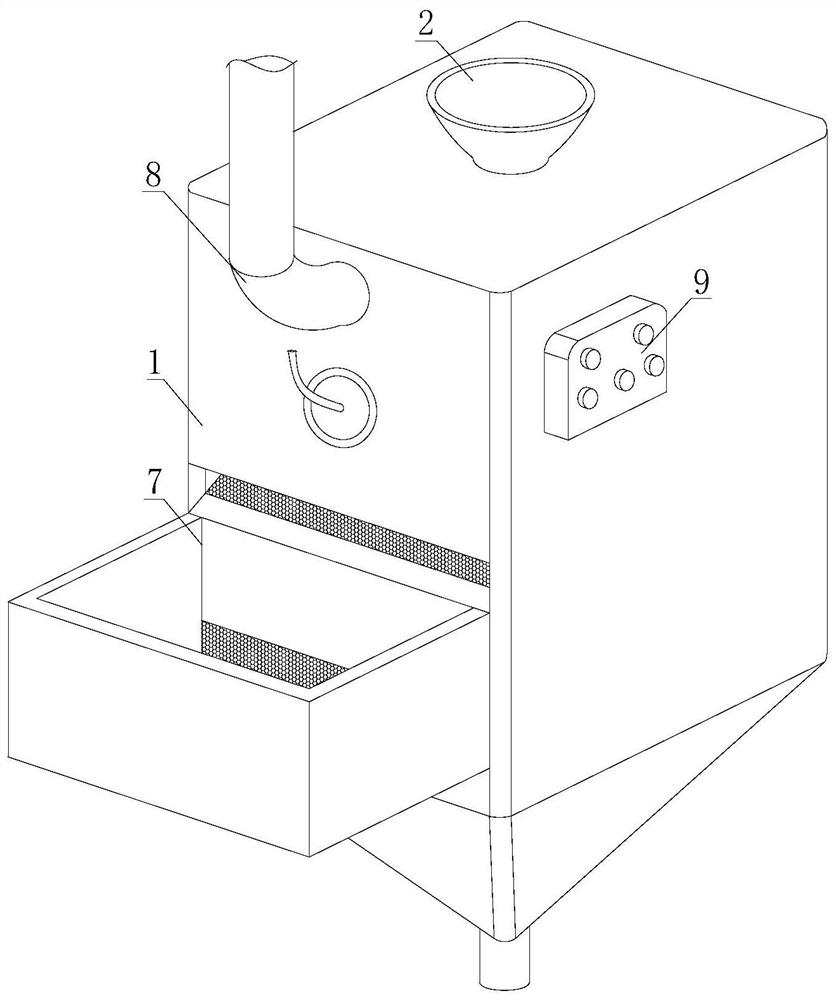

A quenching device for metal material processing and its implementation method

A technology of metal materials and quenching devices, which is applied in the direction of quenching devices, manufacturing tools, furnaces, etc., can solve problems such as uneven heating, reduced work efficiency, and easy burns, so as to reduce manual operation time, improve work efficiency, and avoid operation burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

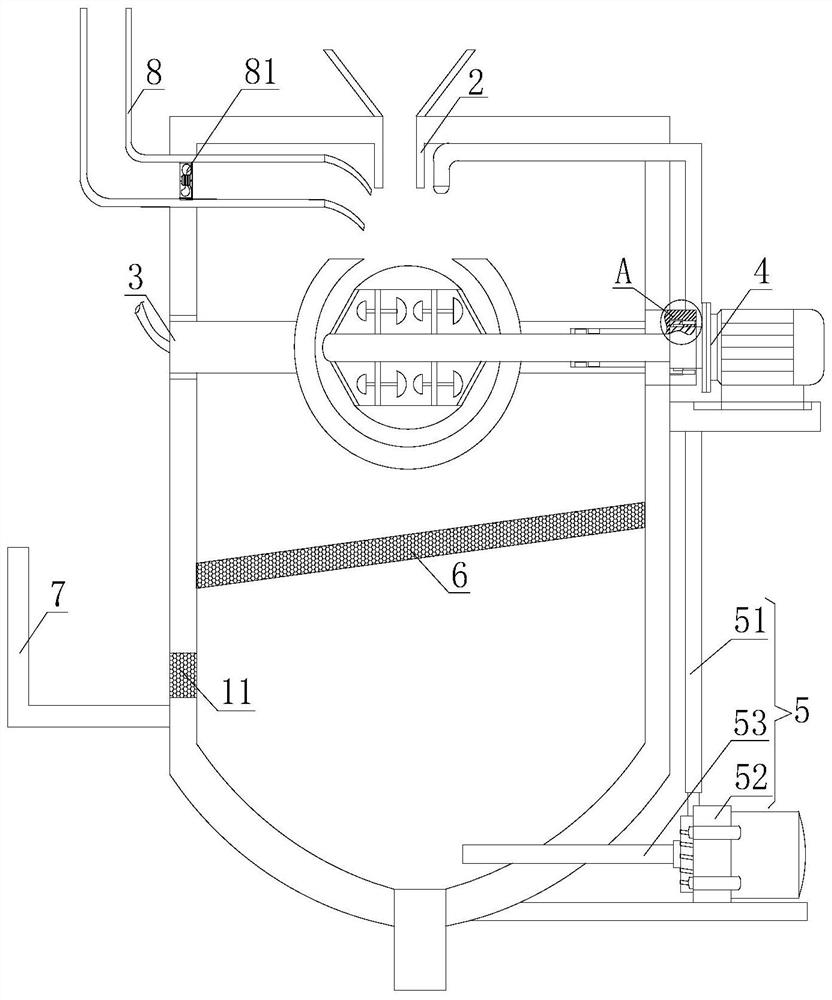

[0048] In order to better show the quenching process of the quenching device, the present embodiment now proposes an implementation method of a quenching device for metal material processing, including the following steps:

[0049] Step 1: Pour an appropriate amount of quenching liquid from the liquid flow hole 11 to the lower end of the inner cavity of the insulation shell 1, and turn on the heating mechanism 3 through the control panel 9 to preheat it;

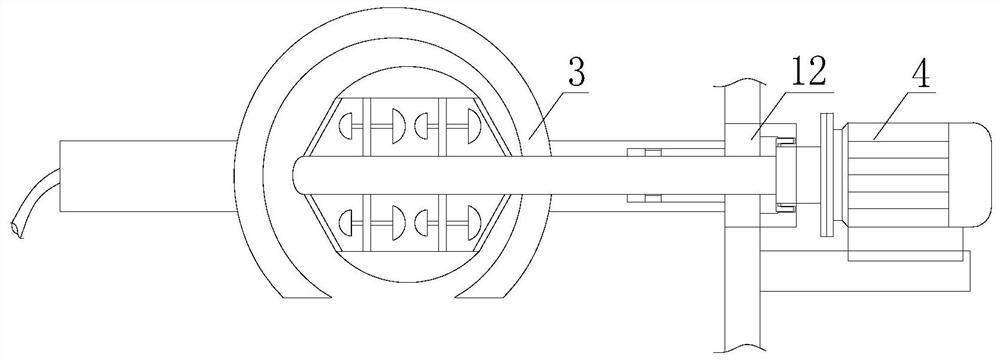

[0050] Step 2: Pour the metal material to be quenched into the feeding funnel 2, so that it flows into the insulating quenching material.

[0051] Inside the fireball 32, turn on the hood 81 and the servo motor 41 to stir the metal material evenly and slowly; Step 3: After the metal material is heated and quenched, turn off the servo motor 41 and turn on the small water pump

[0052] 52. Extract the quenching liquid and inject it into the interior of the insulating quenching ball 32;

[0053] Step 4: After the metal materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com