Seat belt retractor

A technology of seat belt retractor and seat belt, which is applied in the directions of seat belts, belt tensioners, belt fixing devices in the vehicle, etc., can solve the problems of installation on vehicle seats and increased structural space requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

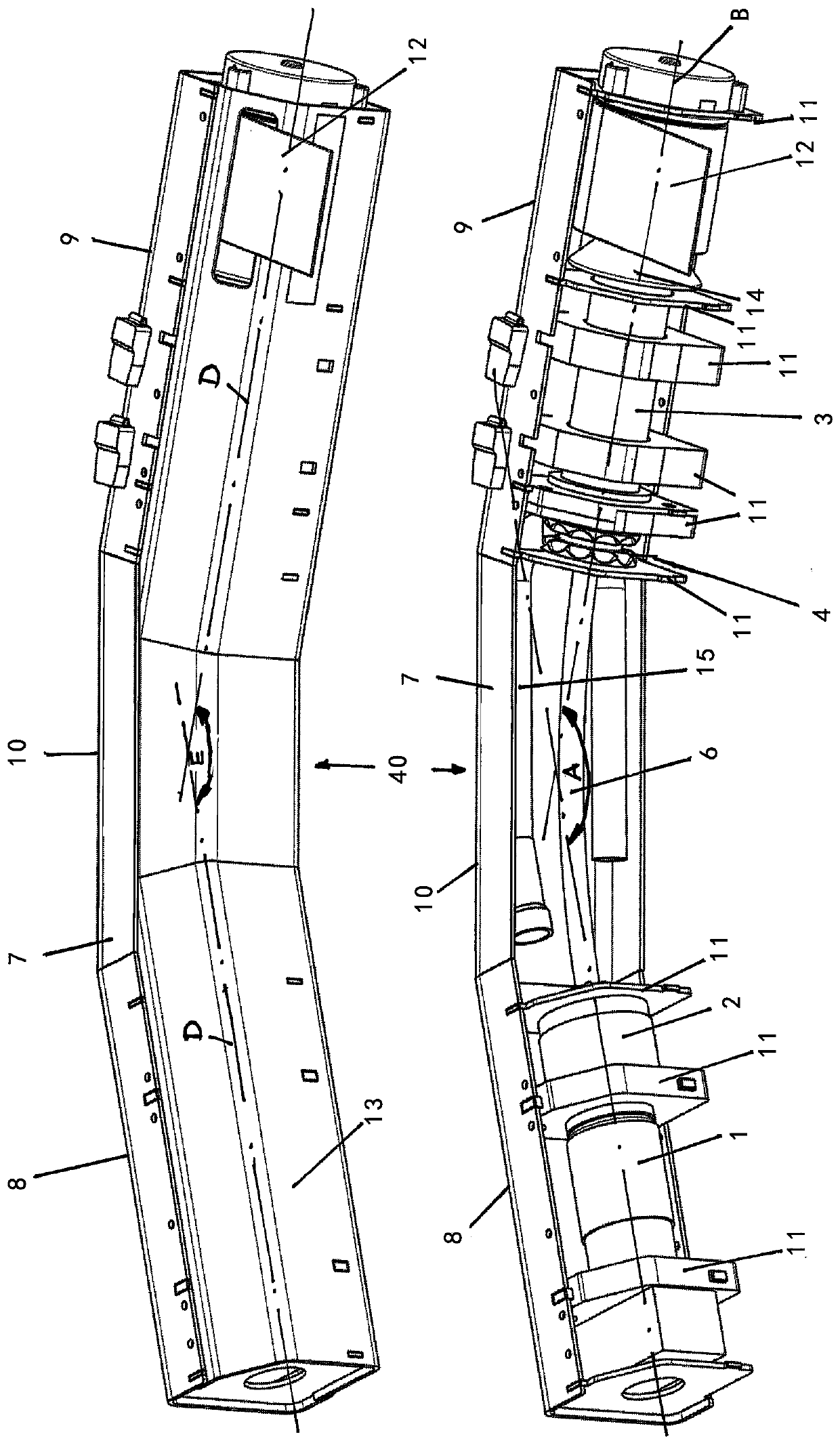

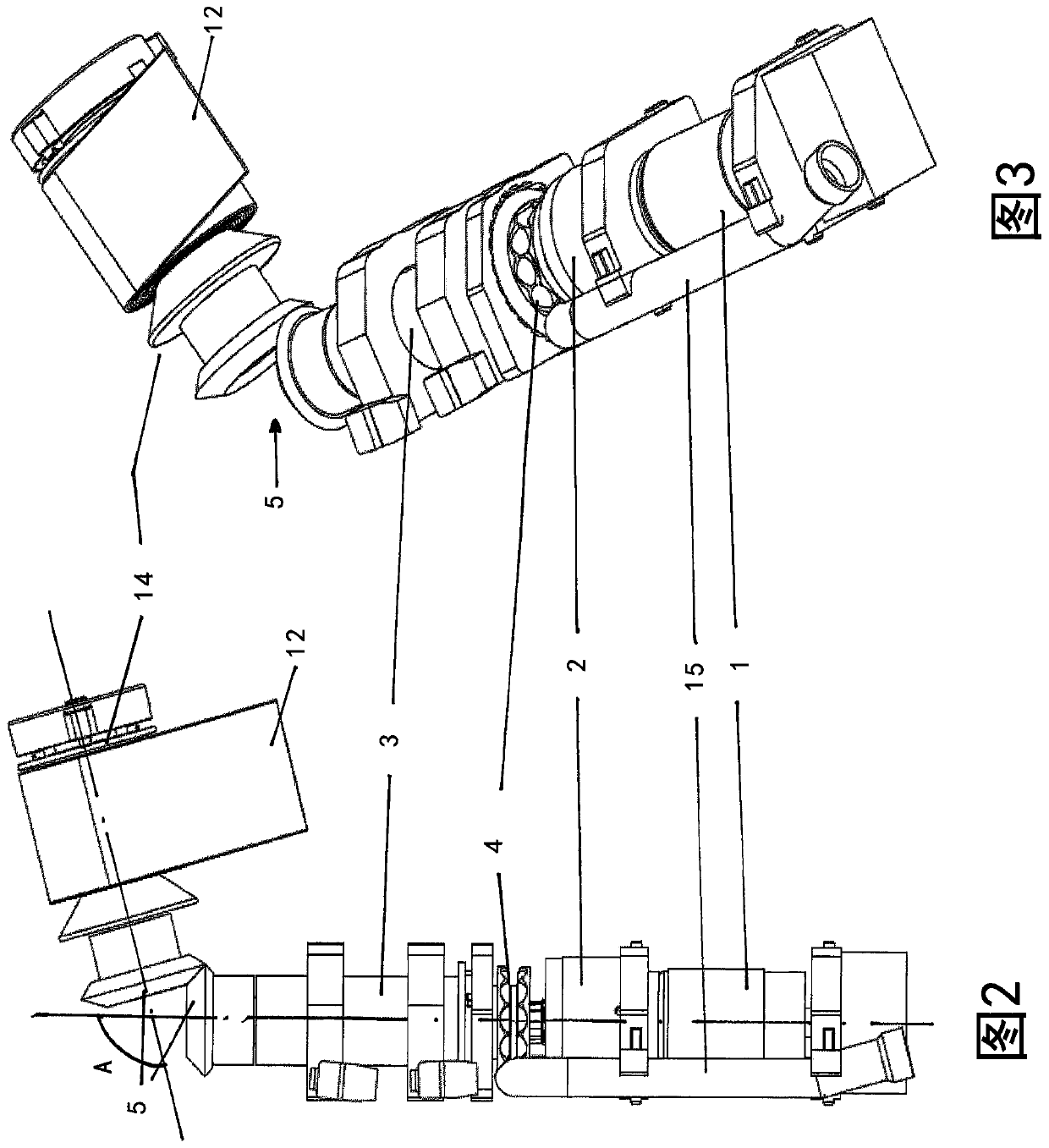

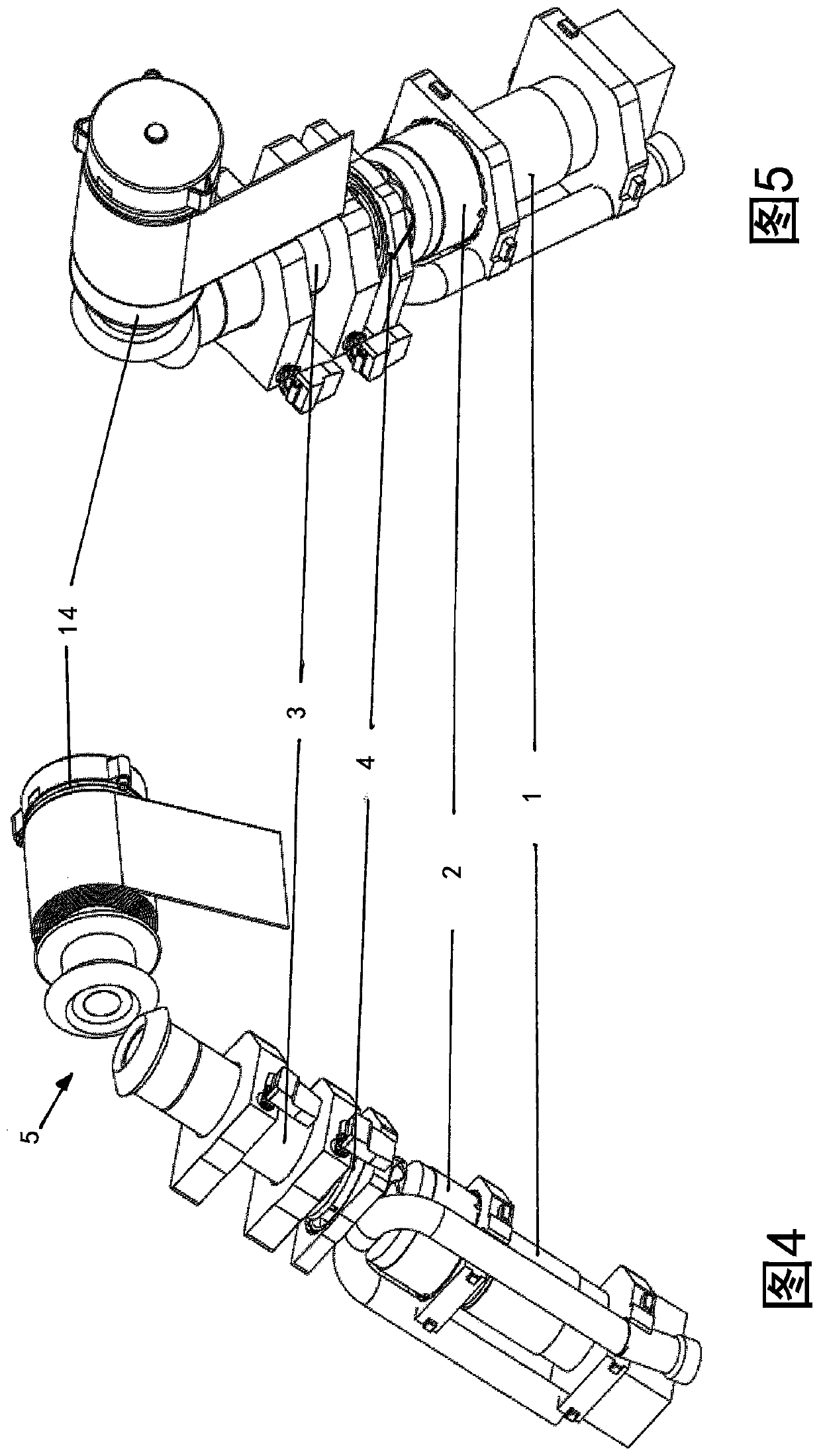

[0028] exist figure 1 with Image 6 In the figure, a seat belt retractor 40 according to a preferred embodiment of the invention can be seen, which has a seat belt 12 which can be wound on a seat belt reel 14 . The belt retractor 40 has a housing 7 comprising two spaced apart housing parts 8 and 9 and a housing intermediate part 10 arranged between the housing parts 8 and 9, for better identifiability, already in Image 6The housing intermediate piece 10 is omitted in the illustration. The housing parts 8 and 9 and the housing intermediate part 10 are configured as an elongated U-shaped profile and are arranged such that the two spaced apart housing parts 8 and 9 surround each other by less than 180° with their longitudinal axes D. degrees but greater than 90 degrees and are connected to each other through the housing intermediate piece 10 . The open sides of the housing parts 8 and 9 and of the housing middle part 10 are each covered by a cover part 13 to form a closed pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com