New energy automobile battery pack support

A technology for new energy vehicles and battery packs, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of lack of support for the protruding part of the battery pack, lack of cavity support, and discontinuous rigidity, etc., to improve continuity, Reduce structure noise and enhance the effect of natural modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

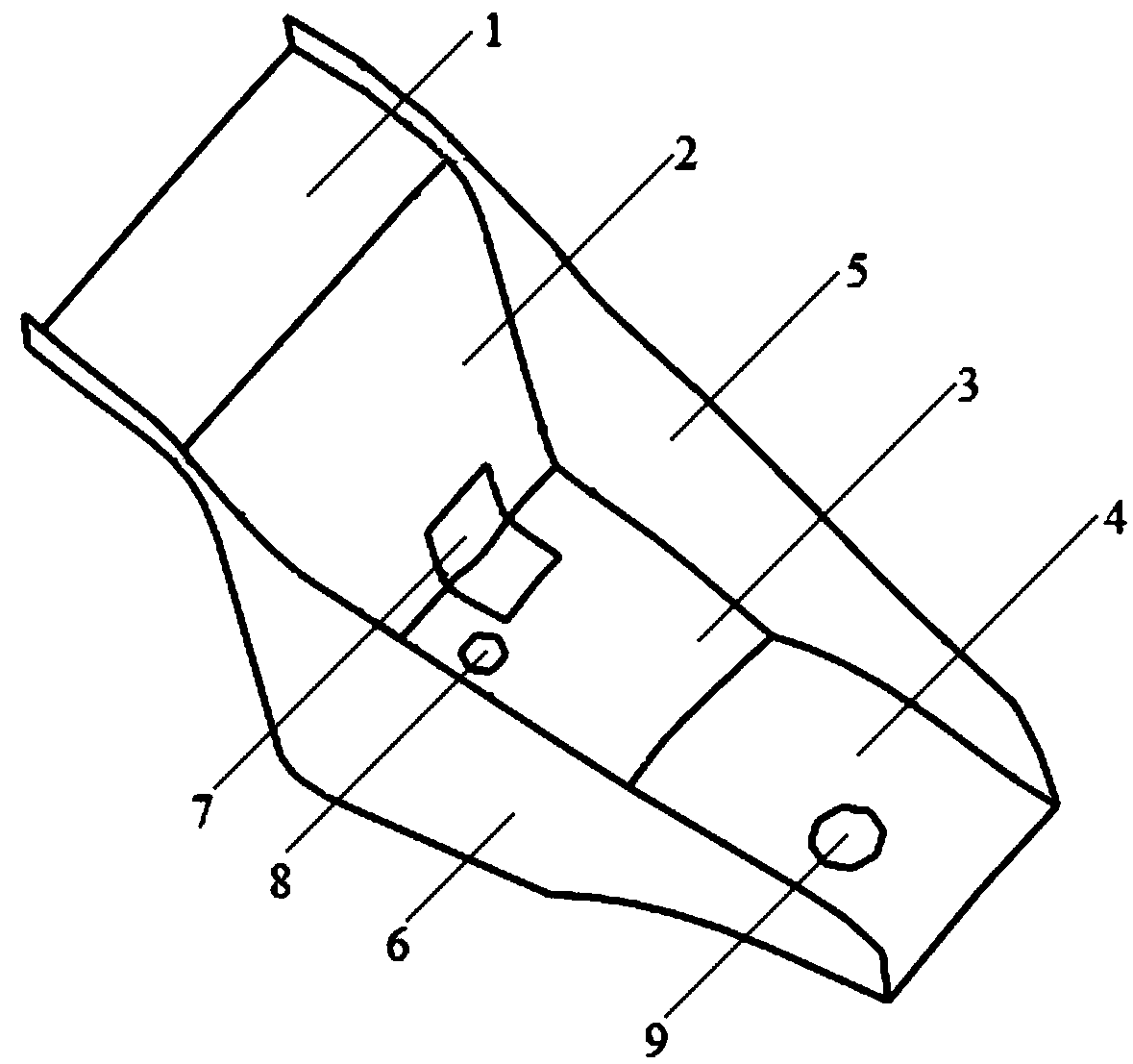

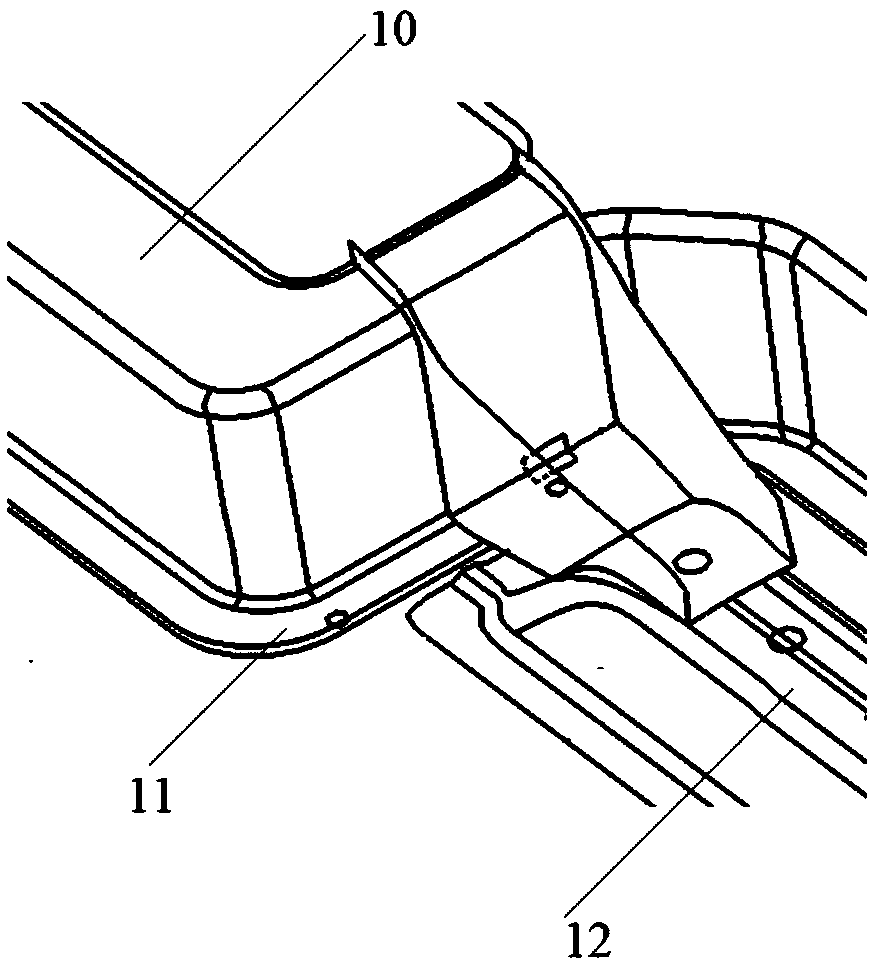

[0020] A schematic structural diagram of a battery pack bracket for a new energy vehicle according to an embodiment of the present invention is as follows figure 1 , 2 As shown, the bracket is installed between one side of the protruding part 10 of the battery pack and the floor beam 12, and the bracket is in the shape of a dustpan as a whole, including a first horizontal plane 1, a vertical plane 2, a second horizontal plane 3, and an inclined plane 4 and the first side 5 and the second side 6 which are symmetrical to the centerline of the bracket and are perpendicular to and adjacent to the first horizontal plane 1 , the vertical plane 2 , the second horizontal plane 3 and the inclined plane 4 . The first horizontal plane 1 fits and fixes with the upper surface of the protruding portion 10 of the battery pack; the vertical plane 2 fits and fixes together w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com