Pull ring unlocking structure of optical module

An optical module, unlocking technology, applied in the field of optical communication, can solve the problem that the optical module is not easy to unlock and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

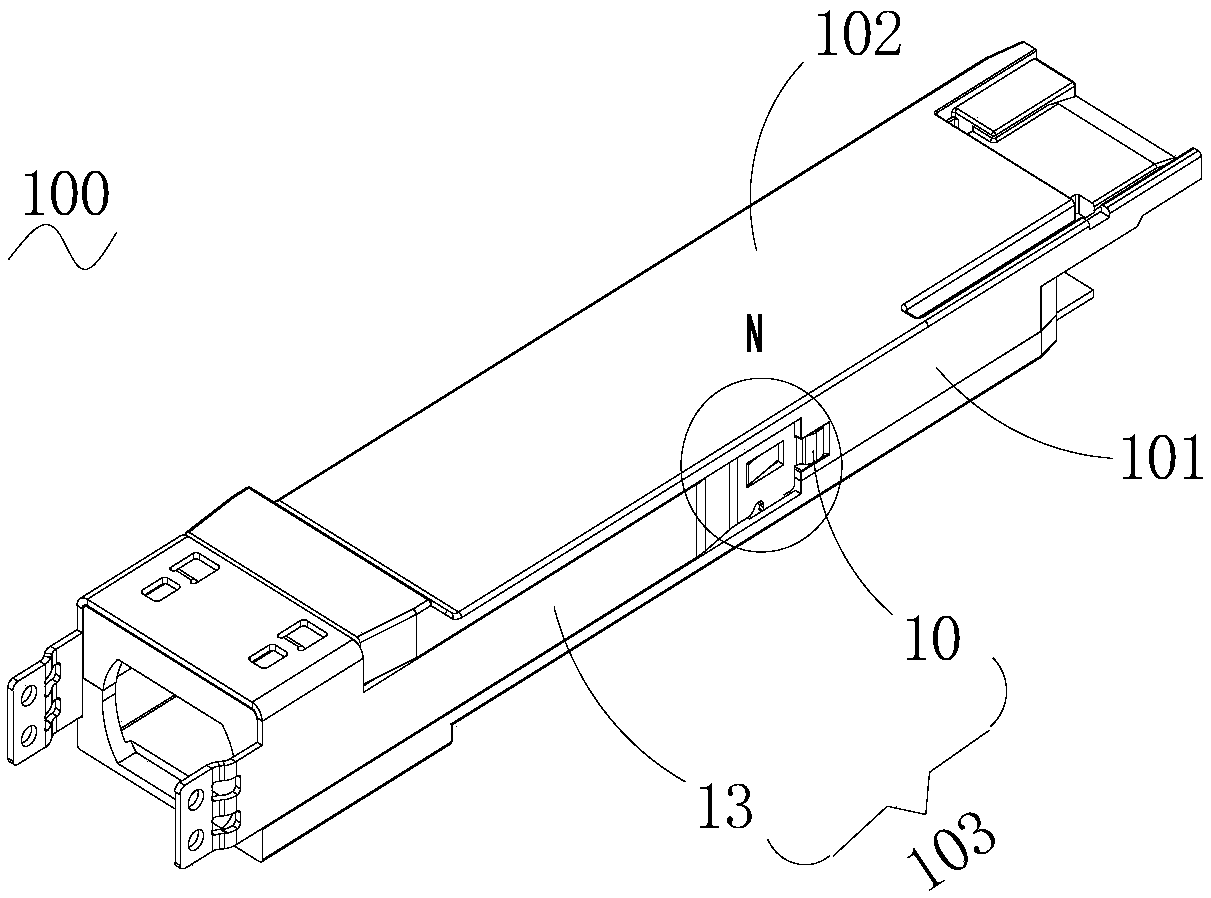

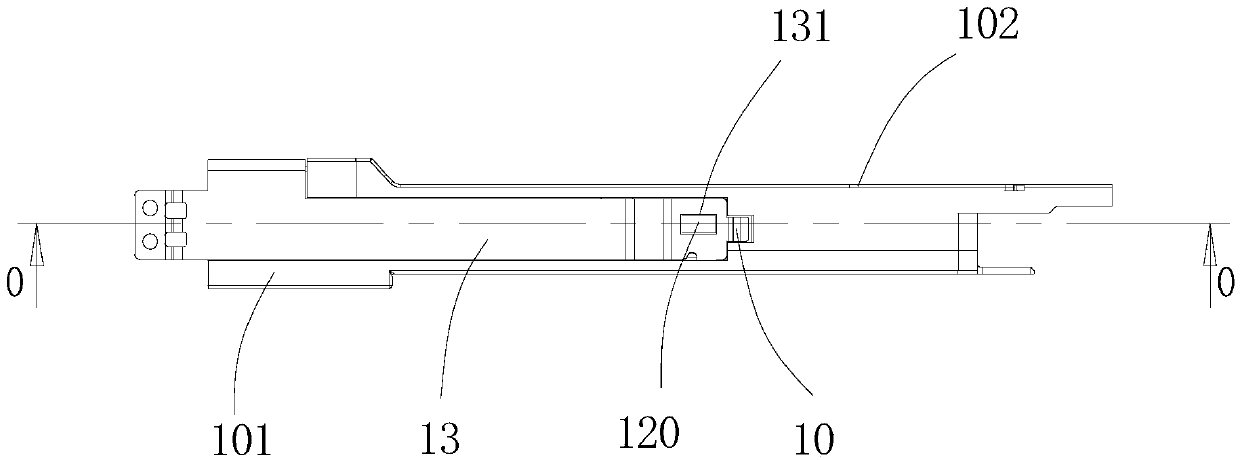

[0030] Please refer to figure 1 , figure 1 It is a three-dimensional view of an optical module. The optical module 100 of this embodiment includes a base 101 , an upper cover 102 and a pull ring 103 . The pull ring 103 is installed on the base 101, and the base 101 and the upper cover 102 are fixed and installed by screws. The pull ring 103 is composed of a tongue 10, a ring arm 13 and a handle (not shown). Both sides of the pull ring 103 are ring arms 13 , and the top end is integrally formed with the ring arm and has a bent tongue 10 , the width of the tongue 10 is smaller than that of the ring arm 13 . The tongue 10 and the ring arm 13 are integrally processed by metal material, and the handle can be made of soft rubber material.

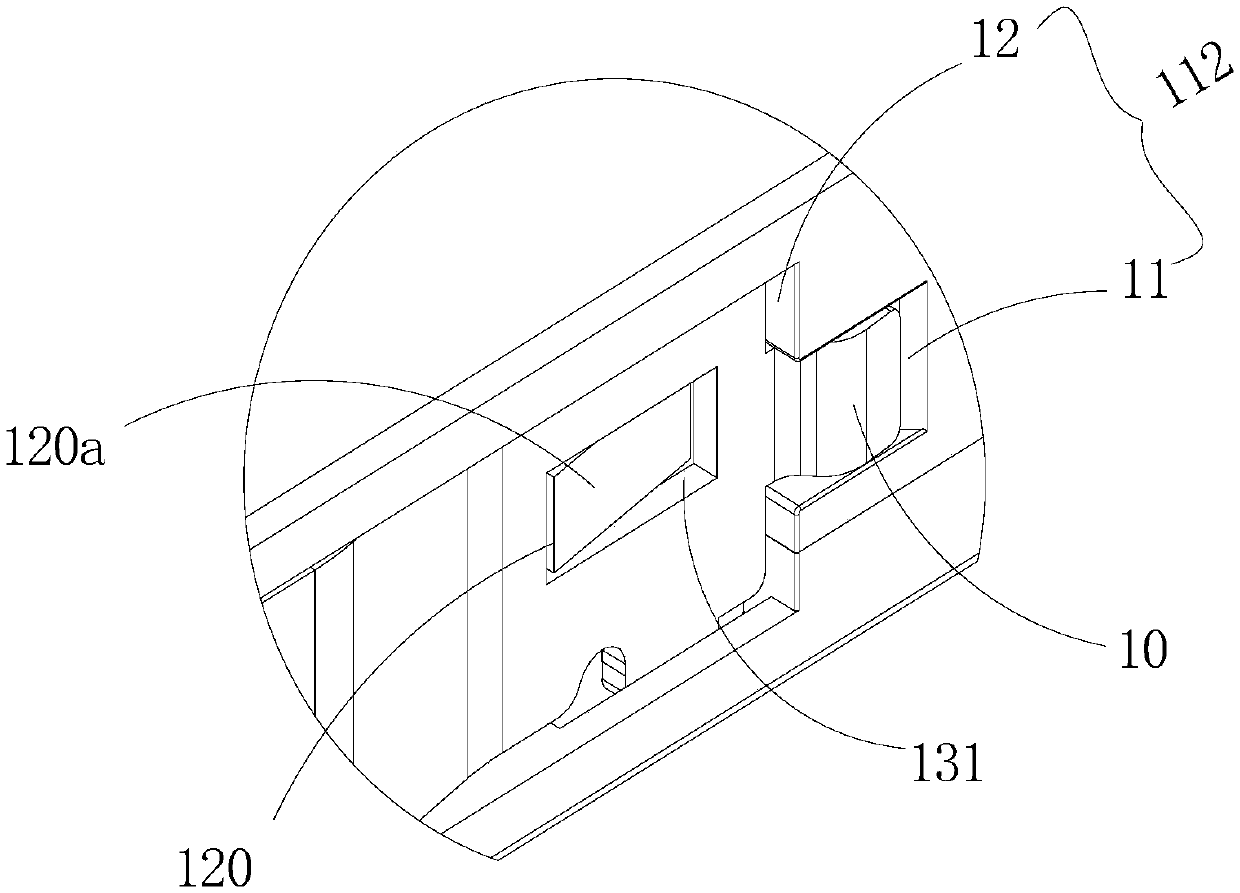

[0031] figure 2 yes figure 1 An enlarged schematic diagram of part N in the optical module shown. Two mounting slots are defined on both sides of the base 101 of the optical module 100 . figure 2 The two installation grooves on one side ...

Embodiment 2

[0035] This application also provides another embodiment, please refer to Figure 6-Figure 8 . The optical module 200 of this embodiment includes a base 201 , an upper cover 202 and a pull ring 203 . The pull ring 203 is installed on the base 201, and the base 201 and the upper cover 202 are fixed and installed by screws. The pull ring 203 is composed of a tongue 20, a ring arm 23 and a handle (not shown). Both sides of the pull ring are ring arms 23 , and the top end is integrally formed with the ring arm 23 and has a bent tongue piece 20 , whose width is smaller than that of the ring arm 23 . The tongue piece 20 and the ring arm 23 are integrally processed by metal material, and the handle can be made of soft rubber material.

[0036]There are two installation grooves on both sides of the base 101 respectively. The width of the first installation groove 21 is smaller than that of the second installation groove 22 . The difference from Embodiment 1 is that an escape groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com