3Ni-1.6Cr-0.5Mo submerged arc welding wire matched with steel for nuclear power equipment

A kind of equipment, nuclear power technology, applied in welding equipment, metal processing equipment, welding medium and other directions, can solve the problem that welding materials are not easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

[0020] Examples 1 and 2: According to the chemical composition of the welding wire in the present invention, two batches of welding wire steel were refined, the chemical composition of which is shown in Table 1, and drawn into φ4 submerged arc welding wire after annealing. Then apply the research and development welding wire and the nuclear-grade high-alkalinity low-hydrogen flux TYF-13HR for matching welding. The mechanical properties of the deposited metal are shown in Table 2 and Table 3.

[0021] Table 1 embodiment 1 and 2 welding wire chemical composition;

[0022] serial number C Si mn P S Cr Ni co Fe Example 1 0.10 0.12 1.60 ﹤0.005 0.002 1.65 3..69 ﹤0.01 margin Example 2 0.11 0.14 1.58 0.005 0.002 1.72 3.73 ﹤0.01 margin

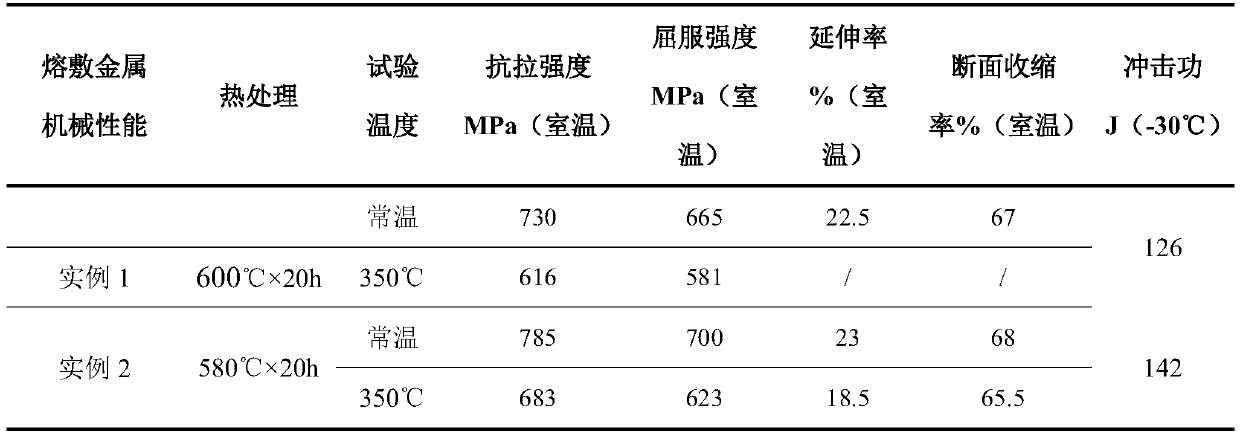

[0023] Table 2 embodiment 1 and 2 weld metal properties;

[0024]

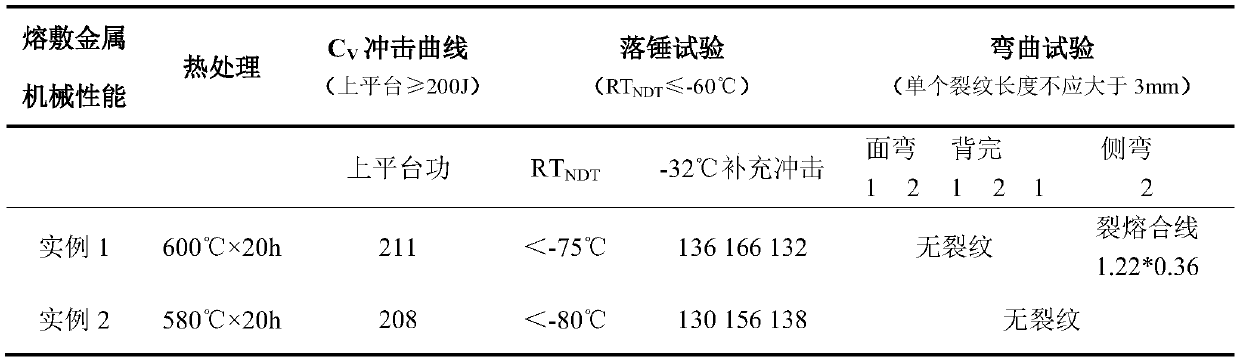

[0025] Table 3 Weld metal properties of Examples 1 and 2.

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com