Lubricating oil amount adjustment mechanism, compressor, refrigerator

A technology for adjusting structure and oil volume, applied in the field of compressor manufacturing, can solve the problems of excessive lubricating oil, affecting the performance of the system heat transfer efficiency, compressor performance, and high system oil discharge rate, so as to prevent the exhaust with large oil volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

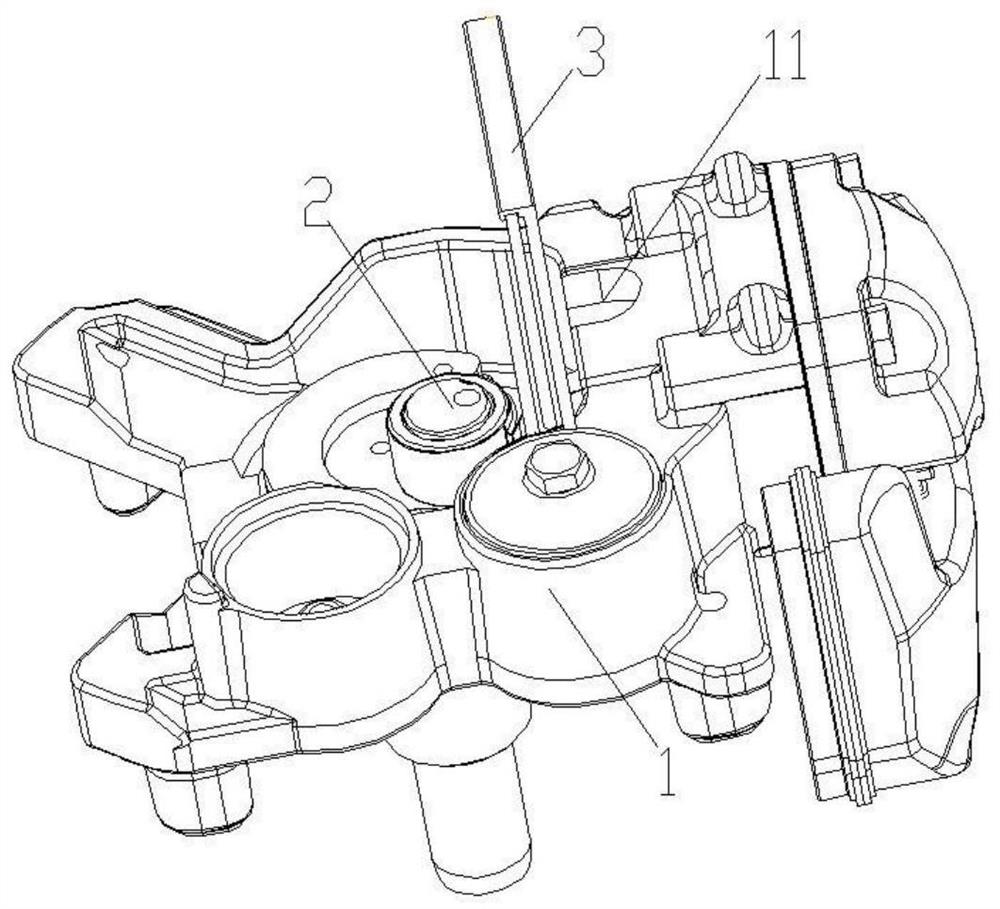

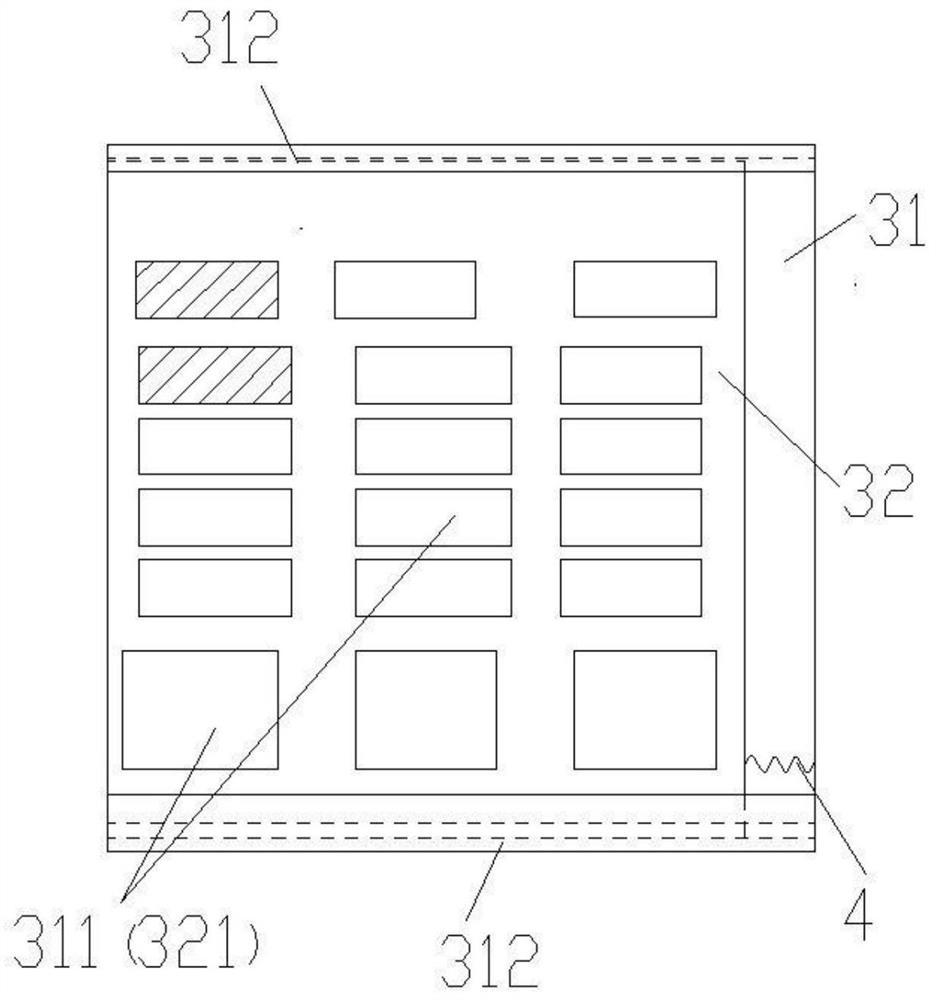

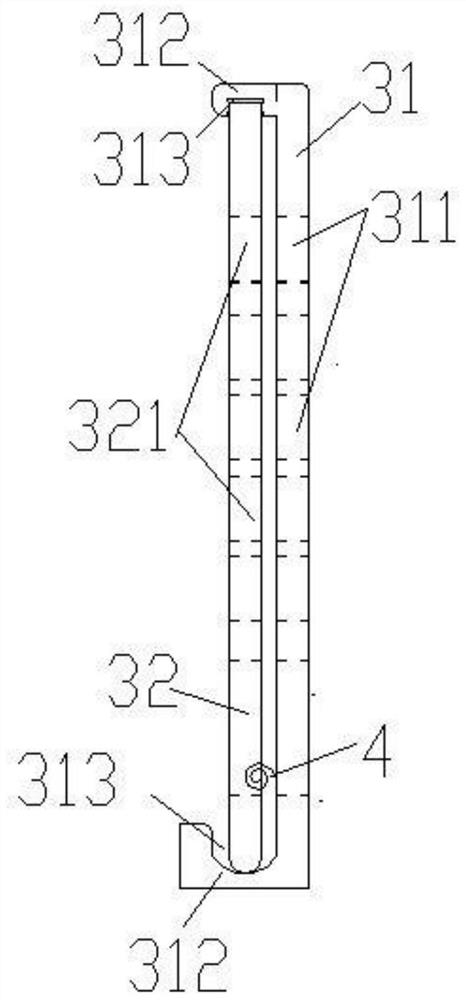

[0021] see in conjunction Figure 1 to Figure 4 As shown, according to an embodiment of the present invention, a lubricating oil amount adjustment structure is provided, including a cylinder block 1 and a crankshaft 2, the cylinder block 1 has a cylinder portion, the crankshaft 2 is rotatably connected to the cylinder block 1, and the A groove 11 is configured on the cylinder part. It can be understood that the groove 11 runs through the inside and outside of the cylinder part. The purpose of the groove 11 is to facilitate the assembly of the connecting rod in the compressor. The U-shaped groove can also be grooves of other shapes, and the present invention is not particularly limited. An oil volume adjustment assembly 3 is also provided between the groove 11 and the crankshaft 2, and the oil volume adjustment assembly 3 The amount of lubricating oil thrown into the groove 11 by the lubricating oil thrown off by the crankshaft 2 can be adjusted. In this technical solution, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com