Slide holding device of rotary compressor and control method thereof

A rotary compressor and retaining device technology, which is applied to rotary piston machines, rotary piston pumps, rotary piston/swing piston pump components, etc., and can solve problems such as damage to sliding vanes, unstable vibration of sliding vanes, etc. , to prolong the service life, prevent damage to the slide, and prevent the sound of the slide from beating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

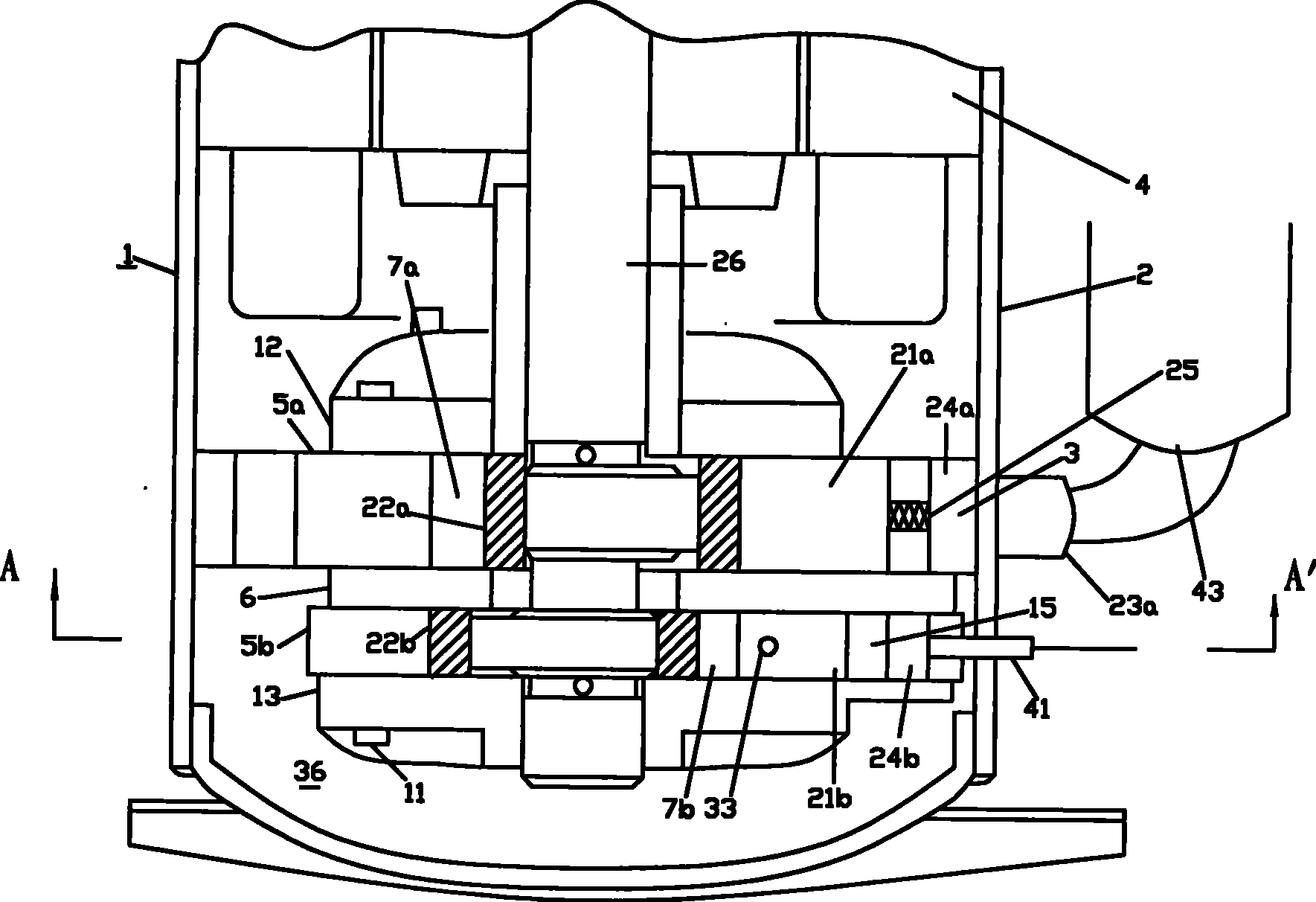

[0028] See figure 1 , Is the internal structure of the rotary compressor 1 of the present invention. The internal pressure of the sealed housing 2 is on the high-pressure side, a compression assembly 3 is provided at the lower part, and a motor 4 is provided at the upper part, and their outer diameters are fixed to the inner diameter of the housing 2. The compression assembly 3 has two cylinders, a first cylinder 5a and a second cylinder 5b. The two cylinders are separated by a central partition 6 to form a first cylinder cavity 7a and a second cylinder 7b, respectively. Wherein, the displacement of the second cylinder 5b is smaller than the displacement of the first cylinder 5a, and the method to realize this design is to change the height dimension of any cylinder.

[0029] On the upper surface of the first cylinder 5a and the lower surface of the second cylinder 5b, the main bearing 12 and the auxiliary bearing 13 are installed with screws 11 respectively. In the sealed first ...

no. 2 example

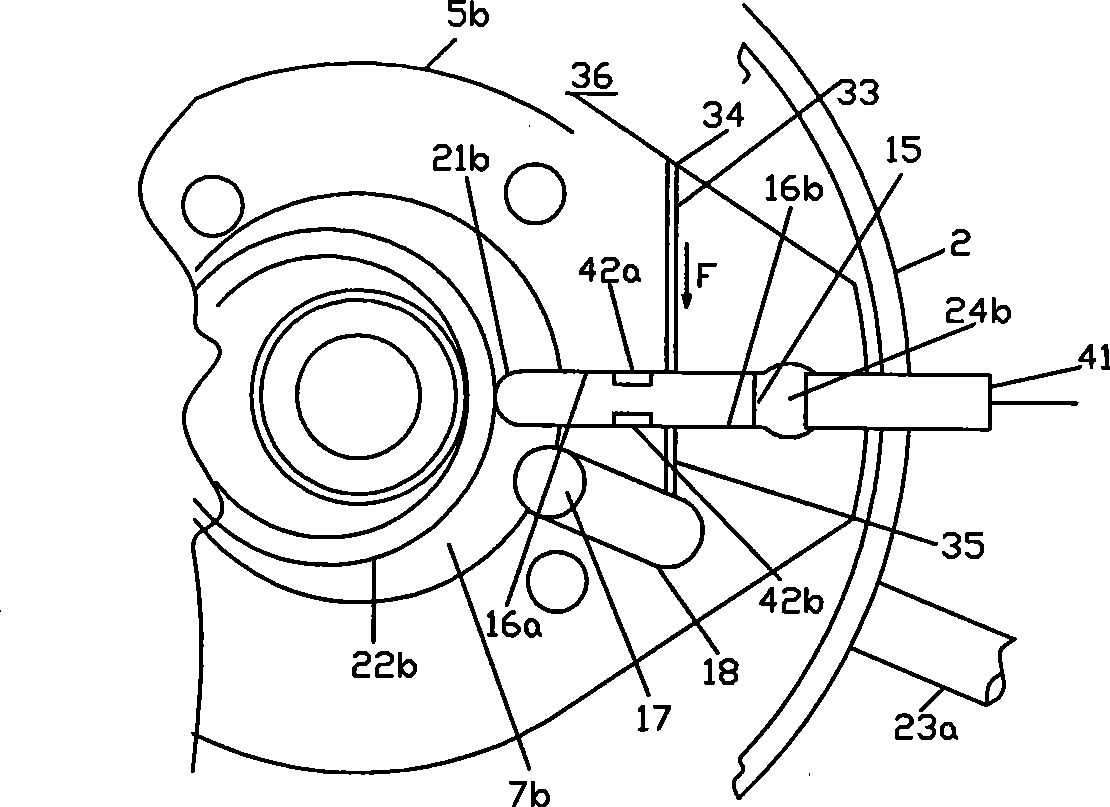

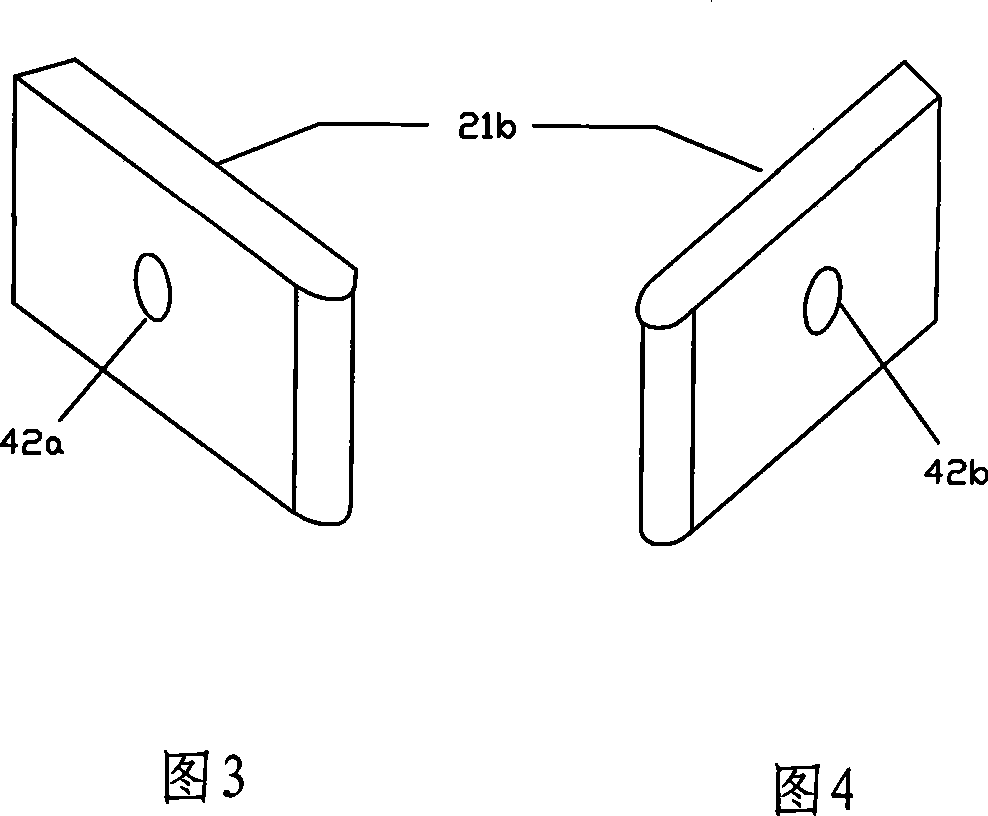

[0052] See Figure 7 In this embodiment, the design solution of the low pressure hole 35 used in the first embodiment is omitted. When the second sliding vane cavity 24b is switched to the low pressure side and the compression is stopped, in the two gaps between the second sliding vane 21b and the sliding vane groove 15, the gap between the sliding vane groove H surface 16a is affirmed by the function of the first recess 42a On the high-pressure side, the gap between the sliding vane groove L surface 16b is partially low-pressure even if there is no low-pressure hole 35, so a force F is generated. Therefore, some design schemes of rotary compressors can adopt the second embodiment.

no. 3 example

[0054] See Figure 8 with Picture 9 In this embodiment, the second recess 42b is designed to replace the low pressure hole 35 described in the first embodiment. On the side surface of the second sliding piece 21b, a bypass groove 37 opening in the second sliding piece cavity 24b communicates with the second recess 42b.

[0055] When the second sliding vane chamber 24b is switched to the high pressure side and the second cylinder chamber 7b continues to compress, the bypass groove 37 and the second recess 42b are both on the high pressure side. Because the high-pressure hole 34 and the first recess 42a are also on the high-pressure side, the force F on the side of the sliding blade is almost zero.

[0056] When the second vane cavity 24b is switched to the low pressure side, the bypass groove 37 and the second recessed portion 42b are both on the low pressure side, so the force F almost equal to that of the first embodiment is generated. Therefore, the second sliding piece 21b is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com