A kind of hardenability measurement component and measurement method of medium and low hardenability steel

A measuring method and technology for measuring components, which are applied to measuring devices, analyzing materials, testing crystals, etc., can solve the problems of difficulty in ensuring consistent sample quenching conditions and large sample size, and reduce time and material costs, and achieve consistent quenching conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

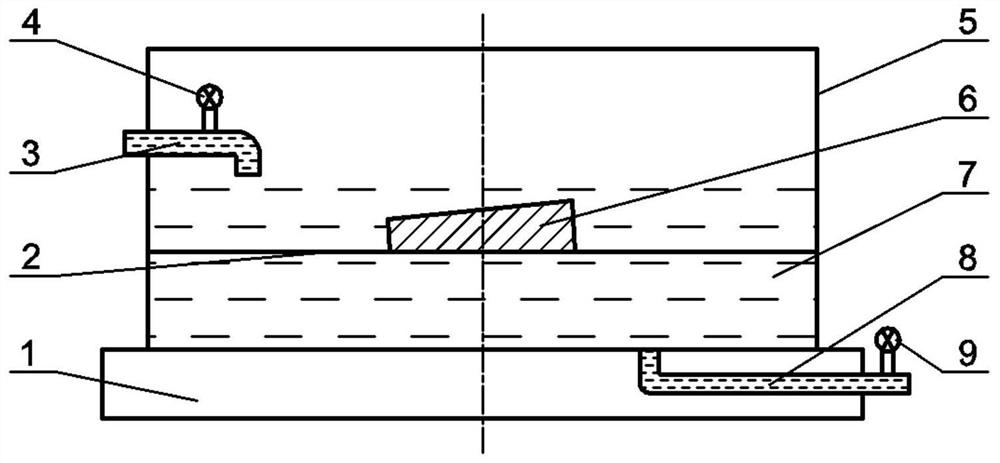

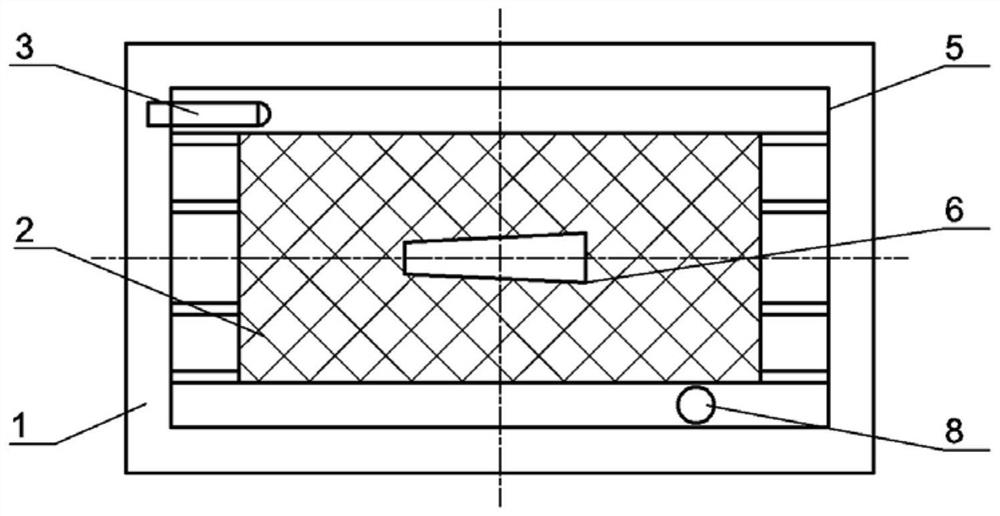

[0036] Example 1: from Figure 1~3 As shown, a medium-low hardenability steel hardenability measurement component includes a base 1, a bracket 2, a liquid inlet pipe 3, a liquid inlet valve 4, a liquid storage tank 5, a test sample 6, a quenching liquid 7, and a drain Pipe 8, drain valve 9,

[0037] The liquid storage tank 5 is fixedly arranged on the base 1, and the top side end of the liquid storage tank 5 is provided with a liquid inlet pipe 3 communicating with the cavity of the liquid storage tank 5, and the quenching liquid 7 is arranged in the liquid storage tank 5, and the liquid storage tank 5 The bottom end of the bottom is provided with a liquid discharge pipe 8 communicating with the cavity of the liquid storage tank 5, the liquid discharge pipe 8 is provided with a liquid discharge valve 9, and the bracket 2 is fixed horizontally on the inner wall of the lower part of the liquid storage tank 5;

[0038] The test sample 6 is set on the support 2;

[0039] Test sa...

Embodiment 2

[0051] Embodiment 2: This embodiment adopts the method for measuring the hardenability of the medium and low hardenability steel by the low hardenability steel hardenability measuring member in Embodiment 1, and the specific steps are as follows:

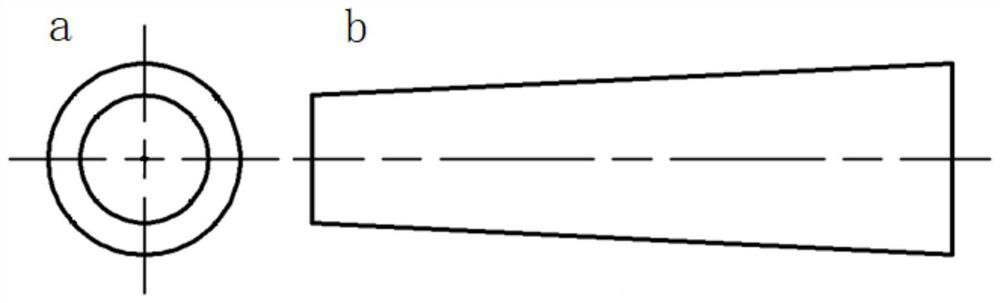

[0052] (1) The test sample of SA508-3 steel, which is a large nuclear power forging, is processed into an unequal diameter cone structure (see image 3 ), where the major diameter is Φ30mm, the minor diameter is Φ20mm, and the length is 100mm;

[0053] (2) Put the SA508-3 steel test sample with unequal diameter cone structure into a heat treatment furnace and heat it up to 900°C for 30 minutes, and keep it at 900°C for 30 minutes to make the sample completely austenitized. The heating process is as follows: Figure 5 shown;

[0054] (3) Fix the bracket horizontally on the inner wall of the liquid storage tank, open the liquid inlet valve of the liquid inlet pipe, and add the quenching liquid (water) into the liquid storage tank unt...

Embodiment 3

[0061] Embodiment 3: This embodiment adopts the method for measuring the hardenability of the medium and low hardenability steel by the low hardenability steel hardenability measuring member in Embodiment 1, and the specific steps are as follows:

[0062] (1) The test sample of SA508-3 steel, which is a large nuclear power forging, is processed into an unequal diameter cone structure (see image 3 ), where the major diameter is Φ30mm, the minor diameter is Φ20mm, and the length is 100mm;

[0063] (2) Put the SA508-3 steel test sample with unequal diameter cone structure into a heat treatment furnace and heat it up to 900°C for 30 minutes, and keep it at 900°C for 30 minutes to make the sample completely austenitized. The heating process is as follows: Figure 5 shown;

[0064] (3) Fix the bracket horizontally on the inner wall of the liquid storage tank, open the liquid inlet valve of the liquid inlet pipe, and add the quenching liquid (oil) into the liquid storage tank until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com