Flaring-shaped spray header and washing machine

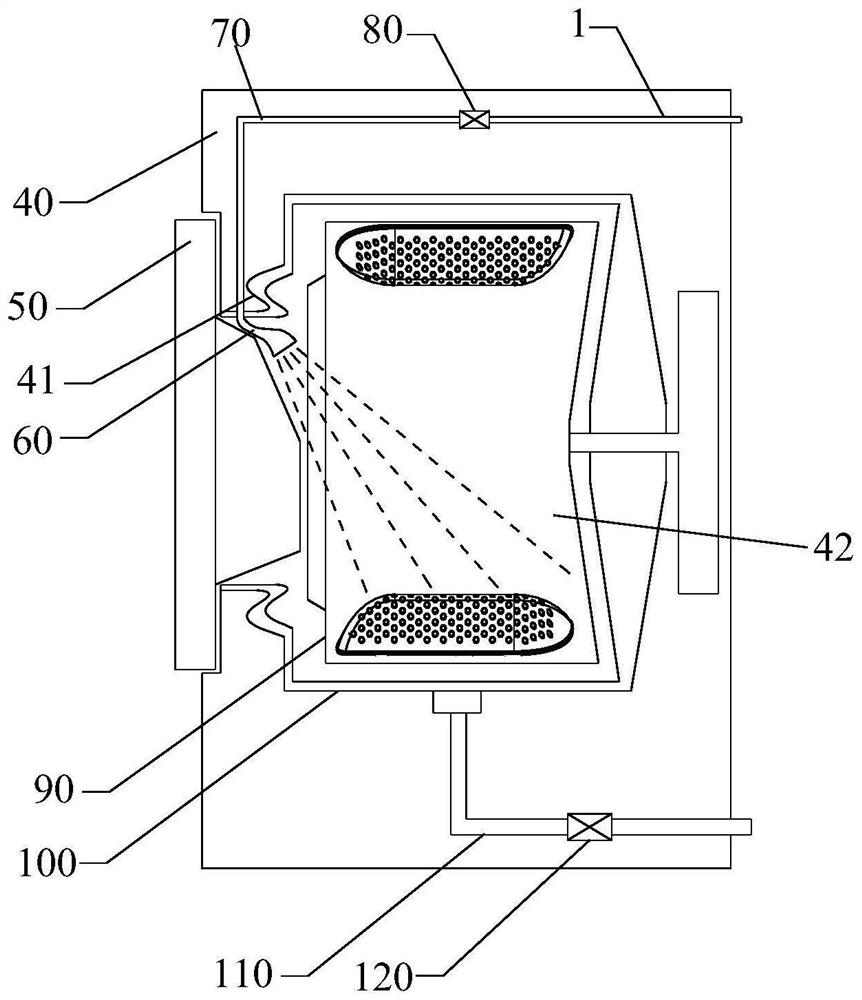

A spray head and spray nozzle technology, which is applied to washing machines with containers, other washing machines, rinsing equipment, etc., can solve the problems of limited coverage and difficult to completely cover the front and rear ends of the inner cylinder, so as to ensure the flushing force and guarantee Uniform distribution, good rinsing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

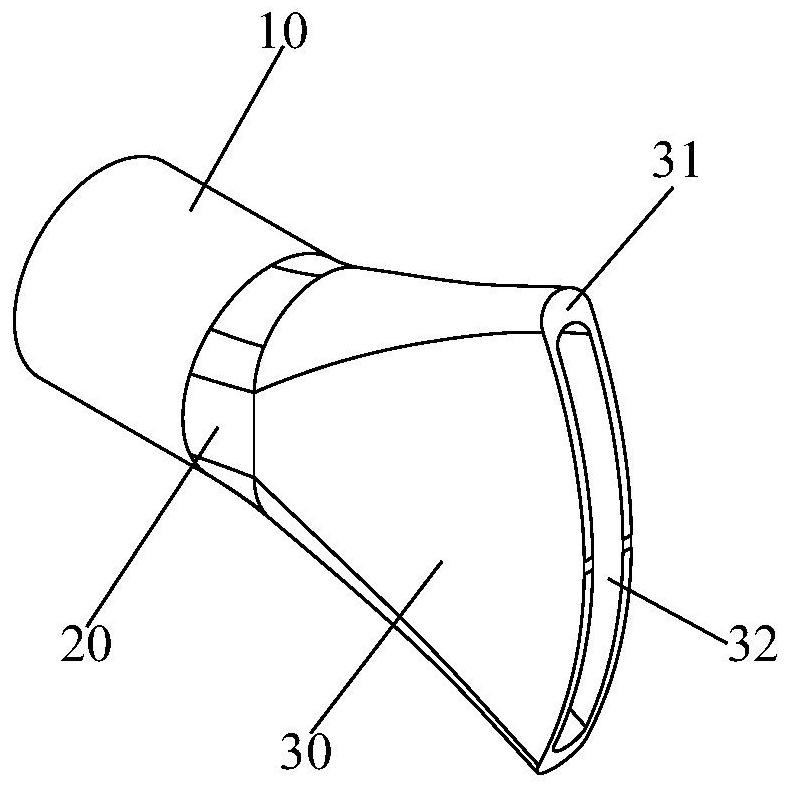

[0041] Such as Figure 3 to Figure 6As shown, the flared shower head includes a connecting pipe section 10, an intermediate pipe section 20 and a shrinking pipe section 30. The connecting pipe section 10 is used to connect with the water supply pipeline 1; 30 connection, the shrinkage pipe section 30 expands in the first direction and shrinks in the second direction along the direction away from the middle pipe section 20, and the first direction and the second direction are perpendicular to each other; wherein, the two end points of the shrinkage pipe section 30 in the first direction Points B and C respectively, the distance AE from any point A on the middle pipe section 20 to any point on the spray surface 31 of the shrink pipe section 30 is greater than the vertical distance from point A to point B and point C on the middle pipe section 20 AD.

[0042] Using the flaring spray head in this application can effectively avoid the blind area of the glass bowl through the con...

Embodiment 2

[0057] It should be noted that the difference between this embodiment and Embodiment 1 is that, as Figure 7 As shown, the spray surface 31 includes a BE1 plane segment, an E1E2 straight line segment and a CE2 straight line segment.

Embodiment 3

[0059] It should be noted that the difference between this embodiment and Embodiment 1 is that, as Figure 8 As shown, the spray surface 31 includes a BE1 arc segment, an E1E2 straight line segment, and a CE2 arc segment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com