Bending mechanism and operation method for intelligent carbon skateboard production convenient for rapid operation

A technology of rapid operation and bending mechanism, which is applied in the direction of storage devices, metal processing equipment, feeding devices, etc., can solve the problems of inconvenient movement and adjustment of support seats, reduction of finished carbon skateboards, and low efficiency, so as to save manual adjustment time, Effects that increase stability and facilitate quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

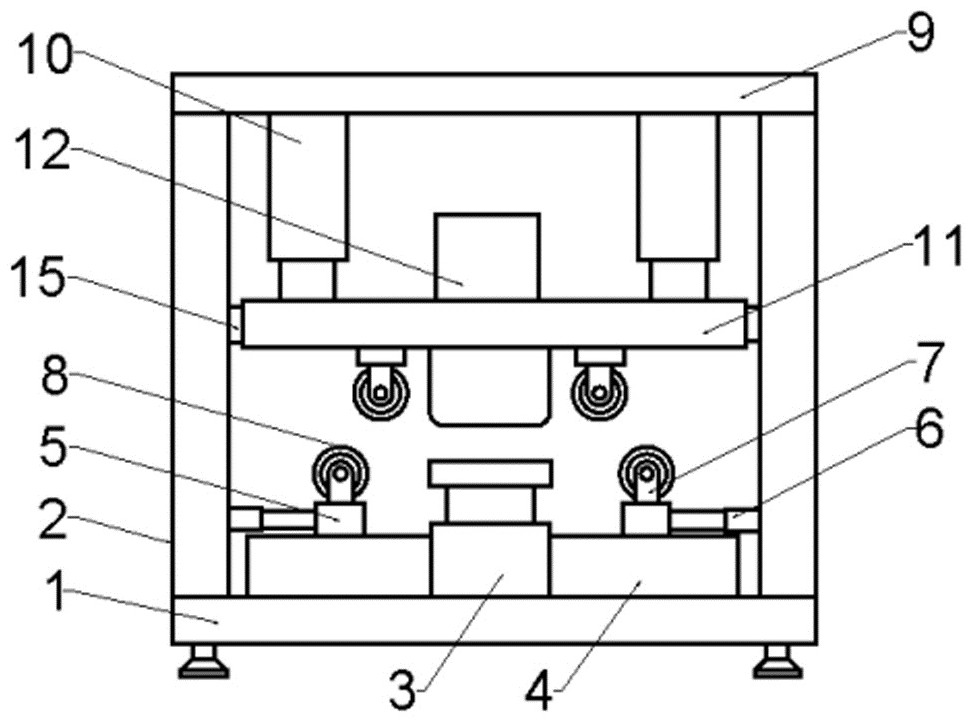

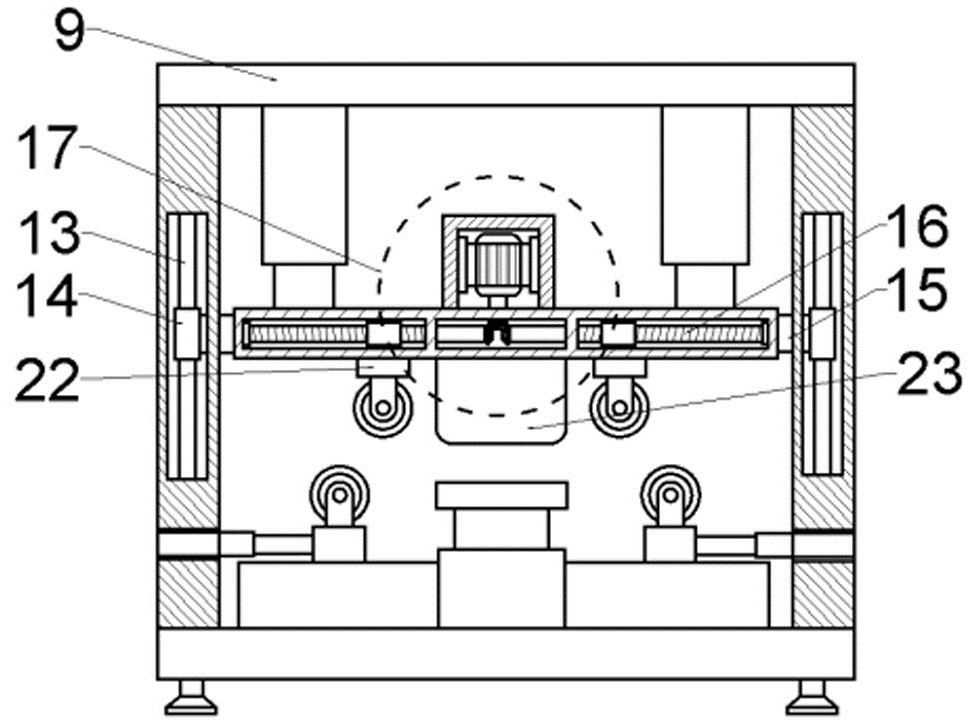

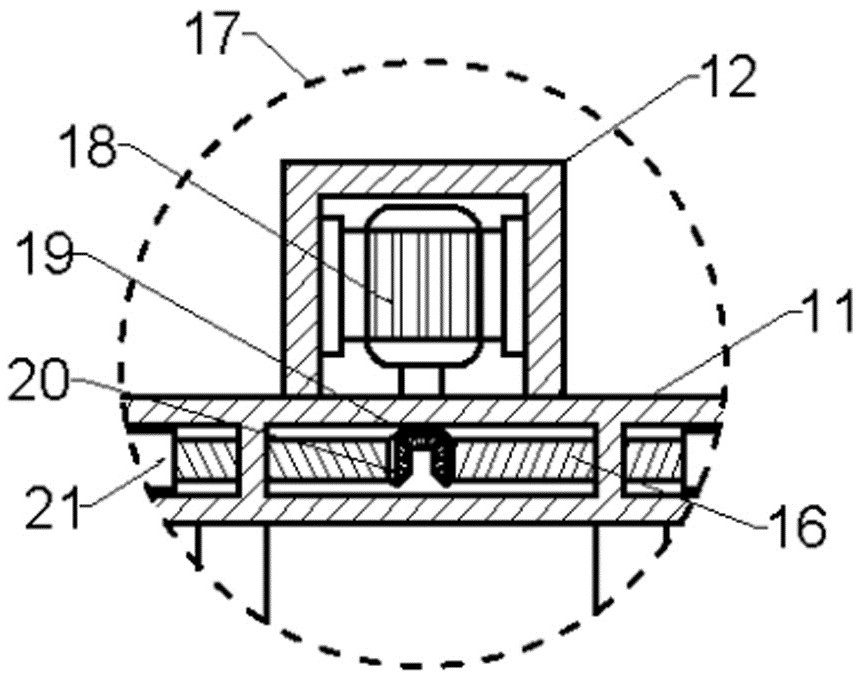

[0028] Embodiment 1: see Figure 1-6 , a bending mechanism for intelligent carbon skateboard production that is convenient for rapid operation, including a bearing seat 1, the bearing seat 1 is a rectangular plate-shaped horizontally arranged, and vertically installed on both sides of the top surface of the bearing seat 1. The support column 2 is fixed with a horizontally arranged pressure bearing platform 3 in the middle of the top surface of the bearing seat 1, and horizontally arranged pressure bearing plates 4 are arranged on both sides of the described pressure bearing platform 3, and each of the The bottom end of the pressure bearing plate 4 is fixedly connected with the top surface of the bearing seat 1; a circular mounting groove is horizontally opened on the inner side wall of each of the supporting columns 2, and a circular mounting groove is arranged in each of the mounting grooves. A telescopic rod 6 arranged horizontally is fixedly installed; a rectangular support...

Embodiment 2

[0032] Example 2: see Figure 7 , in the present embodiment, the present invention also proposes a bending mechanism for intelligent carbon skateboard production and an operation method thereof, which is convenient for quick operation, including the following steps:

[0033] Step 1: First, the telescopic rod 6, the cylinder 10 and the motor 18 are electrically connected to the external power supply through wires, and the staff places the bracket of the carbon skateboard on the top of the lower pressing block 34, and the two ends of the bracket are set on the lower pressing block 34. Roller 7, and then start to bend the bracket;

[0034] Step 2, according to the length of the carbon skateboard bracket, the staff drives the support block 5 to slide by controlling the expansion and contraction of the telescopic rod 6, and the T-shaped slider 28 at the bottom is moved to the T-shaped position on the top surface of the pressure plate 4 through the sliding of the support block 5. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com