A kind of welding wire for submerged arc automatic welding in nuclear-level strong irradiation area

A flux, low-hydrogen technology, used in welding media, welding equipment, welding equipment, etc., can solve problems such as high cost, dependence on imported welding wire, and difficult cycle control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

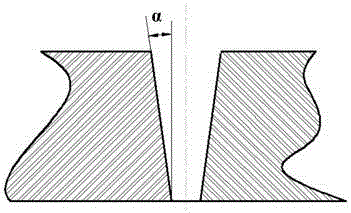

[0031] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention.

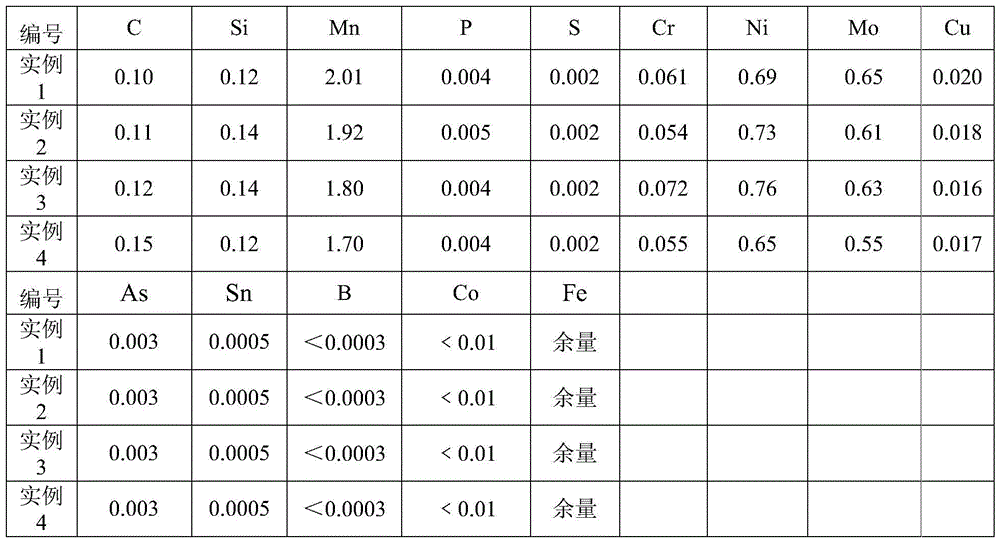

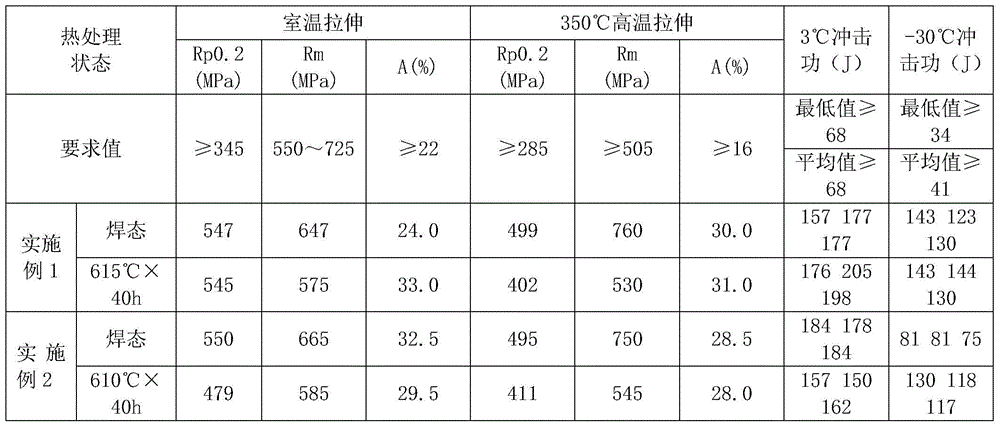

[0032] The present invention is based on the research and invention based on the technical requirements for the manufacture of third-generation nuclear power equipment, and discloses the chemical composition of a submerged arc welding wire. , P≤0.010, S≤0.010, Mo 0.45~0.65, Ni 0.60~0.80, Cr≤0.10, Cu≤0.020, Co≤0.020, B≤0.0005, As≤0.005, Sn≤0.005, and the balance is Fe Avoid impurities. According to the chemical composition of the welding wire in the present invention, two batches of welding wire steel were refined, the chemical composition of which is shown in Table 1, and drawn into φ4 submerged arc welding wire after annealing.

[0033] The assembly m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com