Combined type weak-torsion continuous mechanical arm connecting joint

A mechanical arm and continuous technology, applied in the field of robotics, can solve problems such as poor carrying capacity, high replacement cost, and inability to achieve effective control of torsion, achieving the effect of reducing replacement cost and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with embodiment.

[0024] The invention provides a combined weak torsion continuous mechanical arm connecting joint, which not only realizes combined installation, but also realizes weak torsion universal rotation.

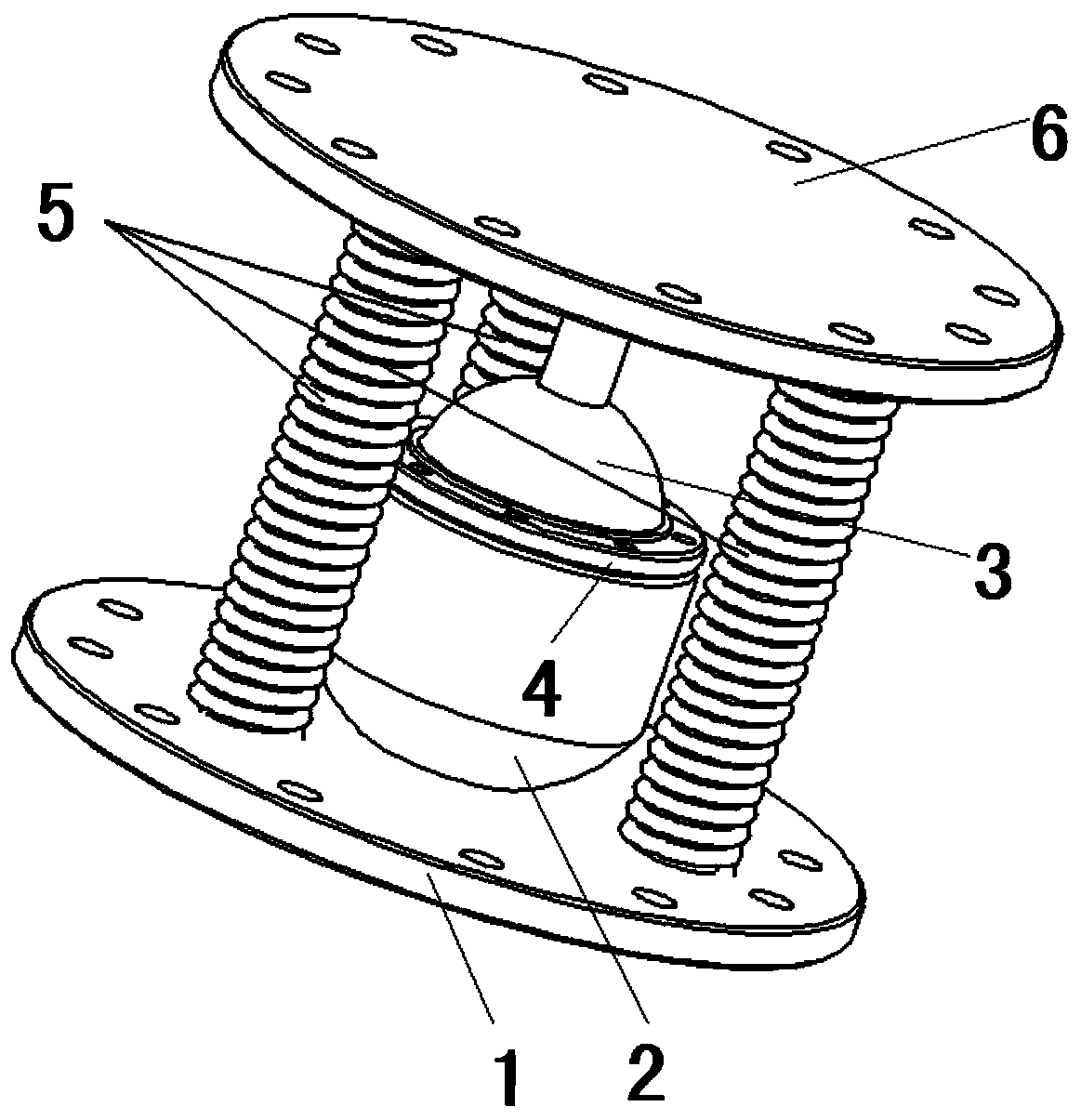

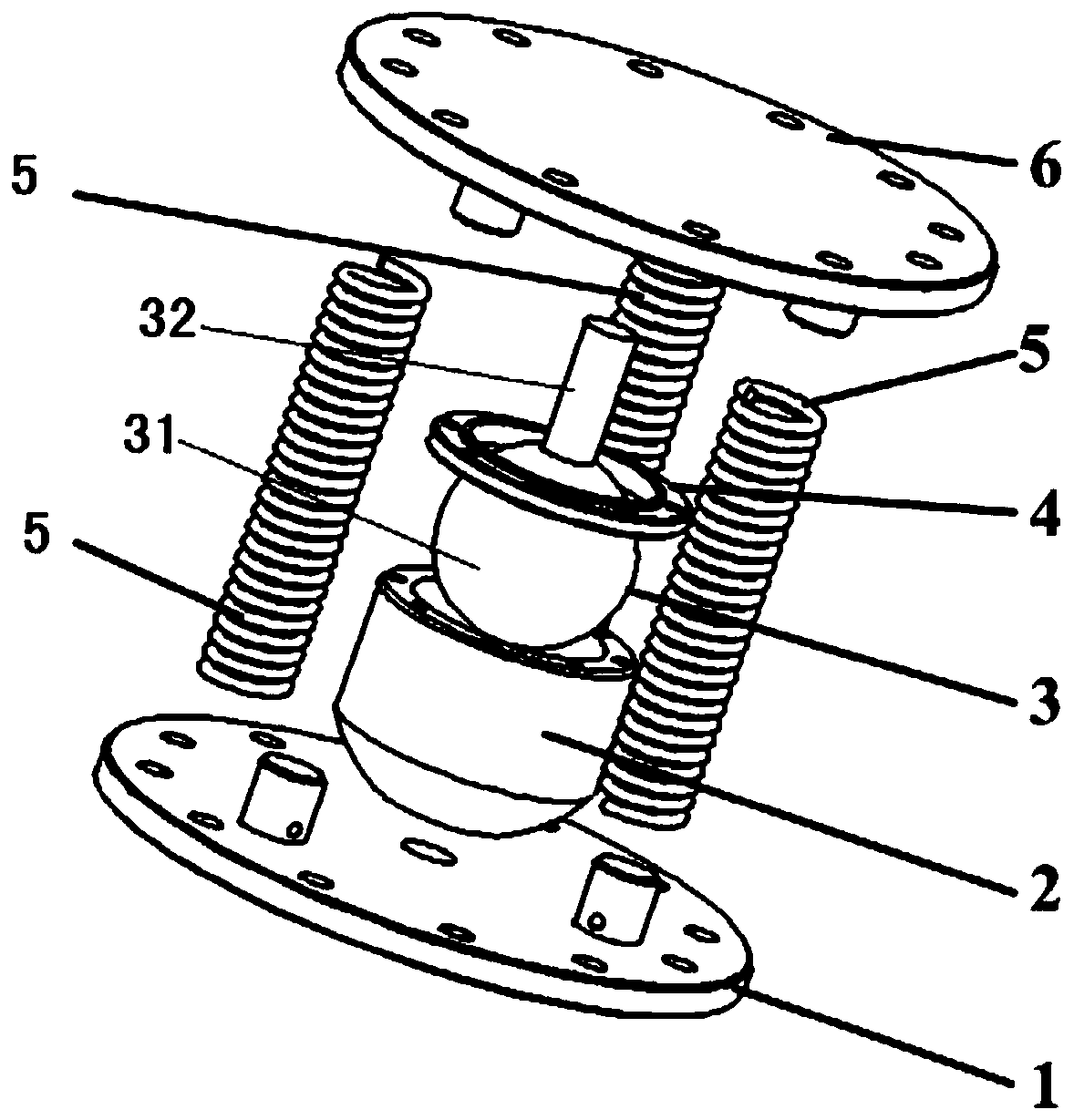

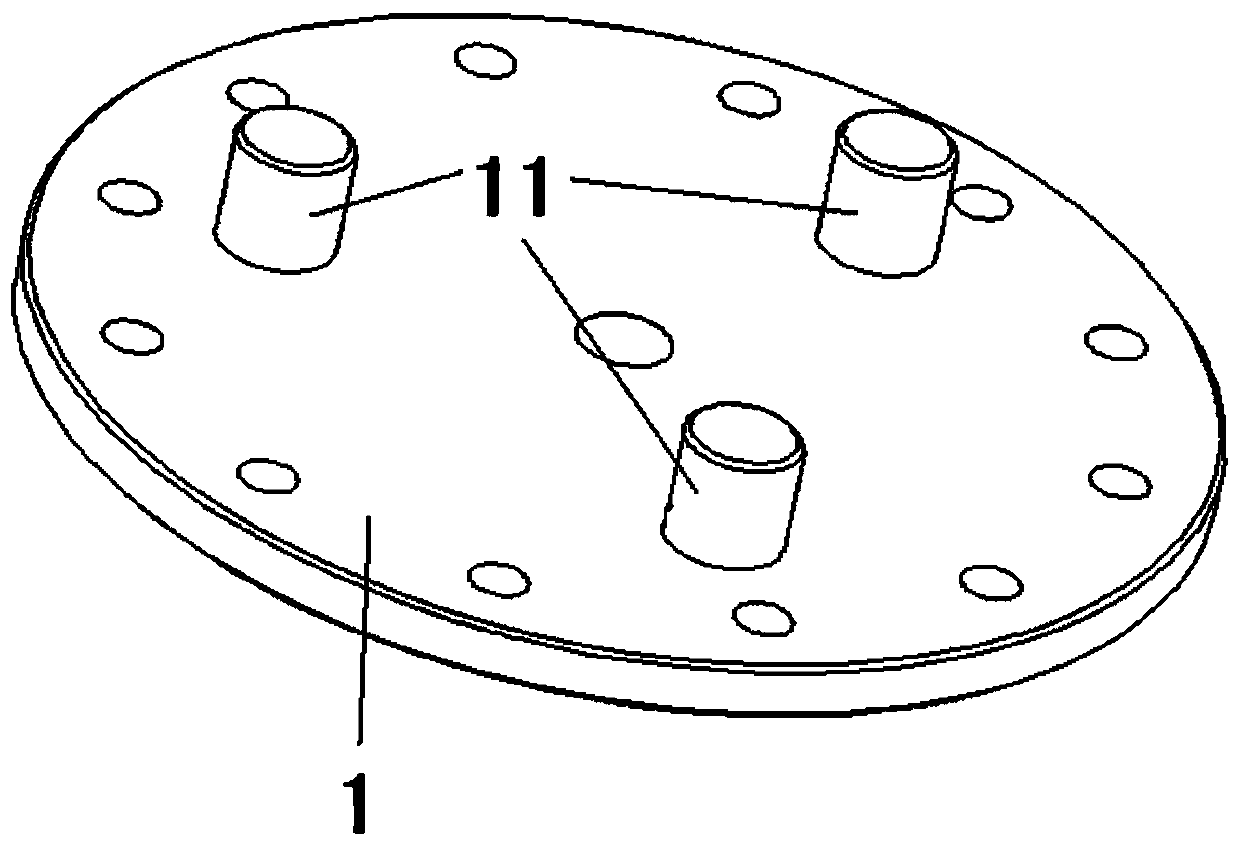

[0025] Such as figure 1 , figure 2 As shown, the connecting joint includes a ball socket base flange 1, a ball socket 2, a rotating ball 3, a rotating ball fixing cover 4, three torsion springs 5 and a rotating ball base flange 6; wherein, the ball socket base flange 1 is A circular plate-shaped structure placed horizontally; the ball socket 2 is fixedly installed at the center of the upper surface of the ball socket base flange 1; the ball socket base flange 1 is fixedly connected to the ball socket 2 through bolts; the top of the ball socket 2 is provided with a spherical concave Groove; the rotating ball 3 extends into the spherical groove; the rotating ball 3 performs universal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com