Position control method and control device, roller washing machine and storage medium

A technology of a drum washing machine and a control method, which is applied to the control device of the washing machine, the washing device, the textile and the papermaking, etc., can solve the problems of wear and tear of clothes, too rough washing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

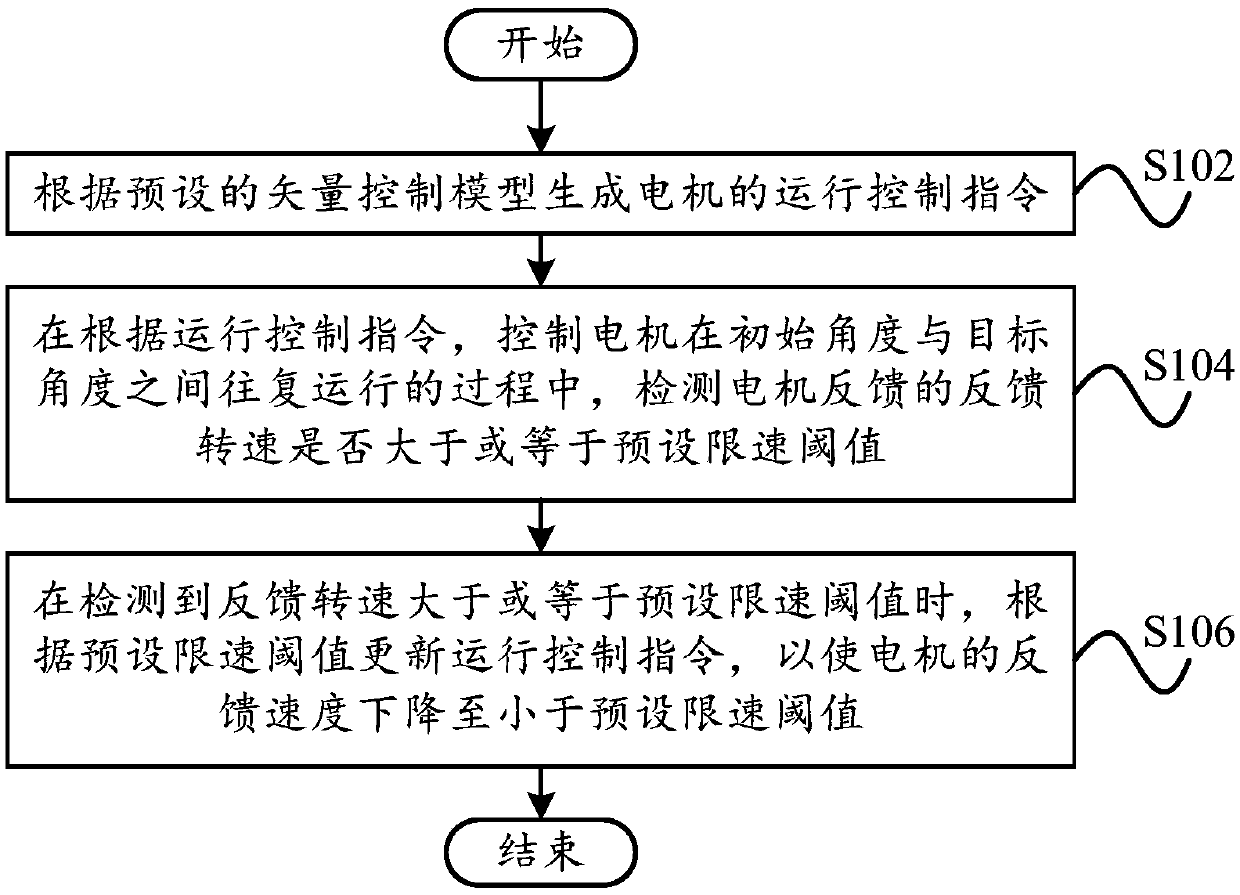

[0077] Such as figure 1 As shown, the position control method of a drum washing machine according to an embodiment of the present invention is applicable to a drum washing machine, and the method includes: step 102, generating an operation control command of the motor according to a preset vector control model; Run the control command to control the motor during the reciprocating operation between the initial angle and the target angle, and detect whether the feedback speed of the motor feedback is greater than the preset speed limit threshold; step 106, when it is detected that the feedback speed is greater than the preset speed limit threshold, The running control instruction is updated according to the preset speed limit threshold, so that the feedback speed of the motor decreases to be less than or equal to the preset speed limit threshold.

[0078] In this embodiment, the operation control of the motor is carried out through the preset vector control model, which is diffe...

Embodiment 2

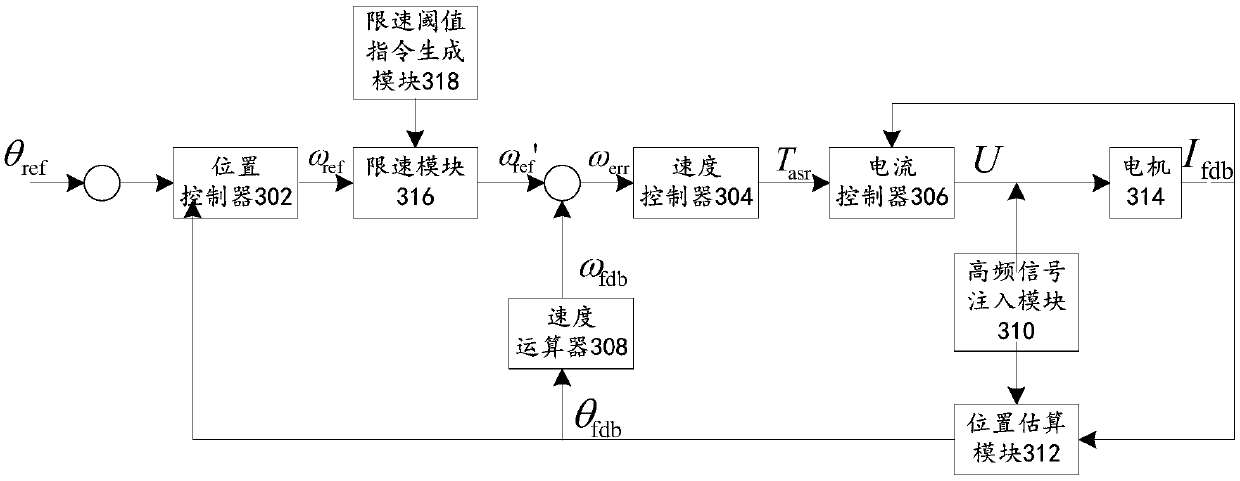

[0104] Such as image 3 As shown, when it is detected that the feedback speed is greater than the preset speed limit threshold, the operation control instruction is updated according to the preset speed limit threshold, so that the feedback speed of the motor drops to less than or equal to the preset speed limit threshold, specifically including:

[0105] The main control module of the drum washing machine is used to send the drum position control command θ ref , which is the target angle.

[0106] The position controller 302 is used to receive the master control position instruction θ ref and with the motor position θ fdb Generate speed control command ω ref ;

[0107] Speed calculator 308, used to obtain the feedback speed ω fdb , that is, the above ω c ;

[0108] A speed limit threshold command generating module 318, configured to generate a preset speed limit threshold ω ref ';

[0109] The speed limit module 316 is configured to limit the speed control command ...

Embodiment 3

[0127] Such as Figure 4 As shown, when the feedback speed is detected to be less than the preset speed limit threshold, the operation control command generated according to the target angle is used to control the motor operation without the intervention of the speed limit module. The vector control model specifically includes:

[0128] The main control module of the drum washing machine is used to send the drum position control command θ ref ;

[0129] The position controller 402 is used to receive the master position instruction θ ref , and with the motor position θ fdb Generate speed control command ω ref ;

[0130] Speed calculator 408, used to obtain the feedback speed ω fdb , that is, the above ω c ;

[0131] The speed controller 404 is used to control the instruction ω through the speed ref and feedback speed ω fdb Generate torque control command T asr ;

[0132] The current controller 406 is used to control the instruction T through the torque asr with fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com