Reverse E-type tailoring method for female jeans

A technology for jeans and trousers, which is applied in the field of jeans cutting, can solve problems such as the inconsistency of the size of the crotch and the hips, and achieve the effects of size coordination, high matching degree and simple calculation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

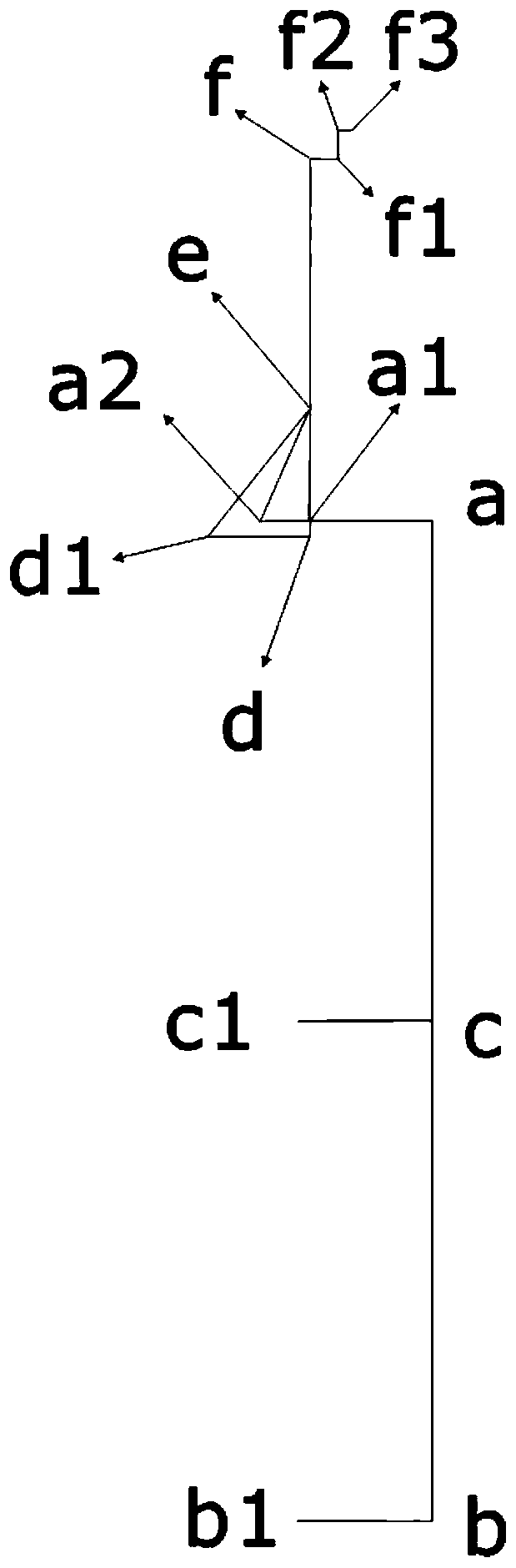

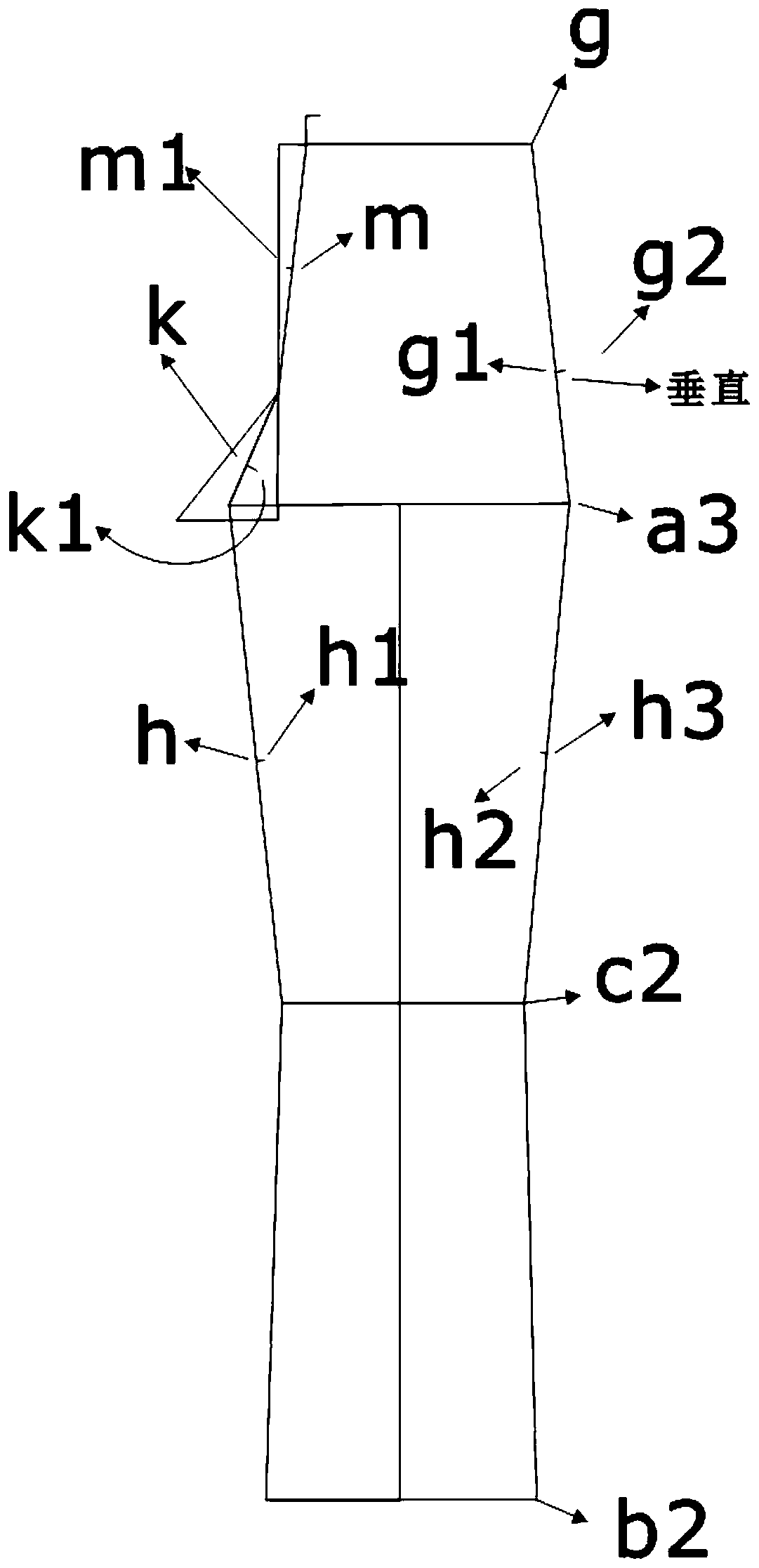

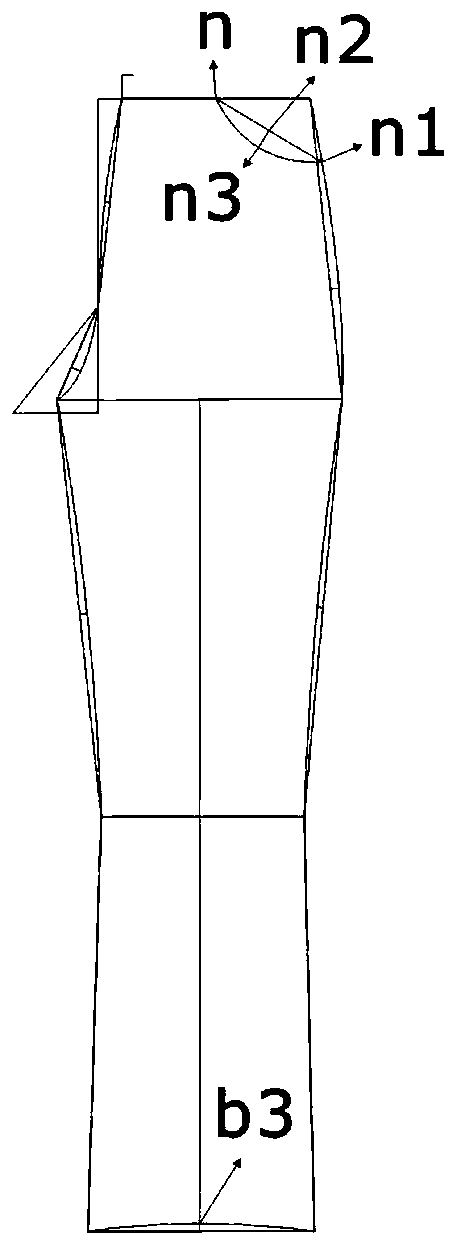

[0042] A kind of anti-E type cutting method of women's jeans, such as figure 1 As shown, it is the reverse E type plate-making drawing of the present invention, number / type is 160 / 70A, waist circumference=70cm, hip circumference=90cm are example, and this method comprises:

[0043] (1) Draw anti-E structure

[0044] Draw horizontal crotch midpoint a and trouser opening midpoint b, take ab as anti-E formula axis length, the length=0.482*number of line segment ab=0.482*160cm=77.12cm, make midpoint knee point c of ab, respectively from a, Points c and b are used as the vertical line segment of ab to the front crotch point a1, the left point of the knee c1 and the left point of the trousers b1, aa1 is the length of the upper side of the reverse E type, cc1 is the length of the middle side of the reverse E type, and bb1 is the bottom side of the reverse E type Long, the length of line segment aa1=the length of line segment cc1=0.103*hip circumference=0.103*90cm=9.27cm, the length ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com