Visual detection method for poses and apertures of coplanar equal-size multi-pore workpieces

A visual inspection and workpiece technology, applied in photogrammetry/video surveying, measuring devices, surveying and navigation, etc., can solve the problems of difficult maintenance, uncontrollable rise in cost, and high cost of visual inspection systems, and achieve high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to better understand the present invention, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

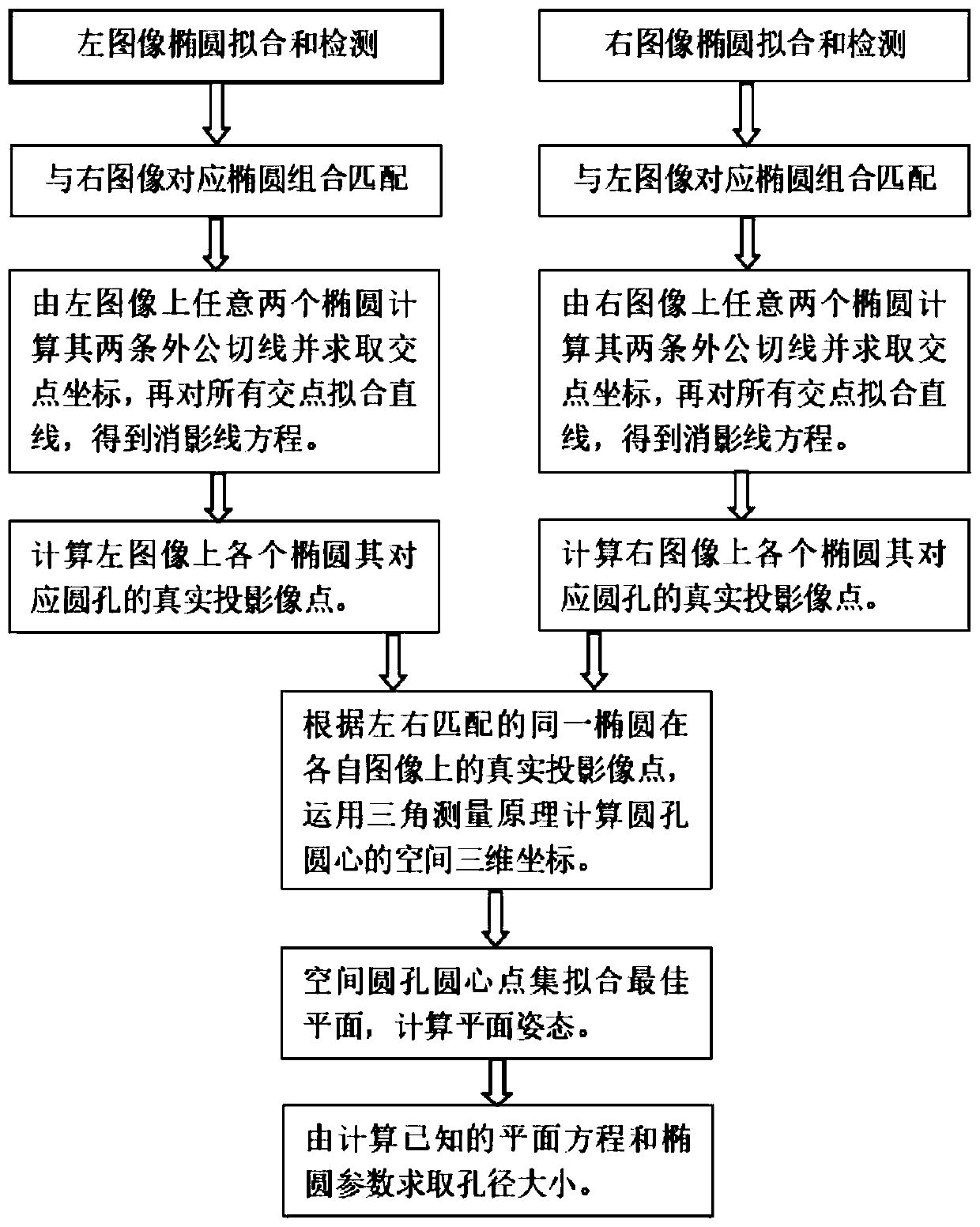

[0053] Such as figure 2 , the implementation steps of the embodiment of the present invention are described in detail below:

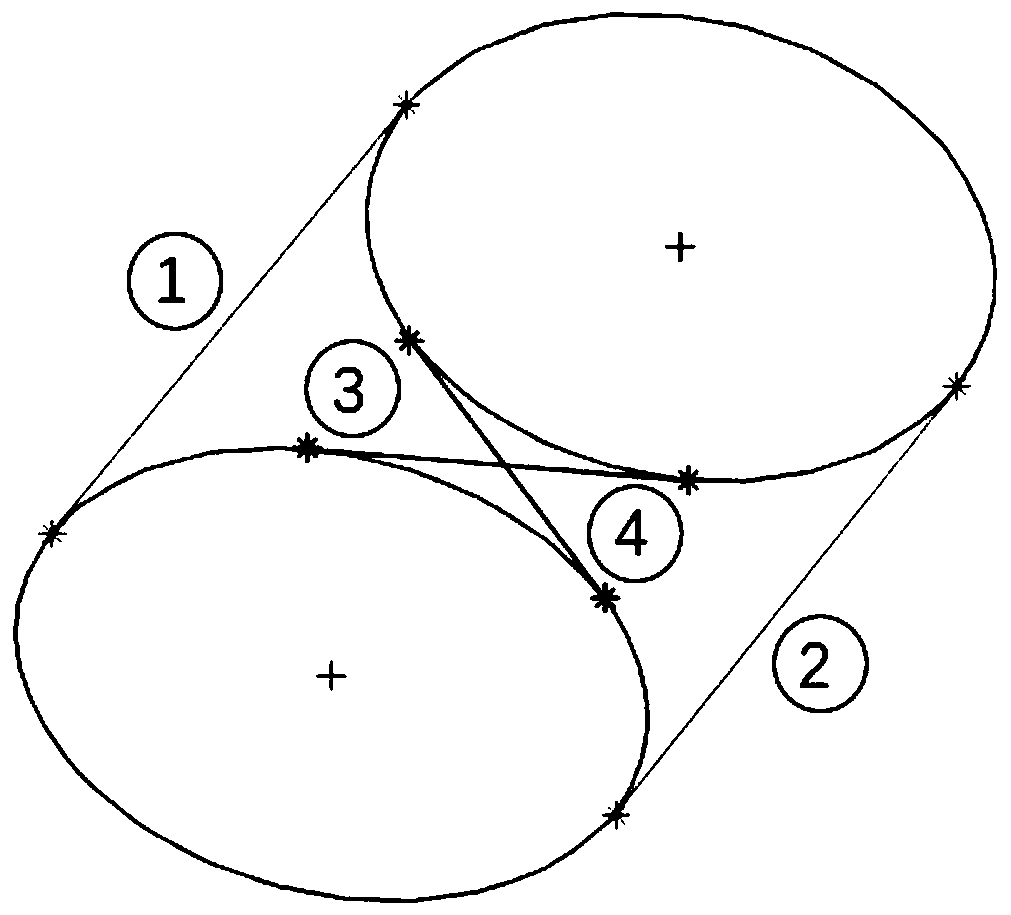

[0054] 1. Two cameras whose optical axes are parallel to each other are placed on the same horizontal plane at intervals. Firstly, the two cameras are calibrated respectively. After the calibration is completed, the two cameras respectively constitute the left and right cameras in the binocular vision measurement system. The surface porous workpiece is placed in the public field of view of the binocular camera, and the coplanar porous workpiece to be tested is as follows: figure 1 As shown, the workpiece can be photographed by both the left camera and the right camera, and the left and right cameras simultaneously photograph the workpiece to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com