Method for manufacturing profiles by winding variable-section strips

A strip and cross-section technology, applied in the field of producing molding components, can solve the problem of unsuitable molding components, etc., and achieve the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

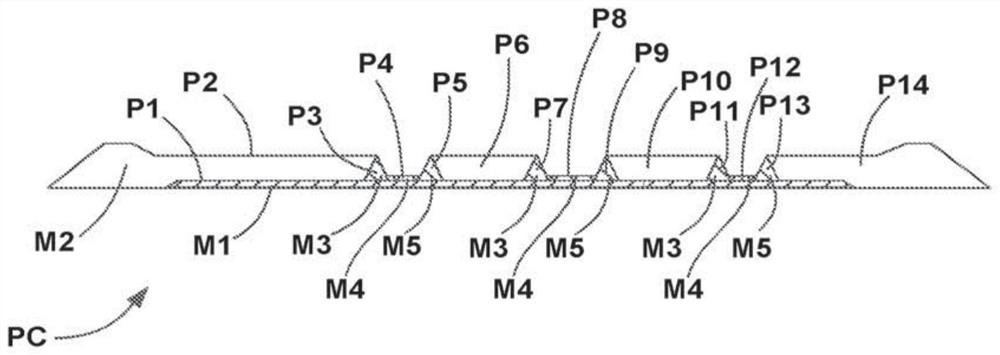

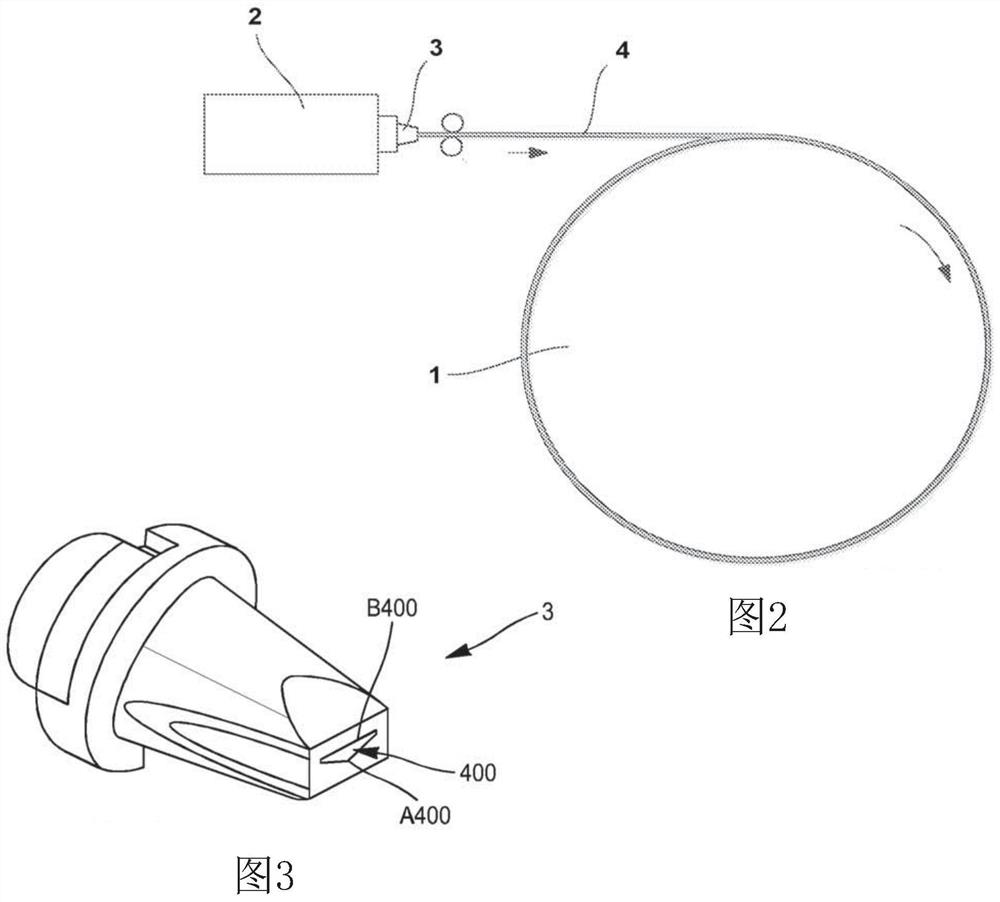

[0046] By way of example, a laying device for carrying out the method according to the invention comprises a forming drum rotated using a motorized assembly (not shown), and an extruder 2 leading to a nozzle 3, also as image 3 shown.

[0047] This assembly makes it possible to transport and wind the strip 4 on the forming drum 1 .

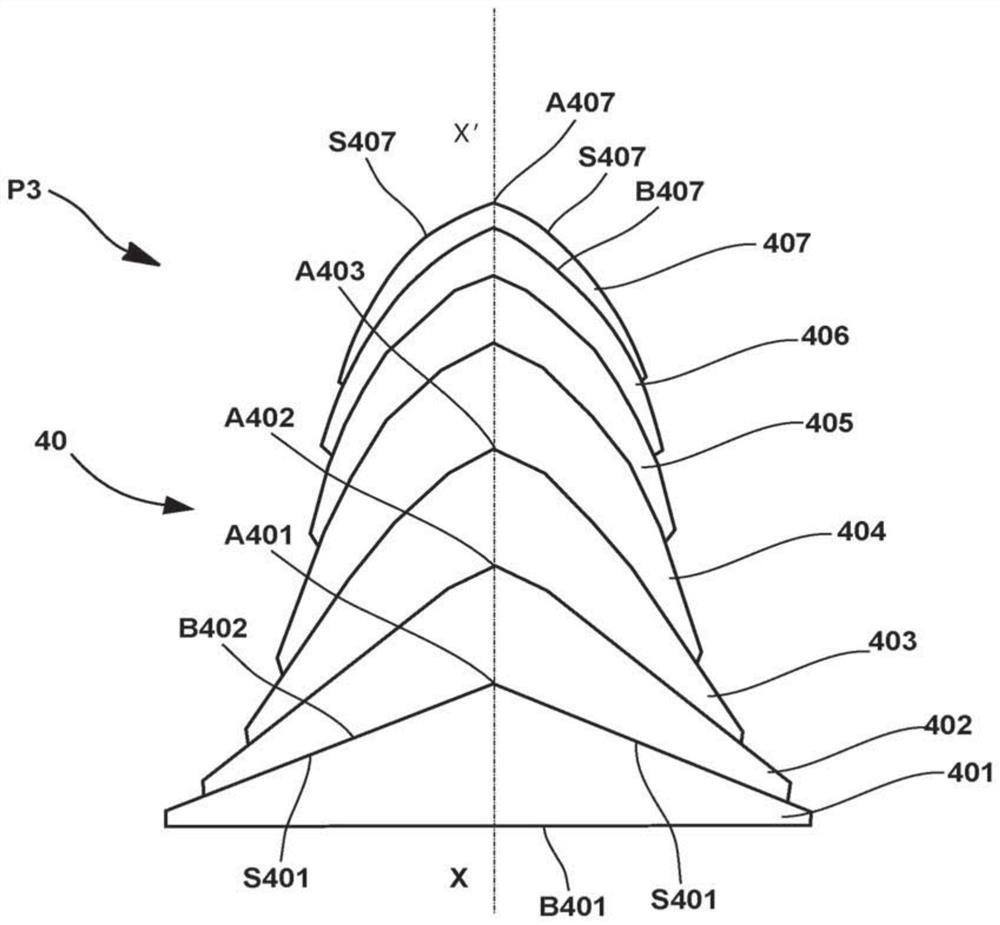

[0048] In step A, the strip 4 is fed. The profiles of the cross-sections 400, 410, 420, 430 of the strips are constant and known. In a particularly preferred manner, the strip is substantially triangular in cross-section, or even completely triangular, and preferably in the shape of an isosceles triangle.

[0049] As mentioned above, the triangular shape of the section makes it easier and faster to produce profiled element parts P3, P5, P7, P9, P11, P13, in particular essentially triangular profiled element parts, which are particularly stable.

[0050] More specifically, choosing an isosceles triangle shaped strip section advantageously gives ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com