Cutter for cutting machine tool

A technology for cutting machine tools and tools, which is applied in the field of tool tools for machine tools to achieve the effect of ensuring the cutting effect and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

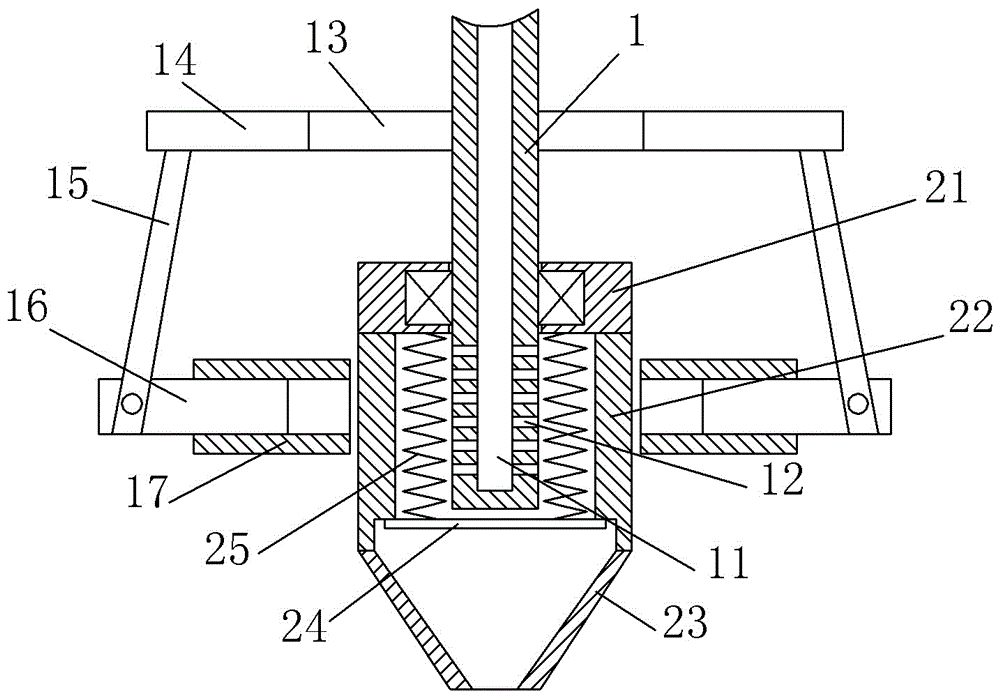

[0017] The reference signs in the drawings of the description include: rotating shaft 1, water inlet hole 11, drain port 12, driving gear 13, driven gear 14, connecting rod 15, pressing rod 16, chute 17, nozzle seat 21, elastic member 22 , Nozzle 23, pressing plate 24, extension spring 25.

[0018] The embodiment is basically as attached figure 1 Shown: a cutter for cutting machine tools, including a nozzle, the nozzle includes a nozzle seat 21, an elastic member 22 and a nozzle 23 from top to bottom, a working chamber is formed between the nozzle seat 21, nozzles 23 and the elastic member 22, and the elastic A first groove is also provided on the part 22, and a pressing plate 24 is arranged in the first groove, and the axial width of the pressing plate 24 is smaller than the axial width of the first groove, and the pressing plate 24 divides the working chamber into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com