Clamping type safety lock with clamping groove upper pins

A safety lock and tumbler technology, applied in the field of locks, can solve problems such as difficult mass production, complex manufacturing process, and difficult technology to unlock, and achieve the effects of easy mass production, simple manufacturing process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

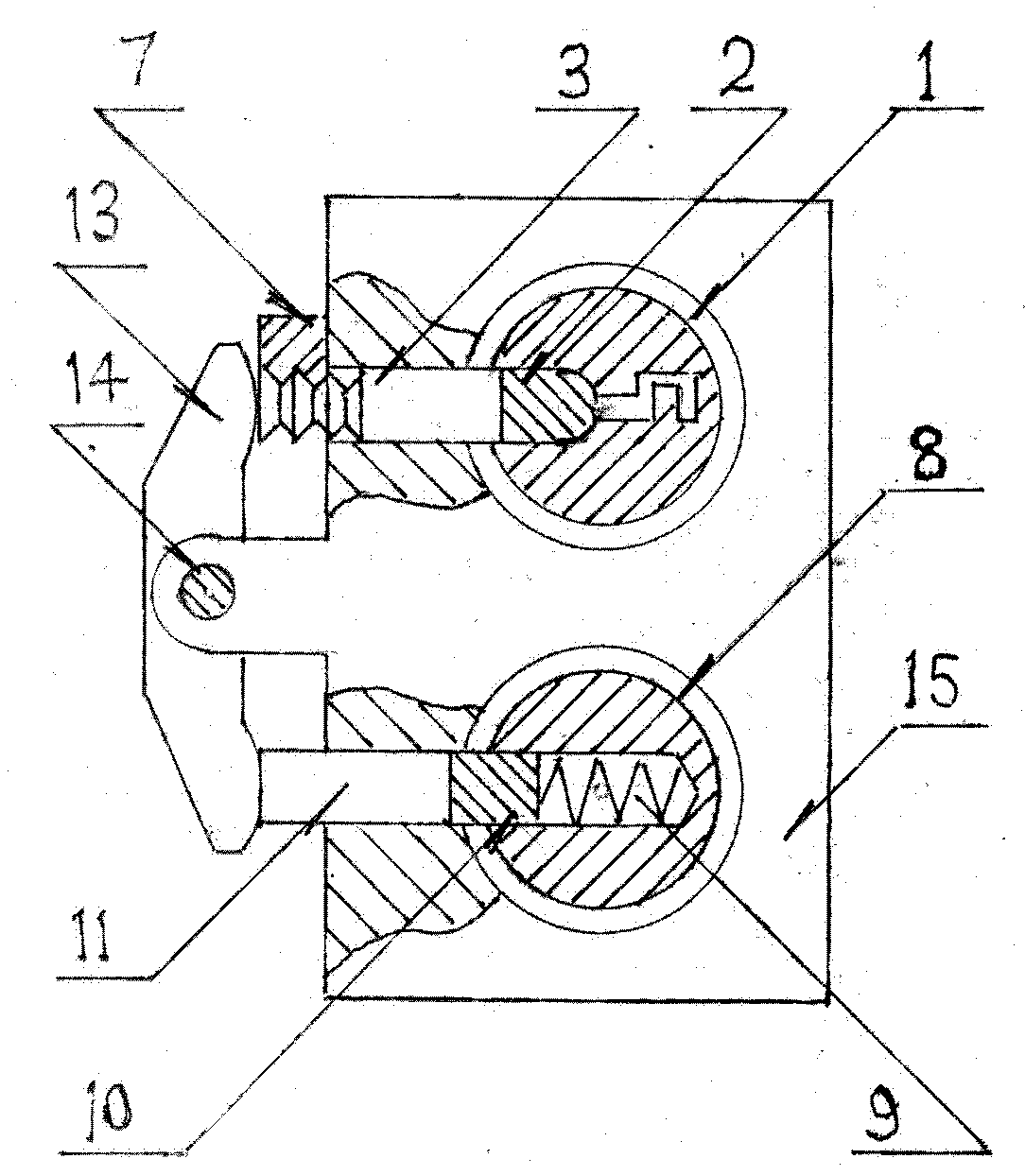

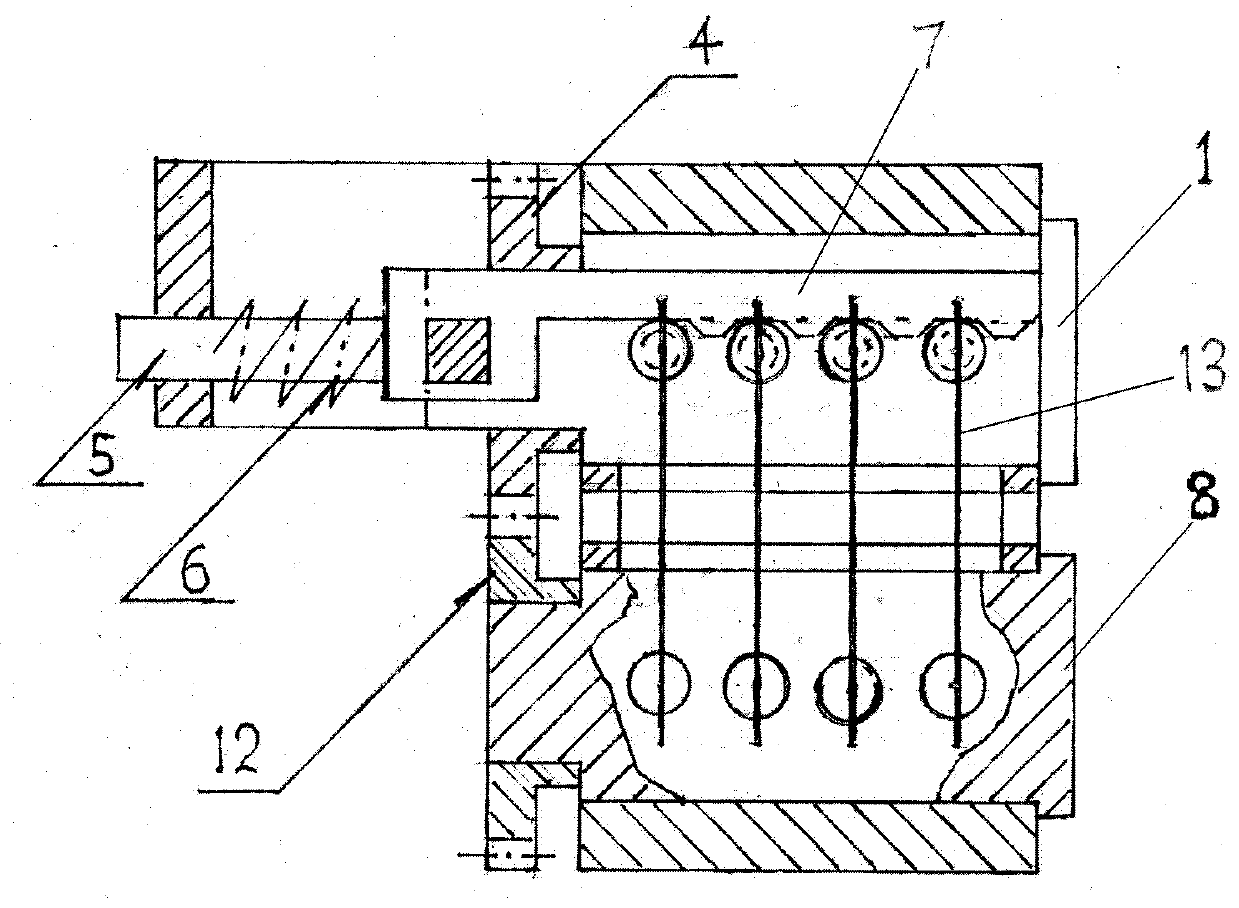

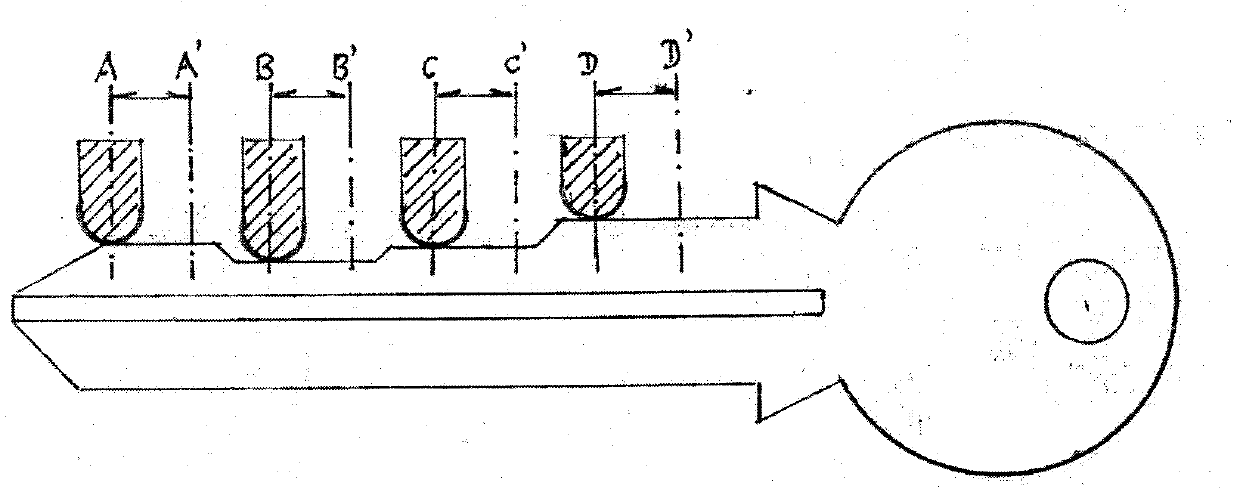

[0020] This embodiment provides a pin-type safety lock on a card slot, including: a self-locking system, a locking system and a self-locking compensation system. 2 and a lock body 15; the locking system is composed of pins 3 on the slot, a slot plate 7 and an L-shaped latch 5 with a compression spring 6 on the horizontal part, the pins 3 on the slot and the plate on the slot 7 are respectively movably installed on the lock body 15, the upper marble 3 of the card slot is in contact with the end surface of the lower marble 2 of the ball head, the vertical part of the card bolt 5 is connected with the described card slot plate 7, and the horizontal part of the card bolt 5 The end is clamped on the lock body 15, and the end of the main lock core 1 is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com