A kind of artificial nerve graft and its preparation method

A technology for artificial nerves and grafts, applied in the field of nerve grafts, which can solve problems such as limiting accurate matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of artificial neurotransplate of the present invention includes:

[0027] (1) Preparation of polyester solution

[0028] Take a certain amount of degradable polyester, dissolved in an organic solvent, stirred 1 to 2 anime, fully dissolved.

[0029] Degrading polyester includes polylactic acid, polylactic acid-trimethylene carbonate (P (La-TMC)), polyvi acid, poly (D, L-lactic acid-CO-glycolic acid), poly (D, L-lactic acid) -CO-caprolactone), poly (d, L-lactic acid-CO-trimethylene carbonate), etc.

[0030] Organic solvents include 2,2,2-trifluoroethanol, hexafluoropropyl alcohol, chloroform, dichloromethane, and the like.

[0031] (2) Electrostatic spinning processing neural sleeve

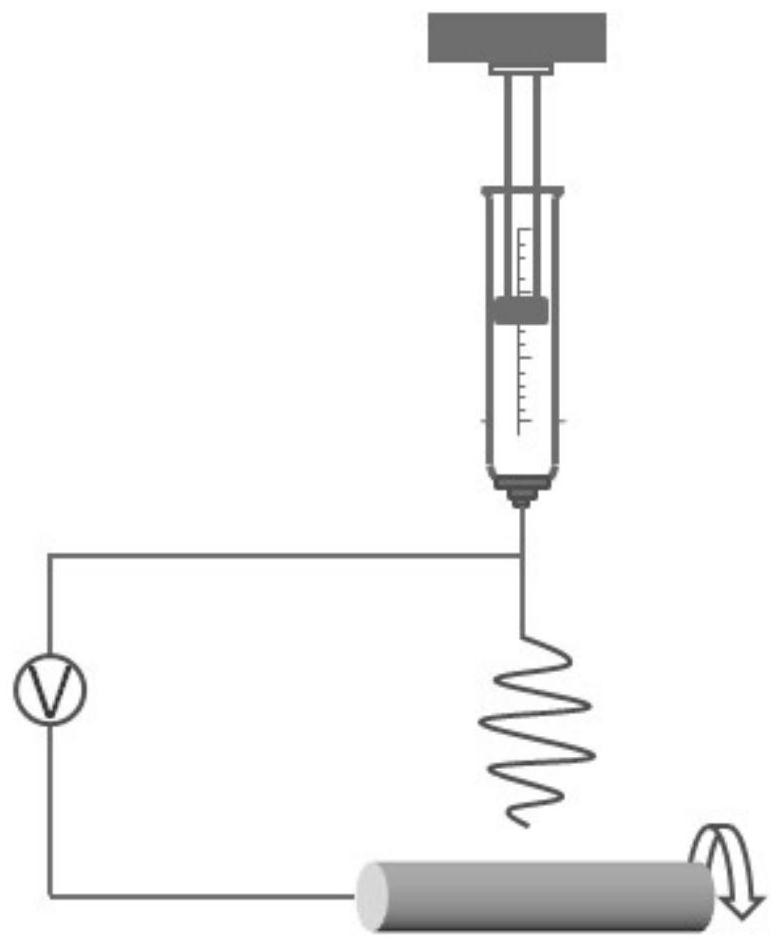

[0032] according to figure 1 The above polyester solution is transferred to the syringe and placed on the injection pump to perform electrostatic spinning processing.

[0033] Among them, the injection rate of the solution is 0.5 to 4 ml / h; the injection needle injector ...

Embodiment example 1

[0052] Preparation of the case of a microchannel decellular matrix (sour source, PDNM) neurotransplate

[0053] P (LA-TMC) 70 / 30 is dissolved in 2,2,2-trifluoroethanol in the above method, and the concentration of 15% w / v; according to the above steps 1 to 3, it is prepared for electrospinning. A neural sleeve of 2 mm inner diameter and about 0.25 mm thick.

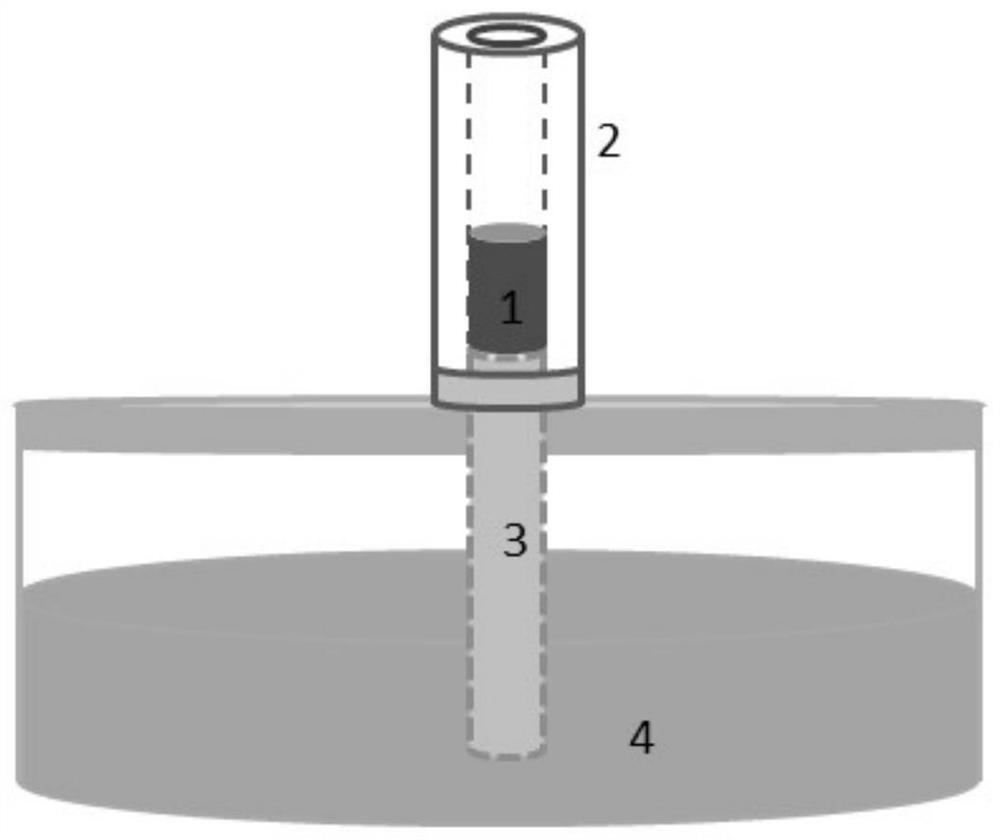

[0054] Pork source ambient decellular matrix (PDNM) was digested, pH, solubized by digestion, tuning pH, sol (La-TMC) in the above steps 6 to 9 according to the above steps 4 to 5; PDNM sol The 70 / 30 nerve sleeve, and the liquid nitrogen is used as a cold source to oriene freeze crystals, and the artificial nerve plant is finally foundated at -20 ° C.

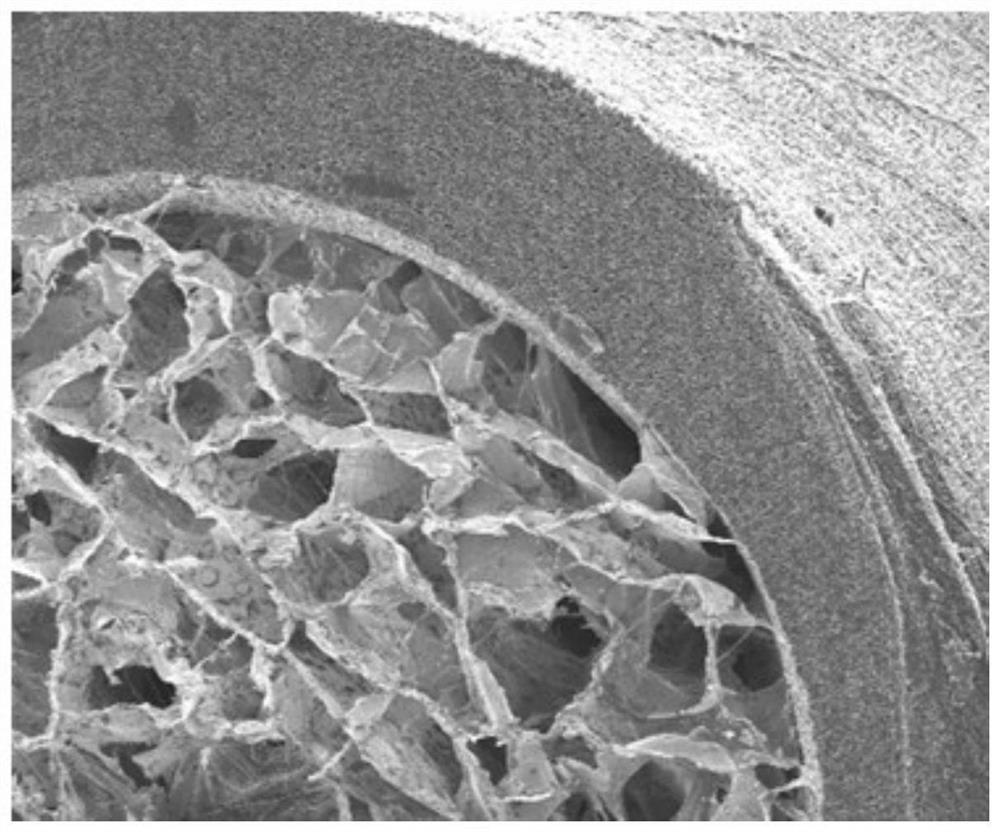

[0055] Its scanning electron microscope picture image 3 The neurotrophic is composed of two parts, including the inner layer such as Figure 4 As shown, a decellular matrix having a directional microchannel having a diameter of 20-100 μm, an outer layer such as Figure 5 As sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com