Encapsulation base plate

A technology for encapsulating substrates and circuit boards, which is applied to printed circuit components, electrical components, and electrical solid devices, and can solve problems such as warping and deformation of thinner substrates, smaller thickness of thinner substrates, and inability to meet the process. Achieve the effect of increasing strength, not easy to warp and deform, and improving bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

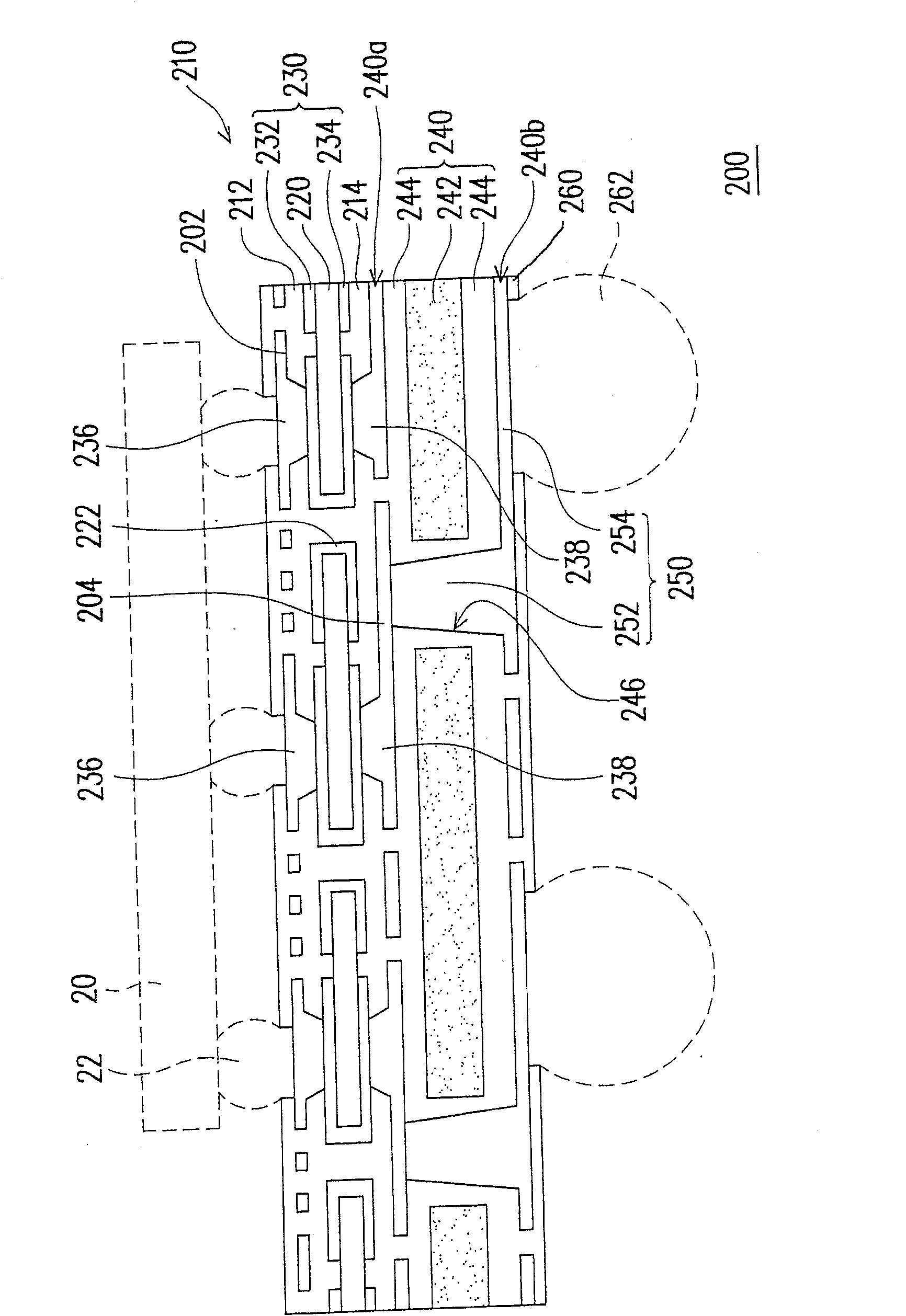

[0044] Please refer to figure 2 , which shows a schematic diagram of a package substrate according to an embodiment of the present invention. The packaging substrate 200 includes a circuit board 210 , which meets the circuit density and thickness restrictions required by the thinned substrate, so as to accelerate the transmission speed of electronic signals. The circuit board 210 has a plurality of upper contacts 202 (ie second contacts), which correspond to the bumps 22 on the connection chip 20 (indicated by dotted lines) to transmit electronic signals. In particular, the present invention uses the insulating layer 220 without glass fiber cloth and the metal layers on both surfaces to make the inner layer circuit 230, and the inner layer circuit 230 includes an upper layer circuit 232 and a lower layer circuit 234, which can be passed through the insulating layer. The plated through hole 222 of 220 is electrically connected. Wherein, the thickness of the insulating layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com