Easy-to-peel carrier foil as well as preparation method and application thereof

A carrier foil and easy peeling technology, which is applied in the manufacture of printed circuits, the manufacture of printed circuit precursors, electrical components, etc., can solve the problem that the carrier foil layer and the ultra-thin copper foil layer are partially peeled off, cannot be peeled off, and the peeling strength of the carrier foil is unstable. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention also discloses a method for preparing an easy-peelable carrier foil, which includes the following steps:

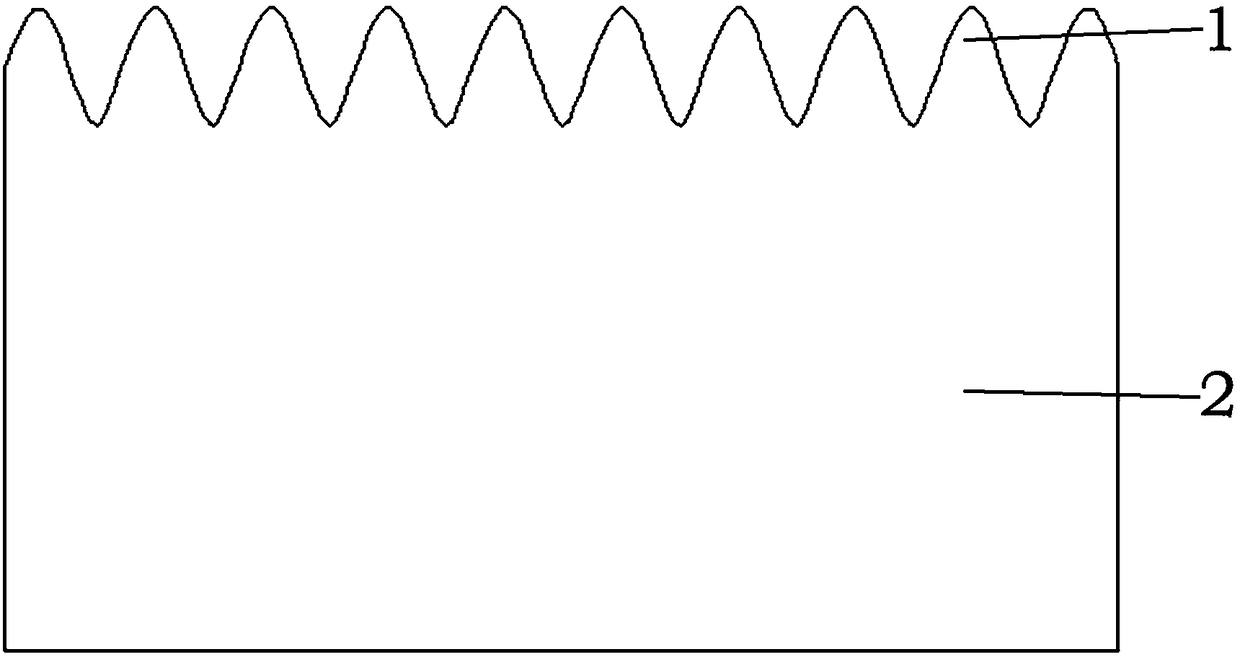

[0043]Step 1: roughening the surface of the carrier foil to obtain a roughened carrier foil 2;

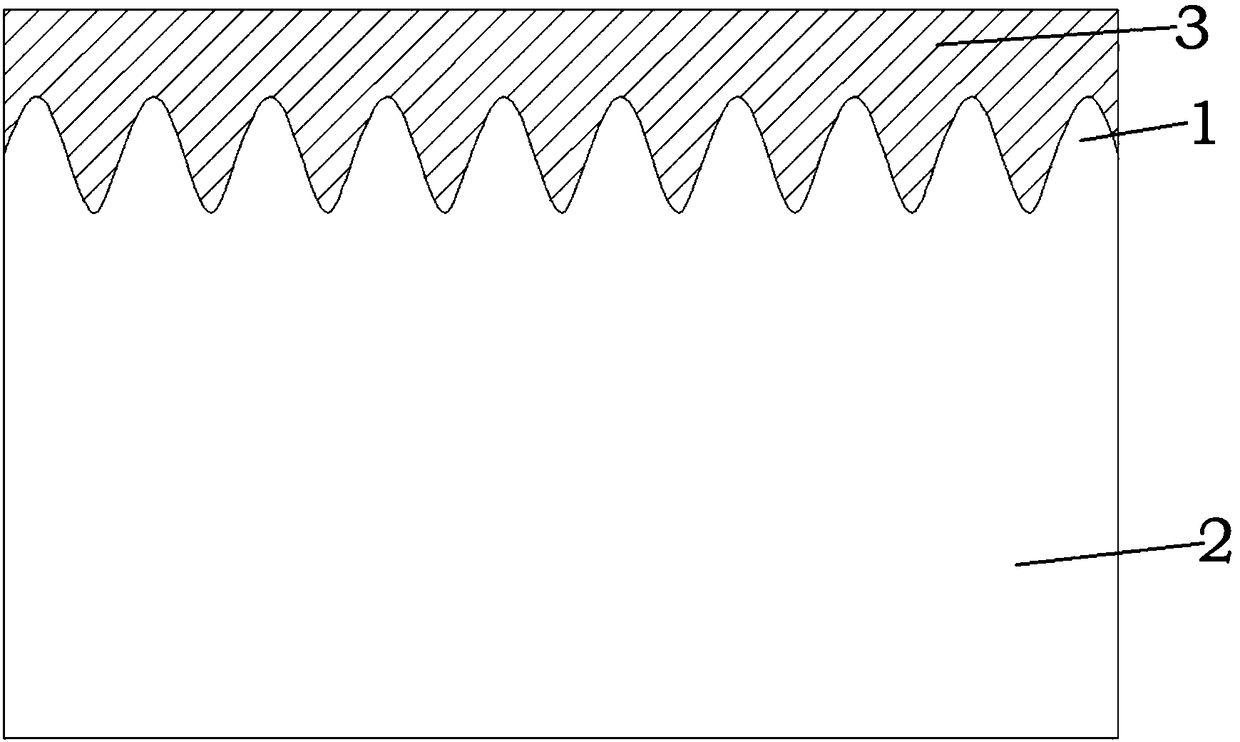

[0044] Step 2: Adhere to the graphite-like material 3 on the rough surface of the roughened carrier foil 2 by chemical vapor deposition or magnetron sputtering to obtain an easy-to-peel carrier foil.

[0045] Application of the easy-peelable carrier foil disclosed in the present invention or the easy-peelable carrier foil prepared by the above method for preparing the easy-peelable carrier foil in the preparation of ultra-thin copper foil.

[0046] Specifically, the above application includes the following steps:

[0047] Step 1: roughening the surface of the carrier foil to obtain a roughened carrier foil 2;

[0048] Step 2: attach graphite material 3 to the rough surface of the roughened carrier foil 2 to obtain an easy-to-peel carrier foil;

[0049] ...

Embodiment 1

[0055] The specific embodiment of the present invention provides a preparation method and application of an easy-peelable carrier foil. Example 1 includes the following steps:

[0056] Step 1: Take a piece of carrier copper foil with a thickness of 20 microns;

[0057] Step 2: forming a raised structure on the carrier copper foil by photochemical etching;

[0058] Step 3: Electroplate graphite on the surface of the raised structure of the carrier copper foil by CVD, and the graphite surface (the side away from the raised structure of the carrier copper foil) is smooth and flat;

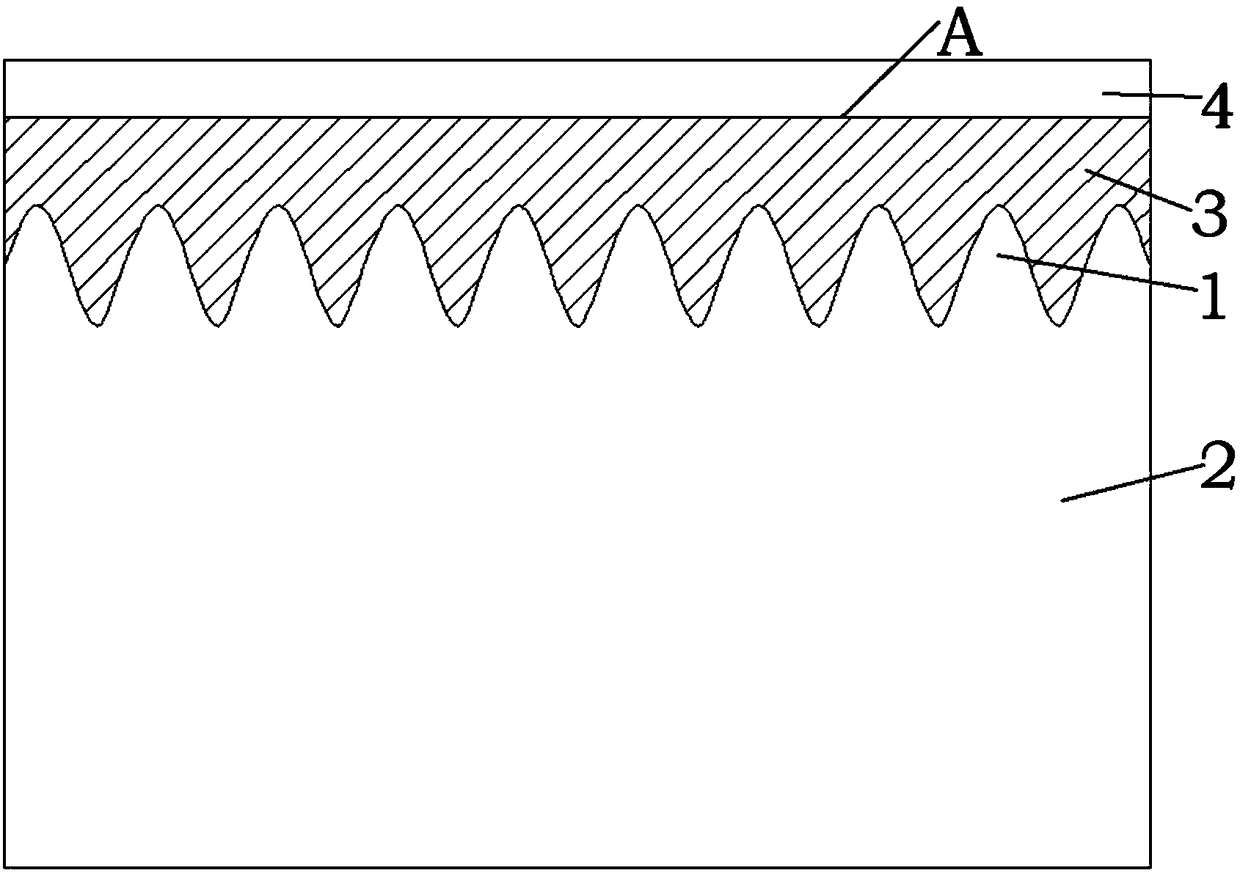

[0059] Step 4: Prepare an ultra-thin copper foil with a thickness of 2 microns by electroless plating on a smooth and flat graphite surface;

[0060] Step 5: hot pressing on the carrier copper foil by means of hot pressing, and completely peeling off the carrier copper foil and the ultra-thin copper foil.

[0061] Specifically, the graphite surface (the side away from the convex structure side of th...

Embodiment 2

[0063] The specific embodiment of the present invention provides a preparation method and application of an easy-peelable carrier foil, and embodiment 2 includes the following steps:

[0064] Step 1: Take a piece of carrier aluminum foil with a thickness of 25 microns;

[0065] Step 2: forming a raised structure on the carrier aluminum foil by photochemical etching;

[0066] Step 3: The surface of the raised structure of the carrier aluminum foil is coated with graphite by CVD, and the graphite surface (the side away from the raised structure of the carrier aluminum foil) is smooth and flat;

[0067] Step 4: Prepare an ultra-thin copper foil with a thickness of 3 microns by electroless plating on a smooth and flat graphite surface;

[0068] Step 5: hot pressing on the carrier aluminum foil by means of hot pressing, and completely peel off the carrier aluminum foil and the ultra-thin copper foil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com