Fracturing technology for improving effective support of shale fracturing complex fracture network

A complex fracture and fracturing technology, applied in the field of oil and gas stimulation and reconstruction, can solve the problem of not being able to play a good supporting role, and achieve the effects of strong migration capacity, reduced water consumption, and improved effective support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

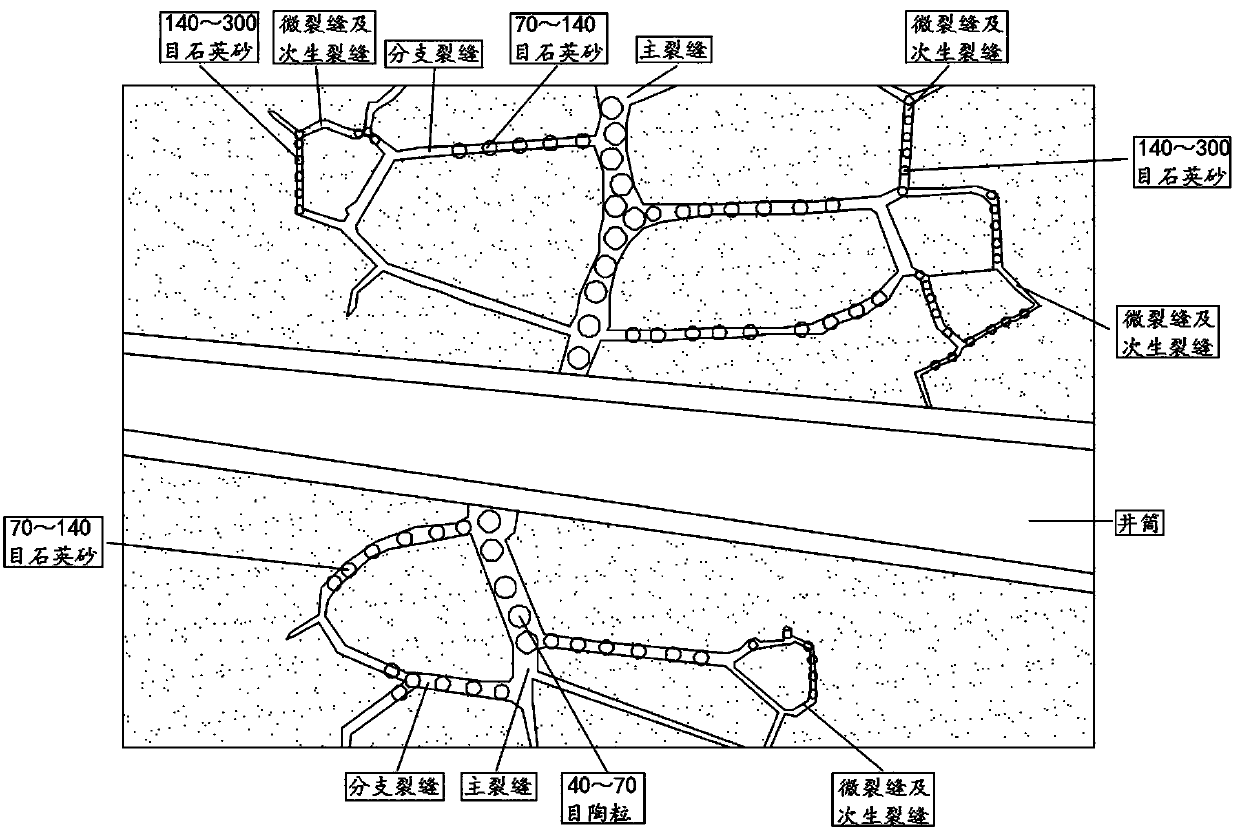

[0029] The invention discloses a fracturing process for improving the effective support of complex fracture networks in shale fracturing. According to the characteristics of different reservoirs, the process preferably adopts the sand-added fracturing process of pre-fluid + sand-carrying fluid + displacement fluid. The liquid volume of the section is preferably 1800m 3 , wherein, the volume percentage of the sand-carrying fluid is 88%, the volume percentage of the front fluid is 6%, and the volume percentage of the displacement fluid is 6%. The amount of sand added per meter of the horizontal section of the shale layer is 1.7 tons. It specifically includes the following steps:

[0030] (1) Cleaning the well: Use clean water or well flushing fluid to circulate and flush the well, and use the well drilling gauge to drill the well.

[0031] (2) Perforation: The perforating gun is transported into the well through the cable belt, and the perforation is carried out to create pore...

Embodiment 2

[0039] The invention discloses a fracturing process for improving the effective support of complex fracture networks in shale fracturing. According to the characteristics of different reservoirs, the process preferably adopts the sand-added fracturing process of pre-fluid + sand-carrying fluid + displacement fluid. The liquid volume of the section is preferably 1800m 3 , wherein, the volume percentage of the sand-carrying fluid is 92%, the volume percentage of the front fluid is 4%, and the volume percentage of the displacement fluid is 4%. The amount of sand added per meter of horizontal section length of the shale layer is 2.0 tons. It specifically includes the following steps:

[0040] (1) Cleaning the well: Use clean water or well flushing fluid to circulate and flush the well, and use the well drilling gauge to drill the well.

[0041] (2) Perforation: The perforating gun is transported into the well through the cable belt, and the perforation is carried out to create p...

Embodiment 3

[0049] The invention discloses a fracturing process for improving the effective support of complex fracture networks in shale fracturing. According to the characteristics of different reservoirs, the process preferably adopts the sand-added fracturing process of pre-fluid + sand-carrying fluid + displacement fluid. The liquid volume of the section is preferably 1800m 3 , wherein, the volume percentage of the sand-carrying fluid is 90%, the volume percentage of the front fluid is 5%, and the volume percentage of the displacement fluid is 5%. The amount of sand added per meter of horizontal section length of the shale layer is 1.85 tons. It specifically includes the following steps:

[0050] (1) Cleaning the well: Use clean water or well flushing fluid to circulate and flush the well, and use the well drilling gauge to drill the well.

[0051] (2) Perforation: The perforating gun is transported into the well through the cable belt, and the perforation is carried out to create ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com