High-sealing booster pump with sealing assembly

A sealing component and high-sealing technology, applied in the direction of pumps, pumps, connecting components, etc. with flexible working elements, can solve the problems of poor sealing effect of booster pumps, easy wear of gaskets, damage to motors, etc., to ensure the booster effect. , to avoid the effect of sealing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

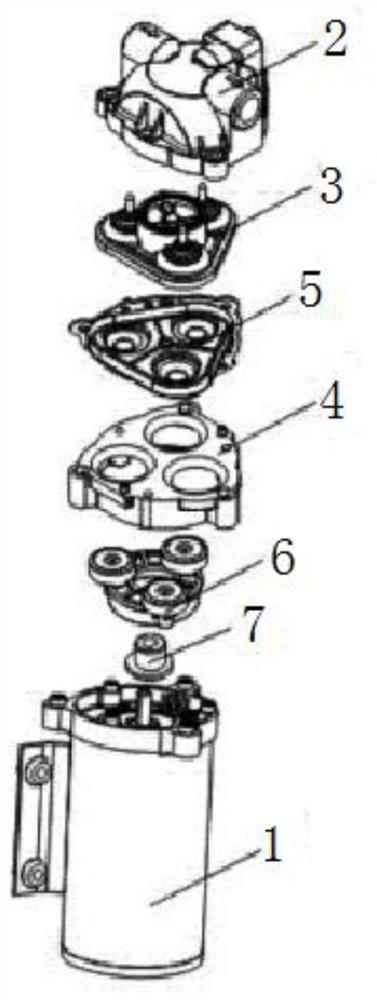

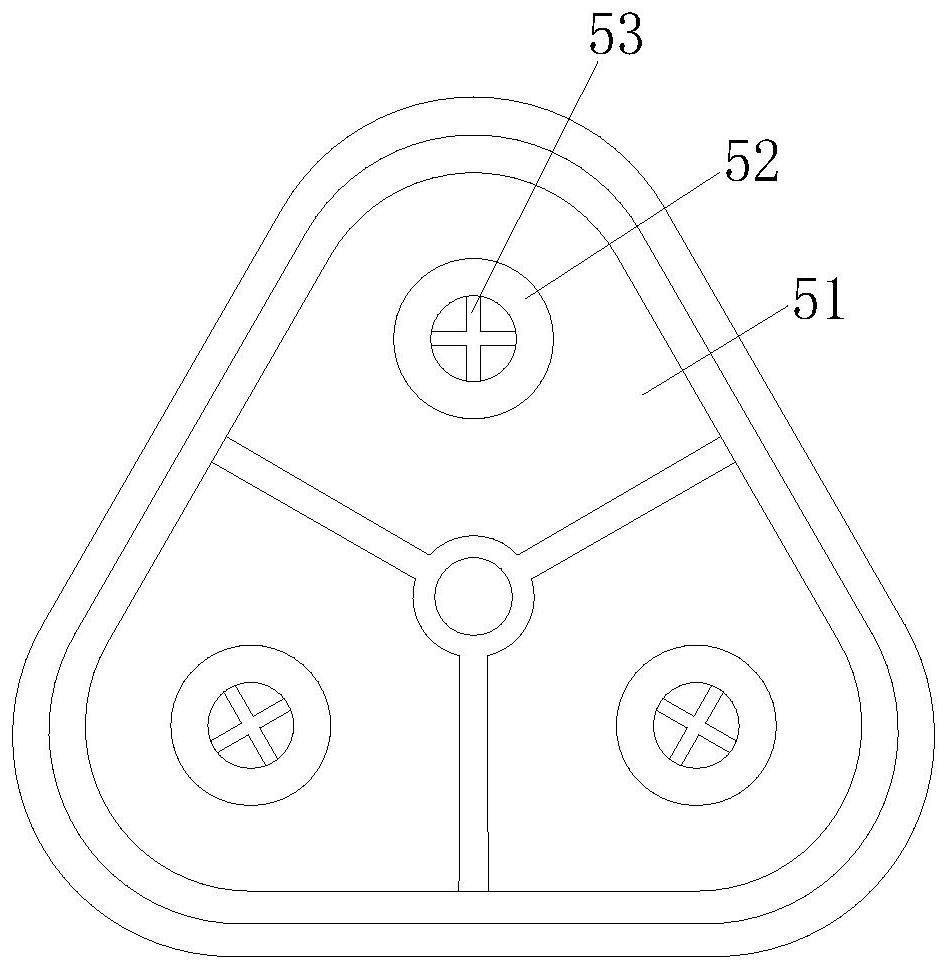

[0022] Embodiment 1, referring to the accompanying drawings, a high-sealing booster pump with a sealing assembly, including a motor 1 and a pump body part, the pump body part includes a front pump body 2, a pressure plate assembly 3, a rear pump body 4, and a diaphragm assembly 5 , a diaphragm seat 6 and an eccentric sleeve 7; the diaphragm assembly 5 includes a diaphragm 51 and a piston push block 52; the diaphragm 51 and the piston push block 52 are fixed together by bolts 53;

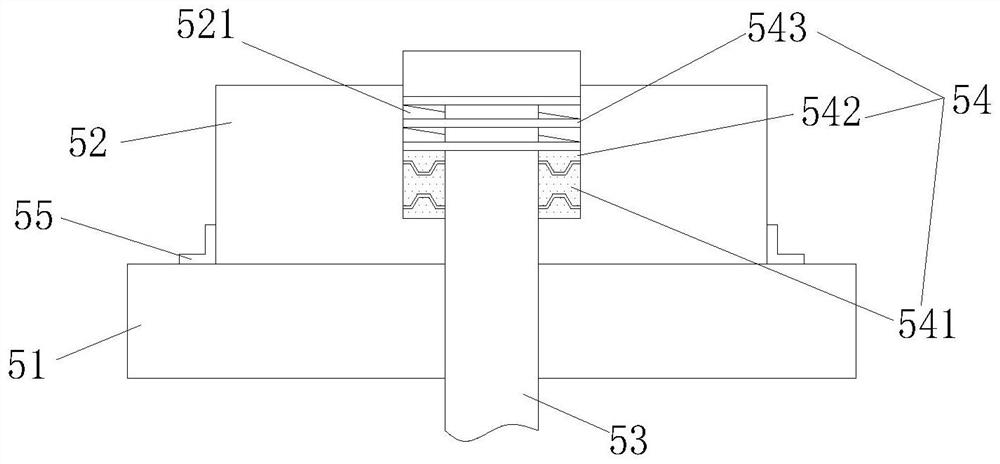

[0023] A sealing assembly 54 is arranged between the bolt 53 and the piston push block 52; the sealing assembly 54 includes a gasket 541, an extrusion part 542 and an elastic part 543; the gasket 541 is sleeved on the bolt 53; the The gasket 541 is provided with a squeezing gap 5411; the squeezing member 542 squeezes the squeezing gap 5411 to drive the elastic member 543 to radially expand; the elastic member 543 is in a contracted state, and continuously squeezes the squeezing member 542. pressure; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com