Disposable stripping type self-destruction syringe

A syringe and peel-off technology, applied in the field of disposable peel-off self-destruct syringes, can solve the problems of infection risk, patient pain, and easy vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

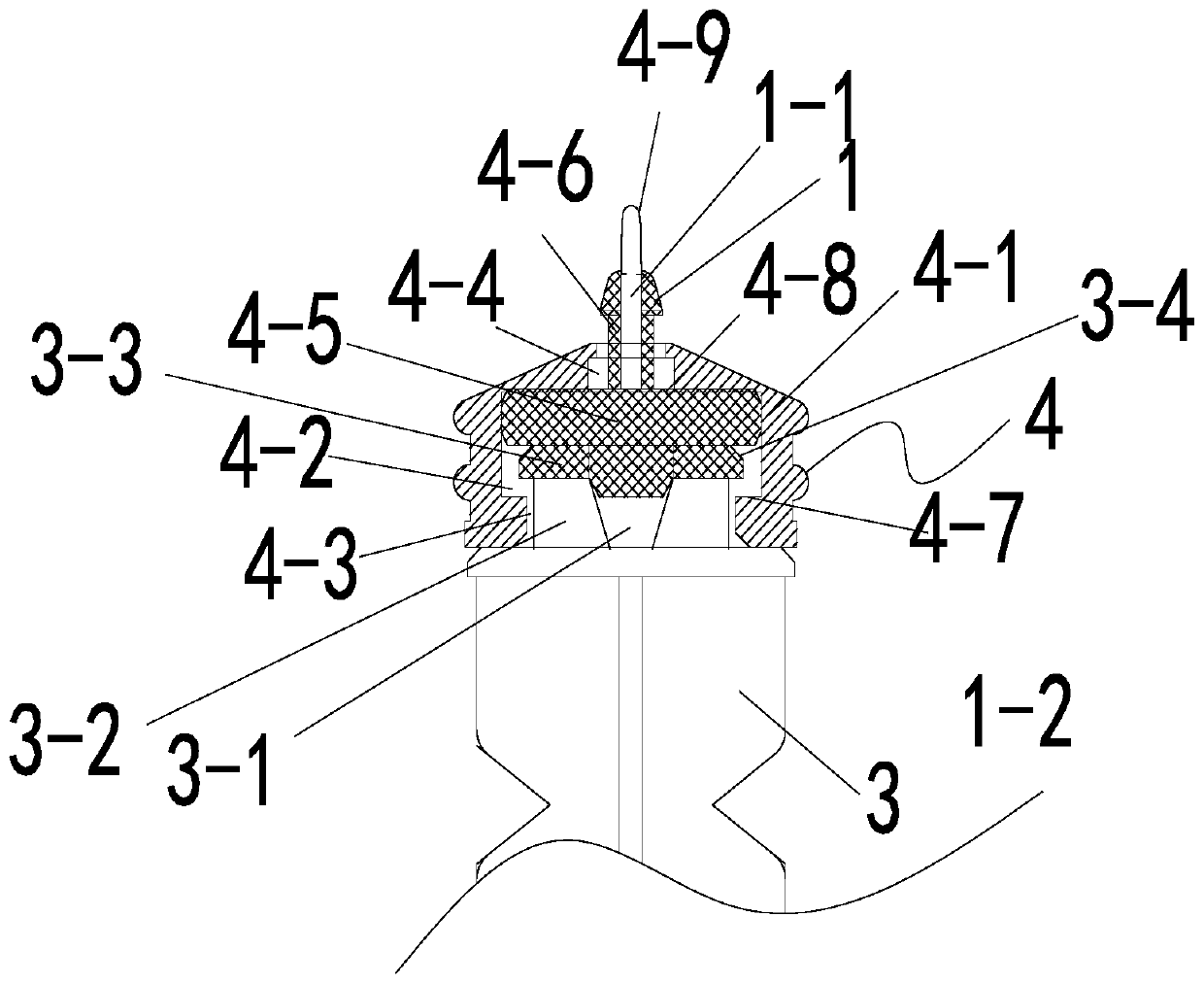

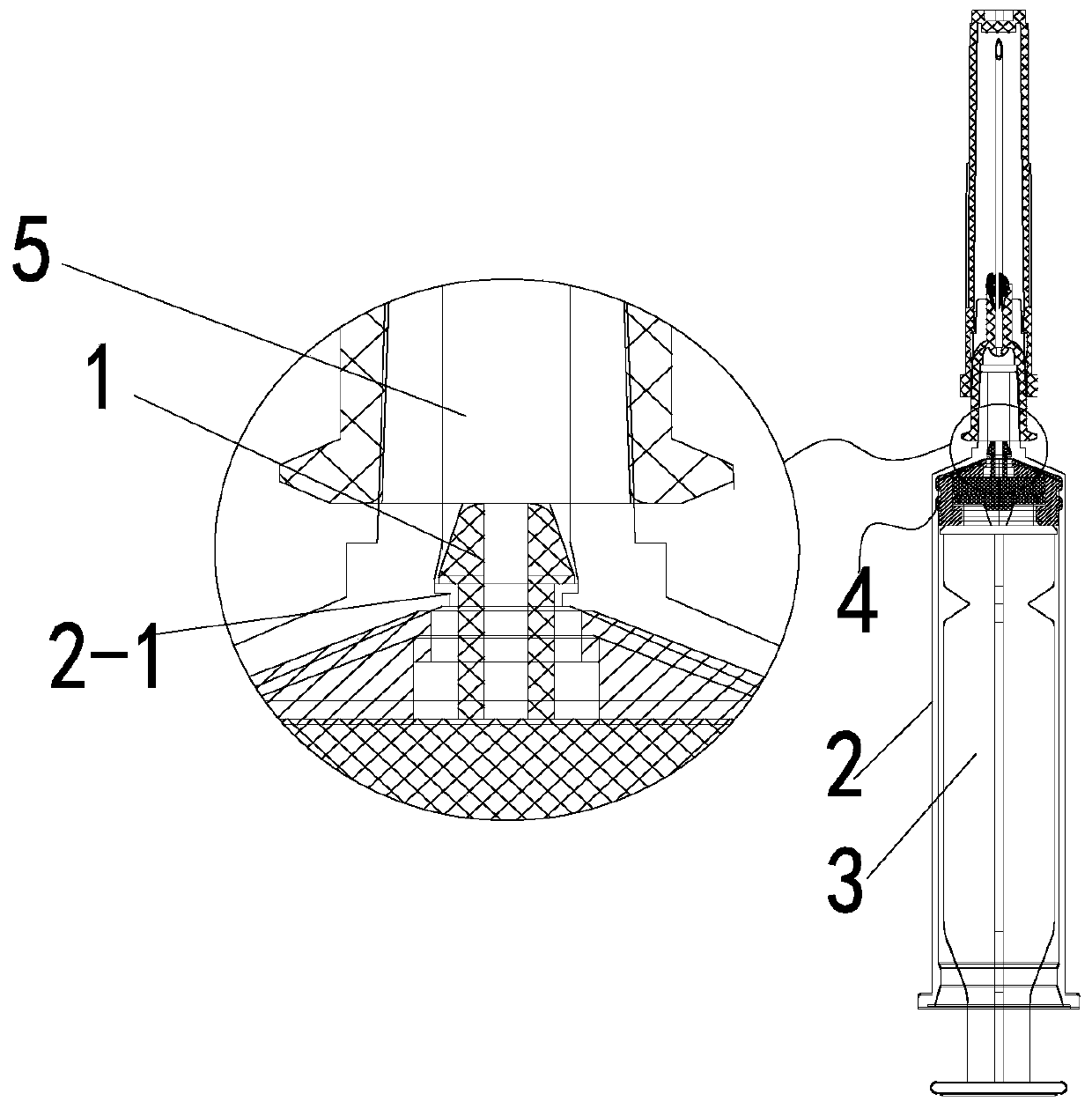

[0039] On the basis of Embodiment 1, in order to increase the locking performance of the tapered lock, the tapered lock 1 is formed with a locking maintenance mechanism. The specific locking maintenance mechanism is the connection block 4-9 that connects the top of the tapered lock 1 together or such as Figure 6 As shown, it includes a protrusion 4-10 protruding from the lower side of the tapered lock 1, and an annular locking strip 4-11 is formed on the protrusion of the annular protrusion 2-1 to cooperate with the protrusion 4-10.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap