Recovering device for plastic environment-friendly bag production

A technology for recycling devices and environmental protection bags, which is applied in the fields of recycling devices for production of plastic environmental protection bags and recycling devices for production. The effect of convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

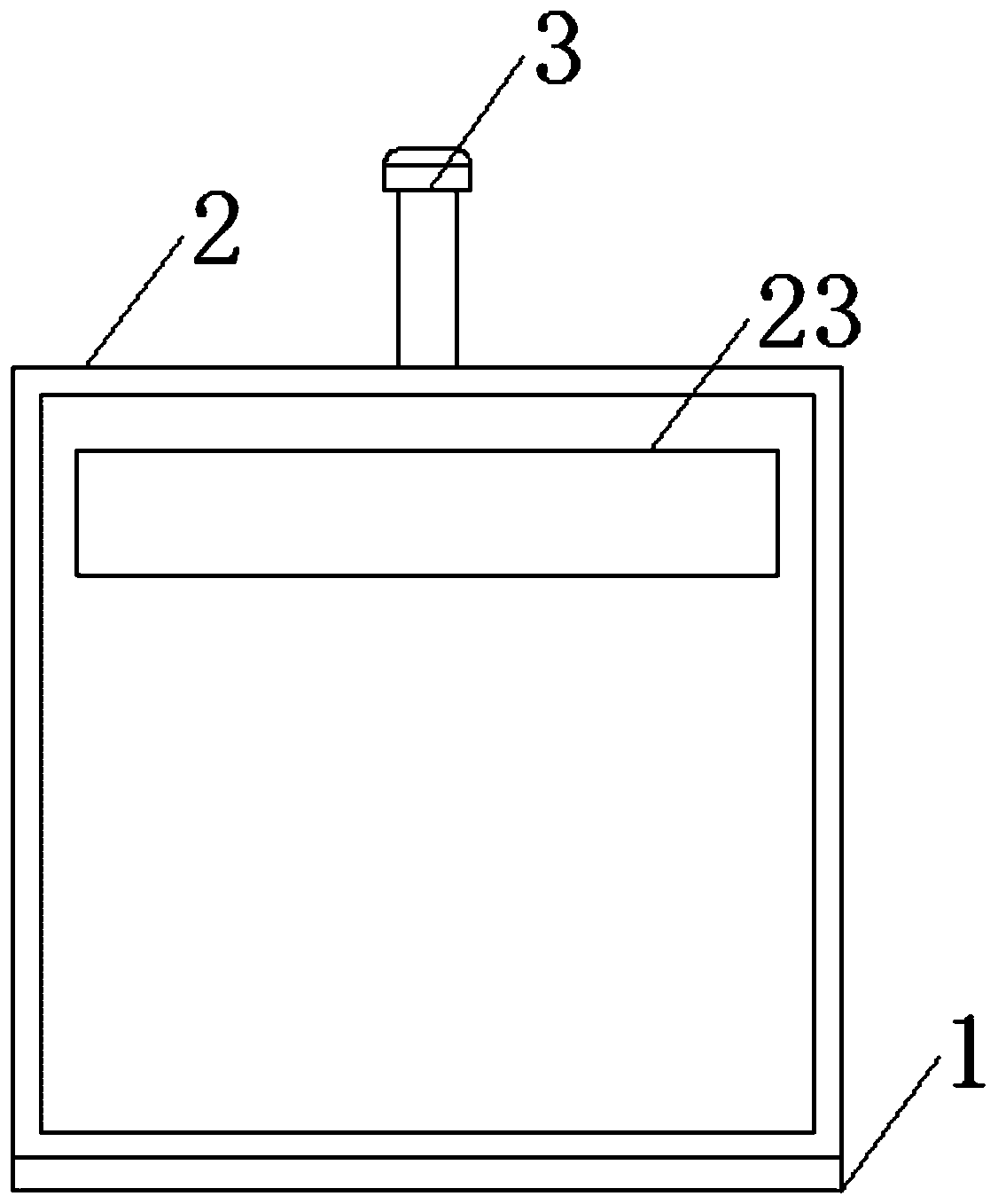

[0020] Such as Figure 1-4 As shown, a recovery device for the production of plastic environmental protection bags of the present invention comprises a base mechanism 1, an upper cover mechanism 2 and an extruding mechanism 3, the upper end of the base mechanism 1 is provided with an upper cover mechanism 2, and the upper cover mechanism 2 An extruding mechanism 3 is arranged above.

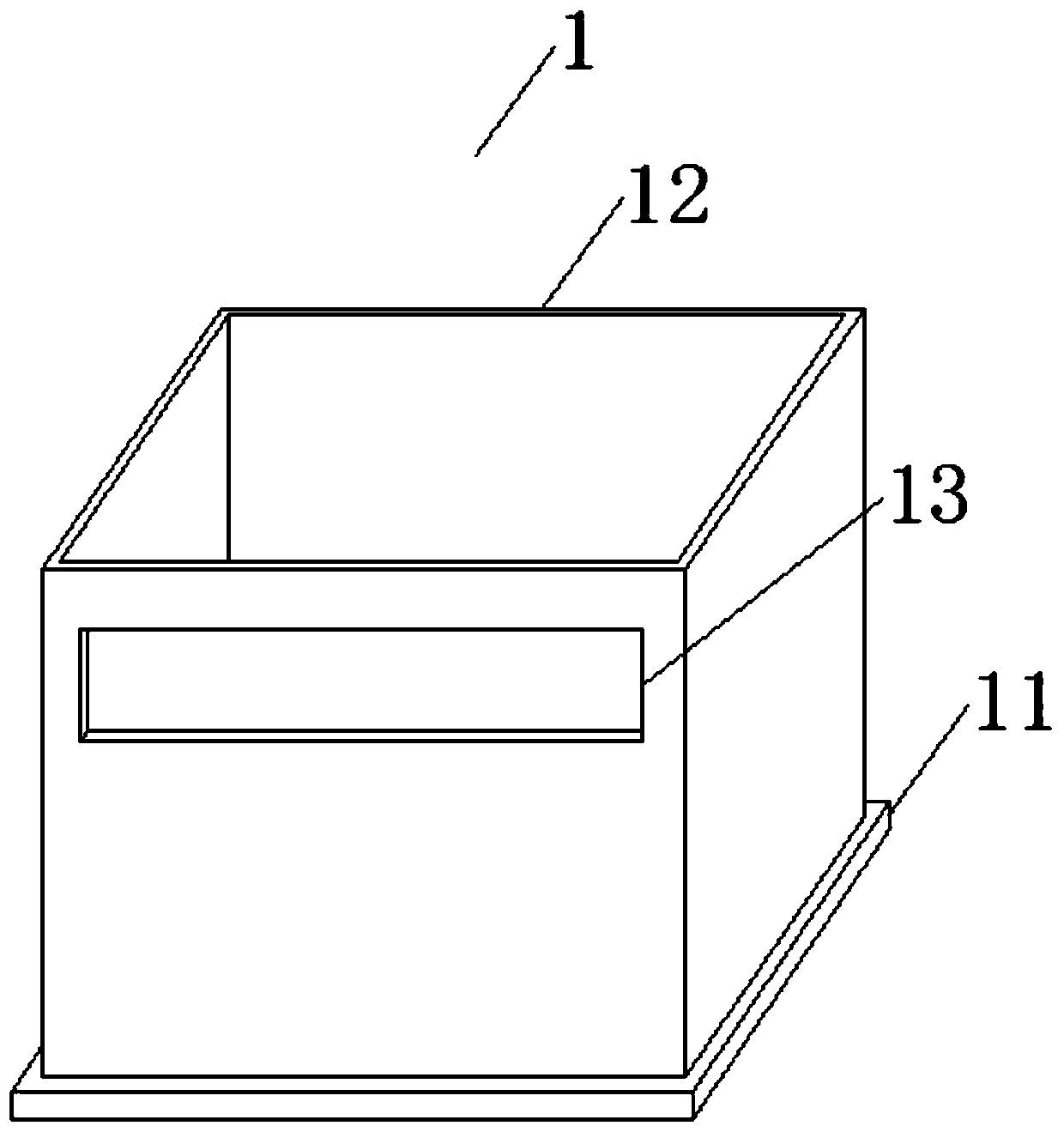

[0021] Wherein, the base mechanism 1 includes a base plate 11, the base plate 11 is arranged in a rectangular plate shape, an inner frame 12 is fixed vertically on the upper end surface of the base plate 11, and the outer wall of the inner frame 12 runs through a side close to the frame opening at the upper end. The inner cavity of the inner frame 12 is provided with an inner square hole 13 .

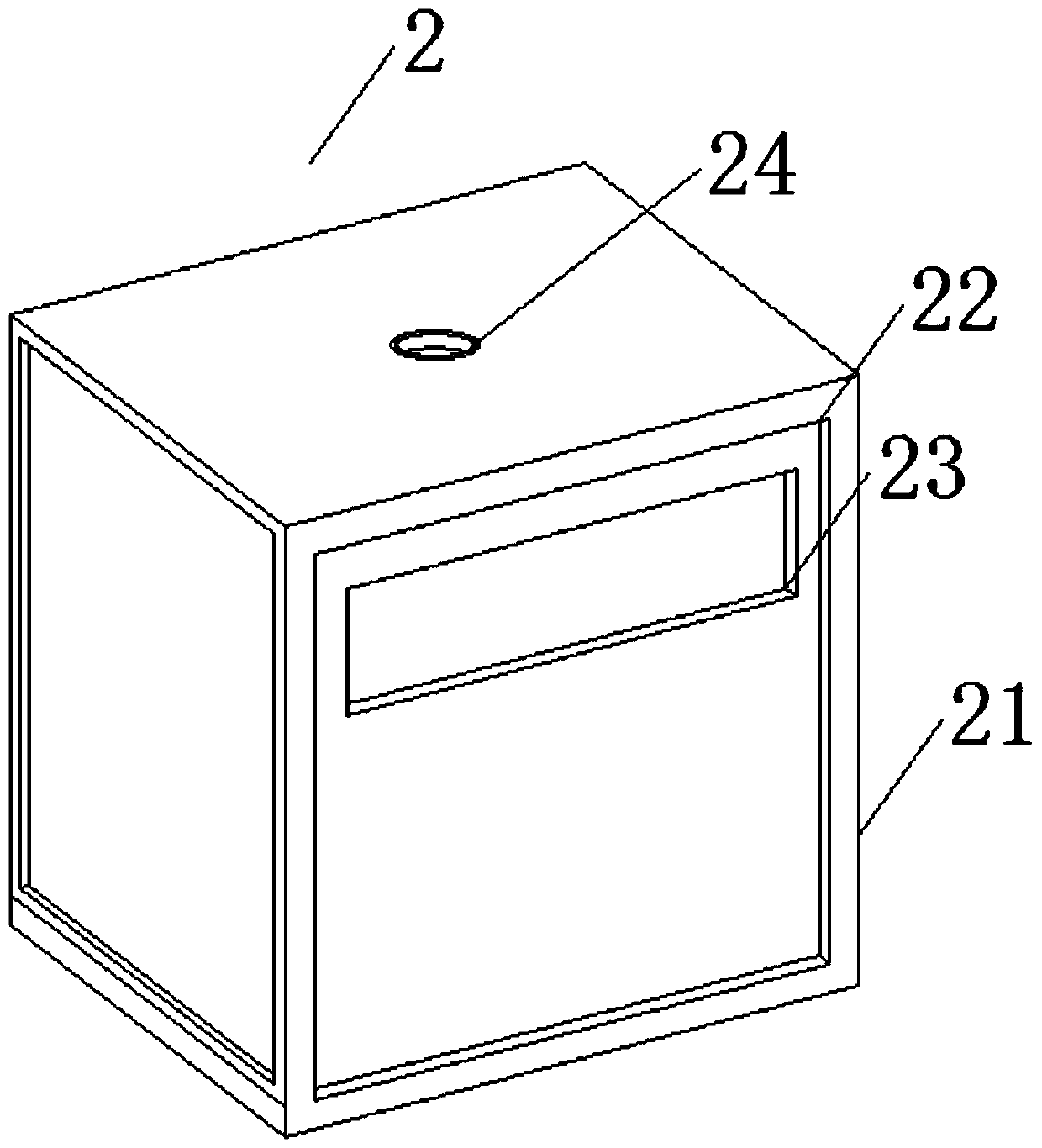

[0022] Wherein, the upper cover mechanism 2 includes a casing 21, the casing 21 is made of stainless steel, the four side walls of the casing 21 are provided with hollow grooves 22, and the four hollow gr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap