Spraying head with different spraying angles and washing machine

A technology with different angles and spray heads, which is applied to washing machines with containers, other washing machines, rinsing equipment, etc., can solve the problems of complete coverage of the front and rear ends of the inner cylinder, limited spray coverage, etc., to reduce clothing wear and tear. Deformation, guaranteed spray coverage area, good rinsing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

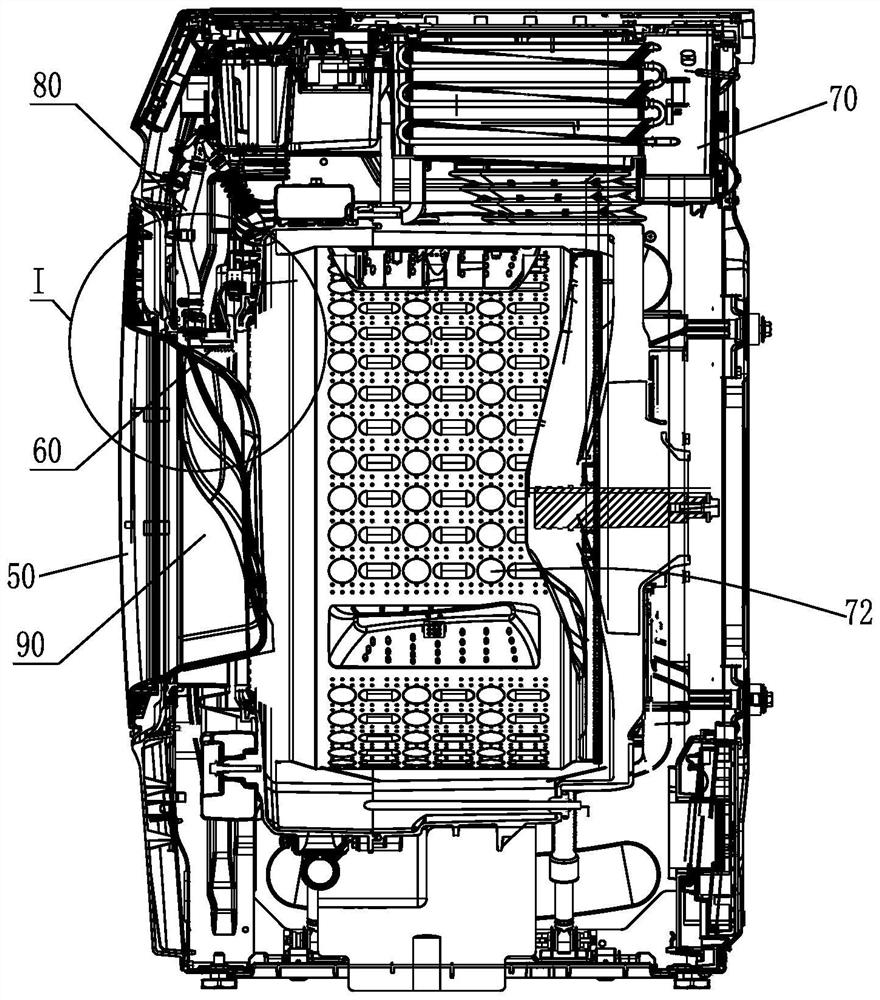

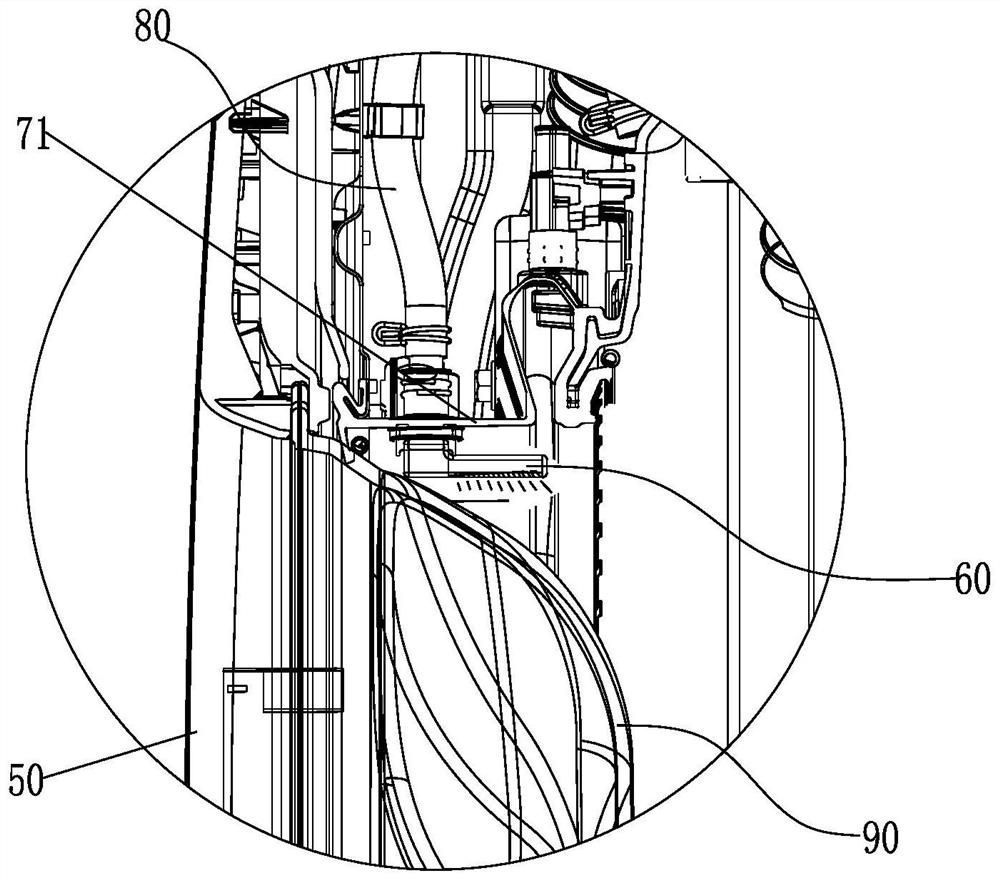

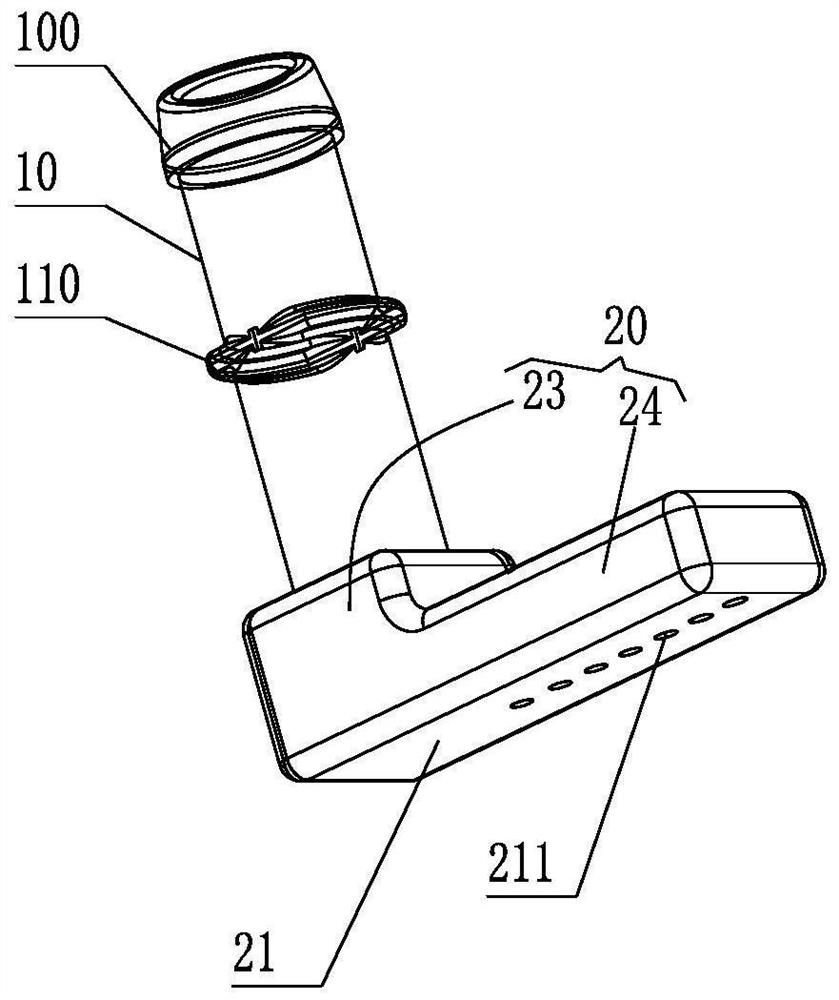

[0042] like Figure 3 to Figure 8 As shown, the sprinkler heads with different spray angles include a connecting pipe section 10 and a water spray structure 20, the connecting pipe section 10 is used to connect with the water supply pipeline; one end of the water spray structure 20 is connected with the connecting pipe section 10, and the water spray structure 20 has a spray The spray surface 21, the water spray structure 20 has a plurality of spray channels 22, and the plurality of spray channels 22 all extend to the spray surface 21 and have a plurality of spray holes 211 arranged at intervals at the spray surface 21; wherein, There is an included angle A between one end of the plurality of spray channels 22 communicating with the spray surface 21 and the spray surface 21 , and the included angle A gradually increases in the direction X away from the connecting pipe section 10 .

[0043] Using the spray heads with different spray angles in the present application can effecti...

Embodiment 2

[0073] It should be noted that the difference between this embodiment and the first embodiment is that, for example, Figure 9 to Figure 11 As shown, the shower head further includes a plurality of nozzles 30, the nozzles 30 are arranged on the spray surface 21, the plurality of nozzles 30 are arranged in a one-to-one correspondence with the plurality of spray holes 211, and each nozzle 30 corresponds to each corresponding spray The holes 211 communicate with each other, and the nozzles 30 extend along the extending direction of the corresponding spray channel 22 .

[0074] Optionally, the nozzle 30 is integrally formed with the water spray structure 20 .

[0075] Optionally, the distance between the nozzle 30 and the spray surface 21 is L, where 0.5mm≤L≤2mm. In this way, the direction of the water jet can be better guided, thereby ensuring the angle and range of the spray.

[0076] like Figure 3 to Figure 11 As shown, the connecting pipe section 10 of the sprinkler head 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com