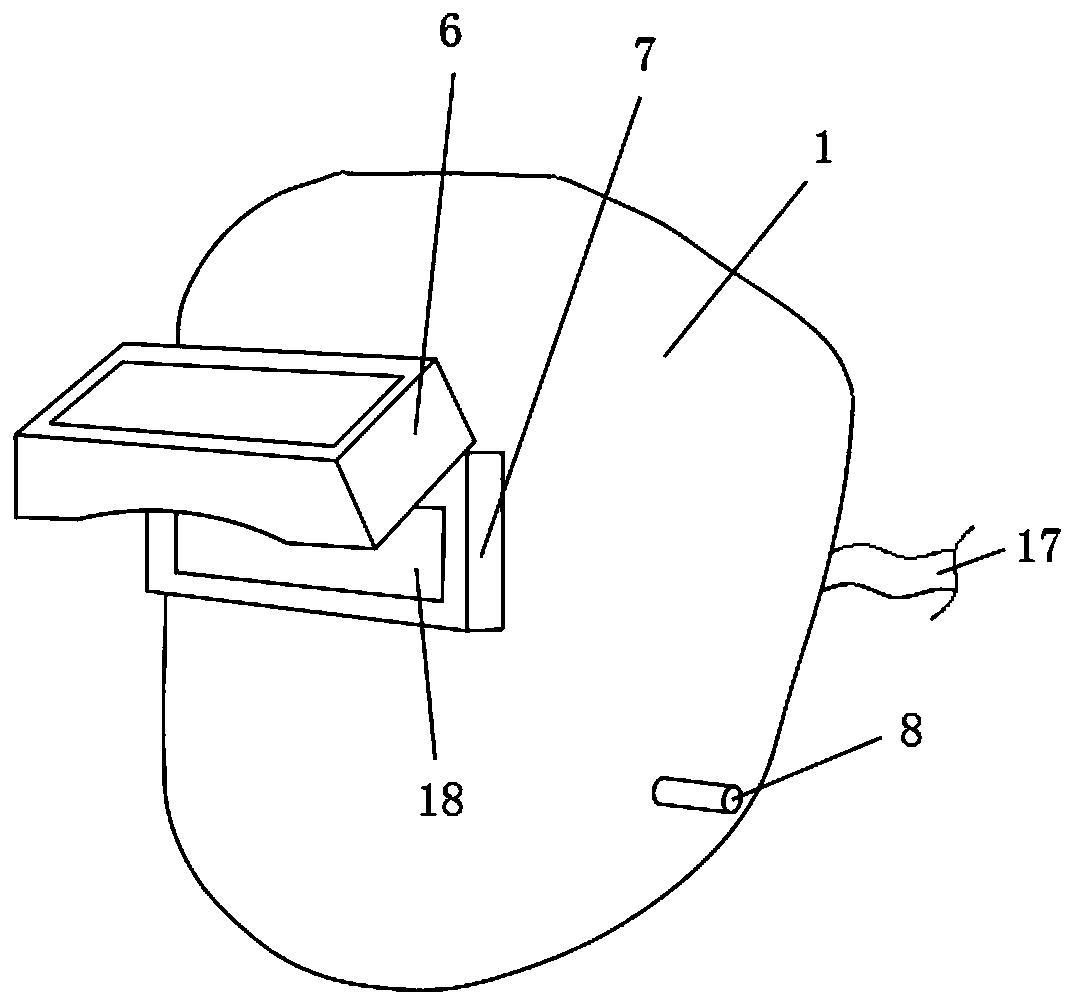

[0023] see Figure 1~4 , in the embodiment of the present invention, a kind of electric welding mask with dust removal function, comprises shell 1 and the see-through window 7 that is arranged on shell 1, see-through window 7 is fixedly installed with see-through mirror 18, and described shell 1 is provided with dust removal assembly , the dust removal assembly includes a sealing cover 4 and a dust collection box 11, a transparent plate 5 is fixedly installed on one side of the sealing cover 4, and a sealing ring 12 is connected to the other side of the sealing cover 4 through a telescopic tube 13, and the sealing cover The bottom of 4 is provided with dust removal net 14, and described dust collecting box 11 is fixedly installed below sealing cover 4 and dust collecting box 11 communicates with atmosphere through air inlet pipe 19, and the top of sealing cover 4 is provided with opening 20, and sealing cover 4 A small exhaust fan 3 is fixedly installed at the opening 20 on th...

Embodiment 2

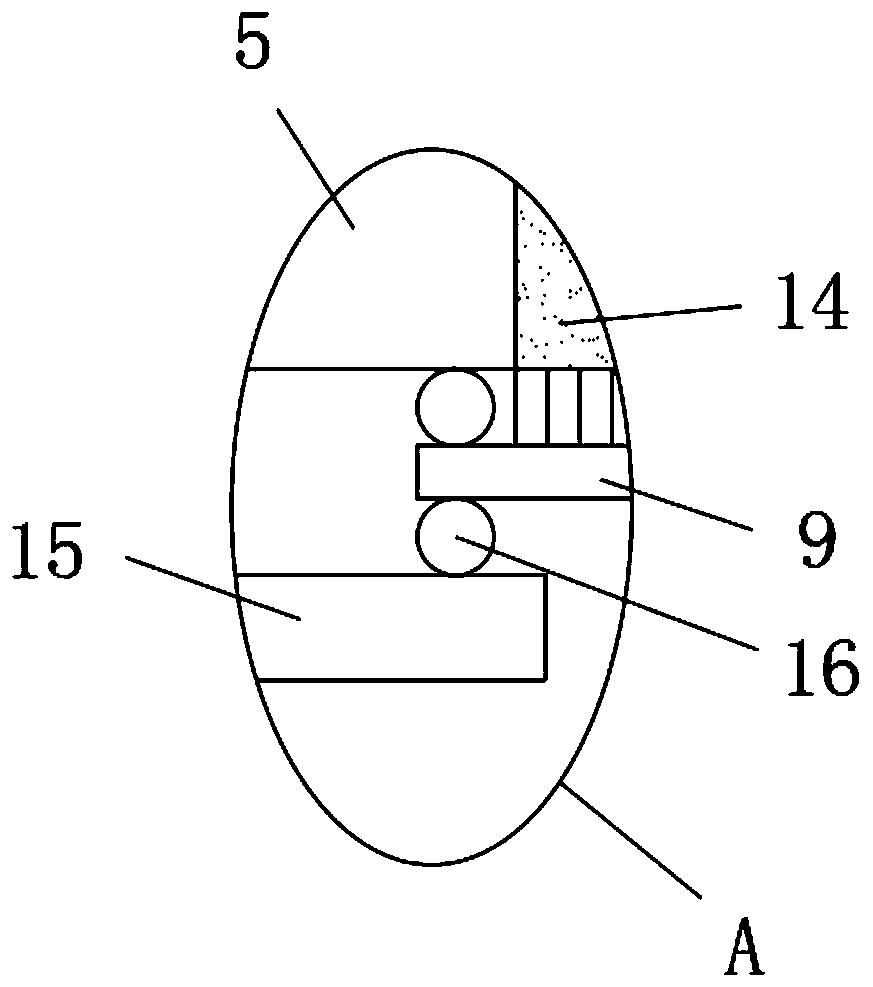

[0031] This embodiment is a further improvement on the basis of embodiment 1. Compared with embodiment 1, the main difference is that baffles 15 are fixedly installed on the side walls of both sides of the dust collection box 11, and the baffles 15 There is a brush 9 between the dust removal net 14 and the brush 9 is rolled on the baffle 15 by the ball 16. The middle part of the brush 9 is fixedly equipped with a pull rod 8, and the pull rod 8 is slidingly clamped on the side wall of the dust box 11. and the pull rod 8 extends through the shell 1 to the outside of the shell 1, the pull rod 8 is elastically connected to the inner wall of the dust box 11 through the spring 21, and the baffles 15 are fixedly installed on the two side walls of the dust box 11 And on the baffle plate 15, a hairbrush 9 is rolled, and the dust attached to the dust removal net 14 can be cleaned by the hairbrush 9 by manually pulling the pull bar 8, so as to improve the permeability of the dust removal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com