Pipeline filtering device with self-cleaning function

A filter device and self-cleaning technology, which is applied in the direction of filter separation, separation methods, chemical instruments and methods, etc., can solve the problems of manual disassembly, inconvenient cleaning, trouble, etc., and achieve the effect of improving service life and environment, and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

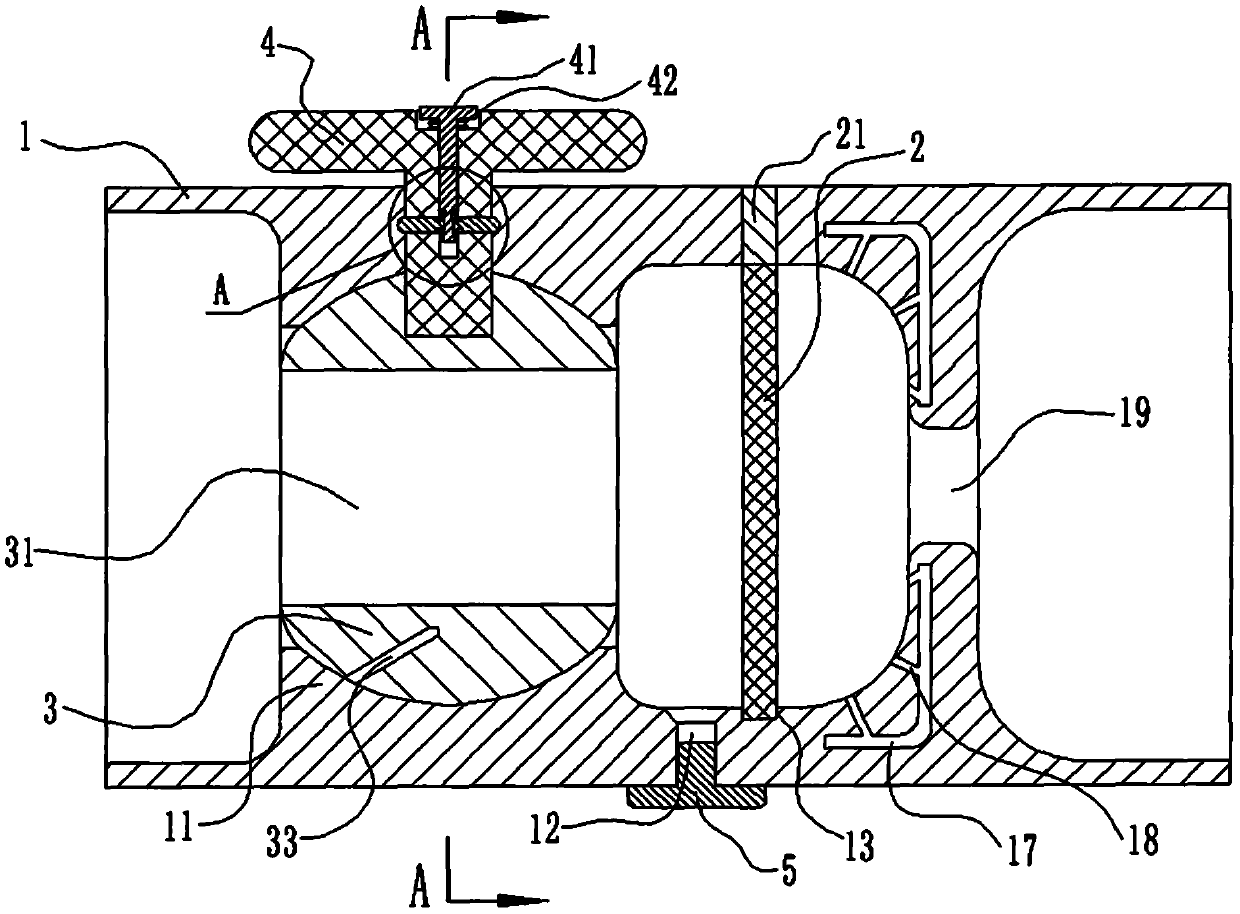

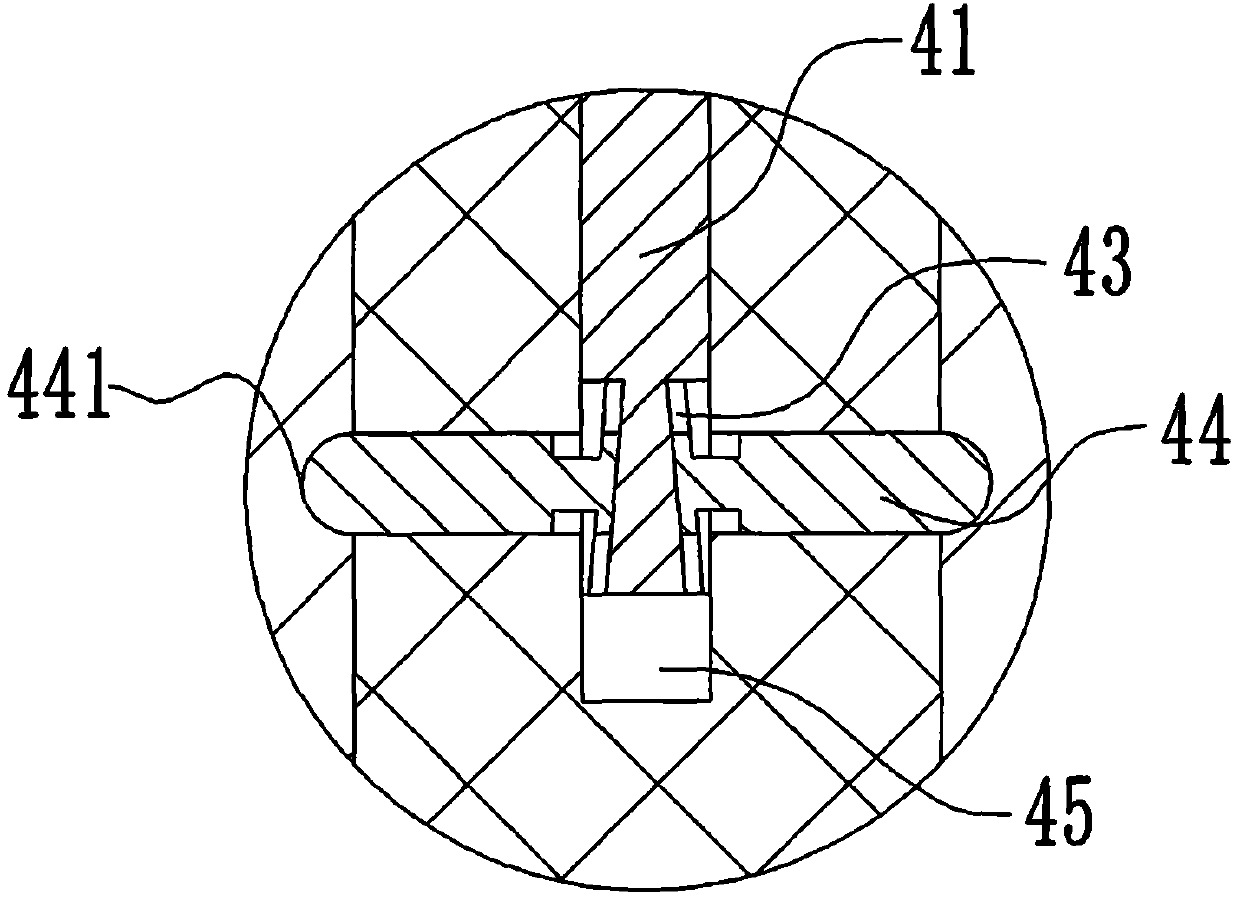

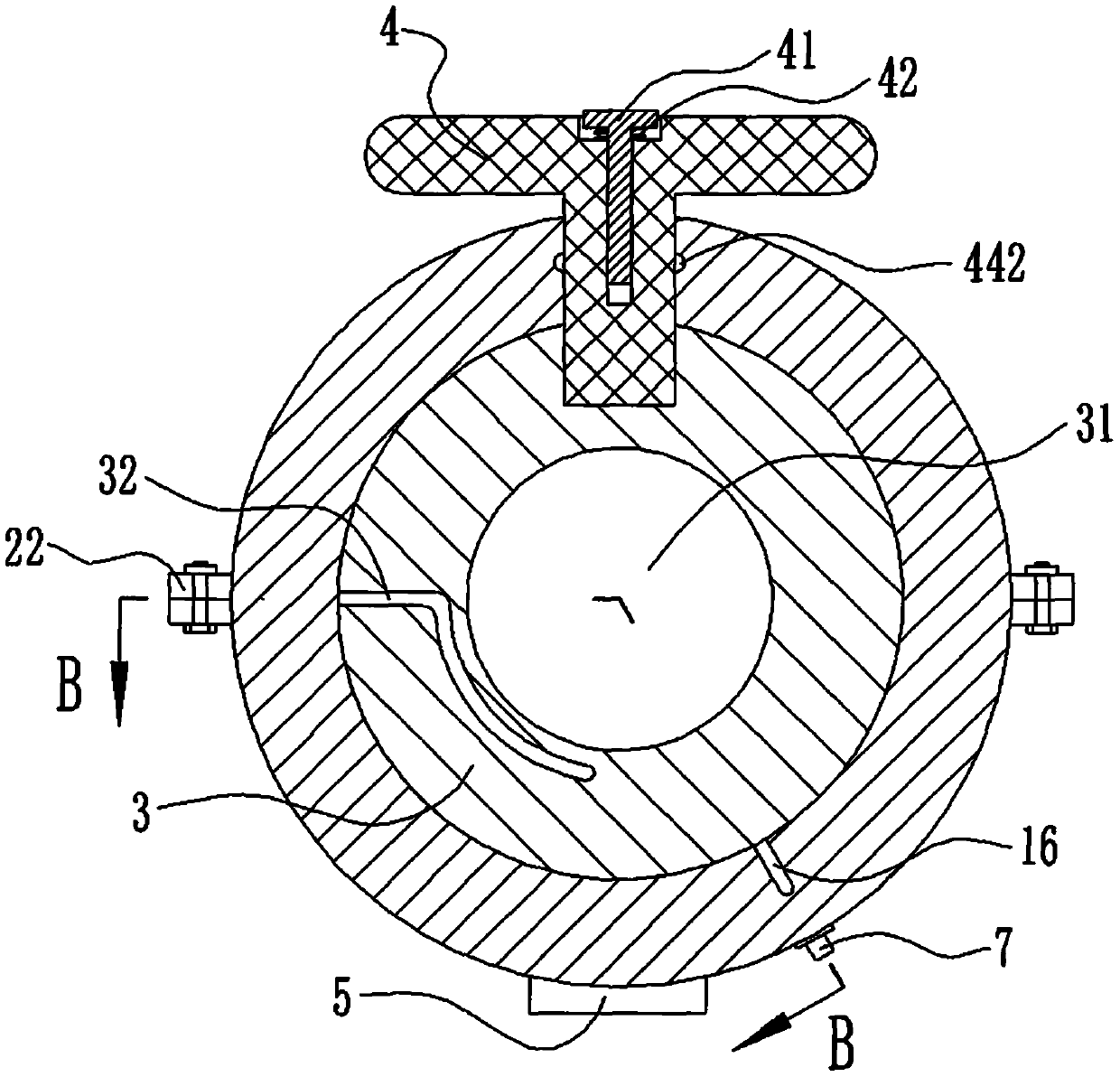

[0033] like Figure 1-6 As shown, a pipeline filter device with self-cleaning function includes an outer wall 1 and a filter screen 2. The outer wall 1 is in the shape of a circular tube, and the two ends can be connected to structures such as pipes and faucets. The two ends of the outer wall 1 can also have other shapes. The net 2 is arranged on the middle front end inside the outer wall 1, and the left side of the filter screen 2 is provided with an annular concave platform 11 formed on the outer wall 1, and a water outlet 19 is provided on the right side, and the annular concave platform 11 is rotatably provided with The ball valve 3 is provided with a valve hole 31 at the center of the ball valve 3 for through-flow, and a ball valve hand wheel 4 is fixedly connected above the ball valve 3 .

[0034] In order to further improve the performance of the present invention, a recoil inlet pipe 32 is provided on the ball valve 3 and perpendicular to the axis of the valve hole 31,...

Embodiment 2

[0045] Compared with Embodiment 1, this embodiment is characterized in that a boss 61 is provided outside the sewage outlet 12, and a cap 6 is provided outside the boss 61, and the cap 6 is connected to the boss 61 through threads.

[0046] The use process and working principle:

[0047] First, connect corresponding structures on the outer walls 1 at both ends of the present invention, such as water pipes, faucets and other structures.

[0048] During normal use, firstly plug the sewage outlet 12 with the piston 5 or the cap 6, then install the filter, and then press the reset shaft 41 to rotate the hand wheel 4 of the ball valve. After a certain angle of rotation, it can be released and reset Press the shaft 41 to continue to rotate the ball valve handwheel 4. When the rotation does not stop, the staple 44 has been inserted into the valve opening groove 441 under the action of the first return spring 42. At this time, the ball valve 3 is in the open state, that is, the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com