Safe elevator car

A technology for elevator cars and safety elevators, which is applied to elevators, lifts, transportation and packaging in buildings, and can solve the problems of reduced safety of elevator cars, easy reduction in the strength of heavy supports, and difficulties in the installation of heavy supports. Safety hazards are easy to find, assembly level requirements are low, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

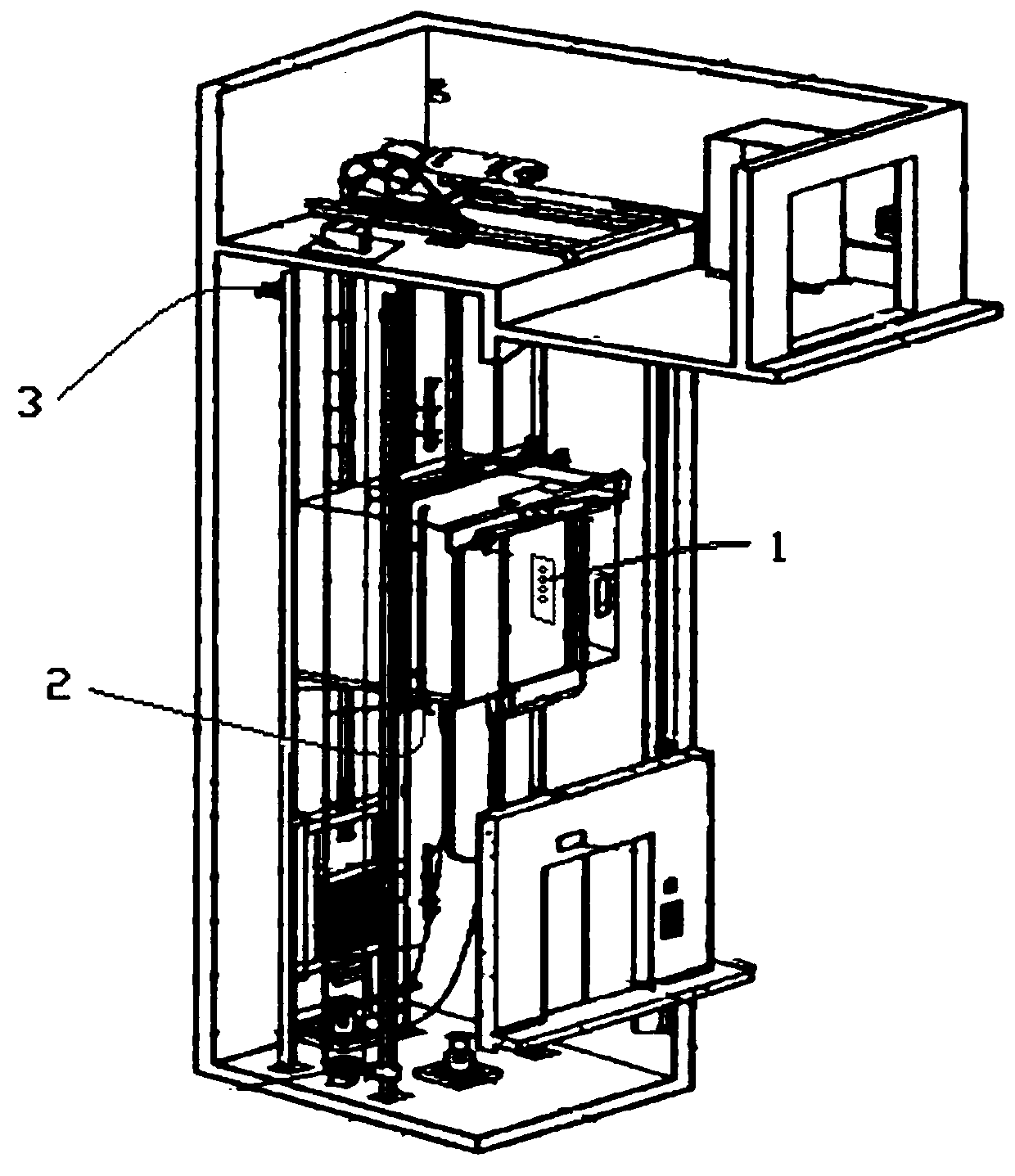

[0040] Example 1. A safety elevator car such as figure 1 As shown, the elevator car is provided with an elevator control cabinet 1, and the bottom of the elevator car is provided with an elevator lower beam 2, and the elevator car is connected with a counterweight mechanism; It is connected with the elevator car, the counterweight block is connected with the counterweight guide rail through the counterweight guide shoe, and the counterweight guide rail is fixed with the elevator shaft through the counterweight bracket 3.

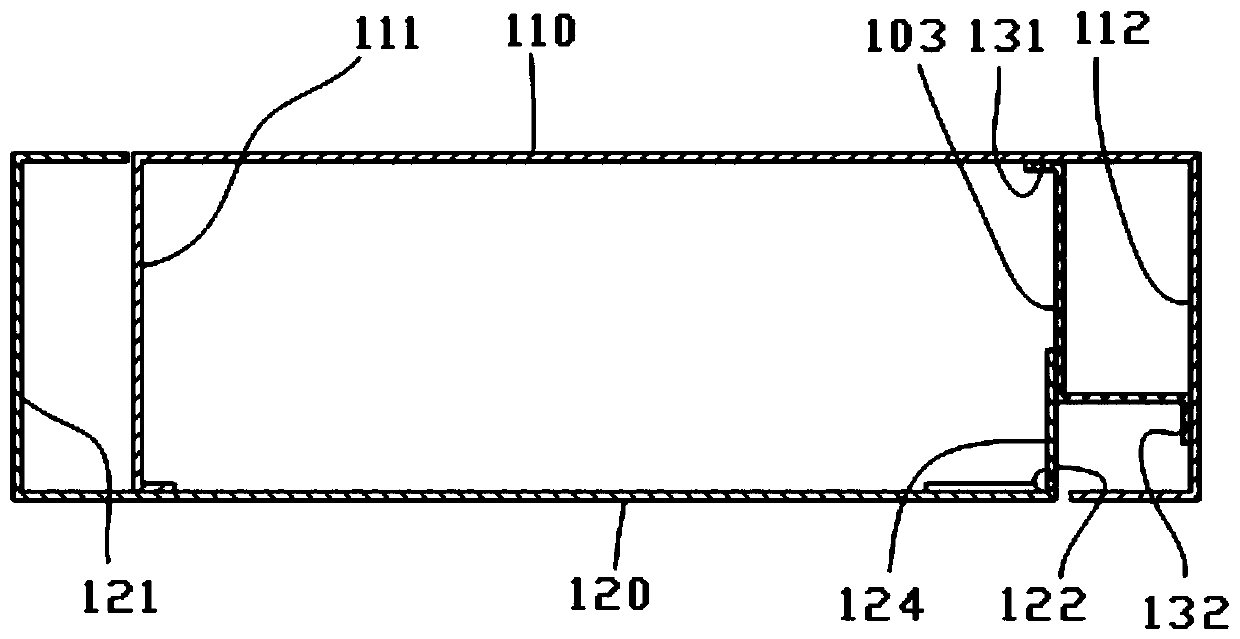

[0041] The elevator control cabinet 1 includes a bottom box and a cabinet door. The bottom box includes a bottom plate 110, one side of the bottom plate 110 is bent forward to form a first plate 111, and the other side of the bottom plate 110 is first forward and then inward. Bending to form a second plate 112; the cabinet door includes a panel 120 positioned at the front side of the bottom box, one side of the panel 120 is bent backward to form a third pla...

Embodiment 2

[0063] Example 2. The difference from Embodiment 1 is the structure of the lower beam 2 of the elevator. The lower beam 2 of the elevator in Embodiment 2 includes a bottom beam 21, a safety gear mounting plate 22 and two straight beam connecting plates 23 are provided at both ends of the bottom beam 21, and the bottom beam 21 is screwed to the safety gear mounting plate 22, Bottom beam 21 is screwed with straight beam connecting plate 23.

[0064] The bottom beam 21 includes two symmetrically distributed side beams 211. The side beams 211 are a U-shaped structure with an opening horizontally outward and are made of galvanized plate. The first installation hole 202, the two ends of side beam 211 are all provided with straight beam connecting plate 23, and described straight beam connecting plate 23 is the bent plate of L shape, material galvanized plate, and the end of side beam 211 is all provided with The first inserting plate 203 inserted into the straight beam connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com