Power box

A technology for power boxes and box doors, applied to electrical components, substation/switch layout details, building fastening devices, etc., can solve problems such as unsafe use, detachment of lock levers, easy unlocking, etc., to improve the safety of use, Improve the effect of user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

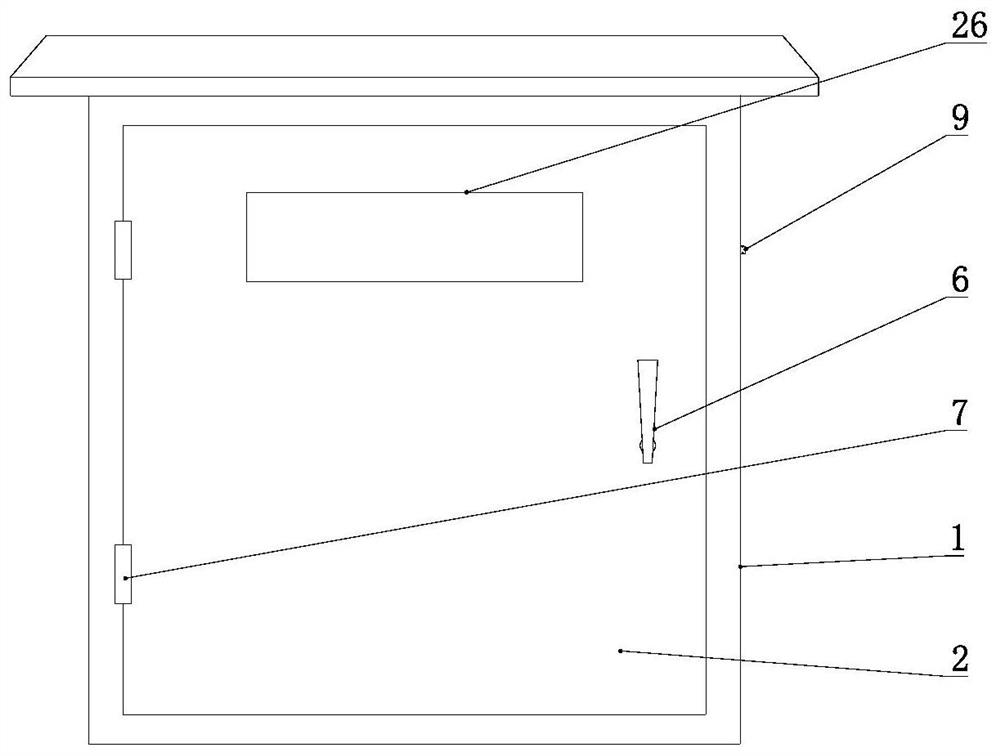

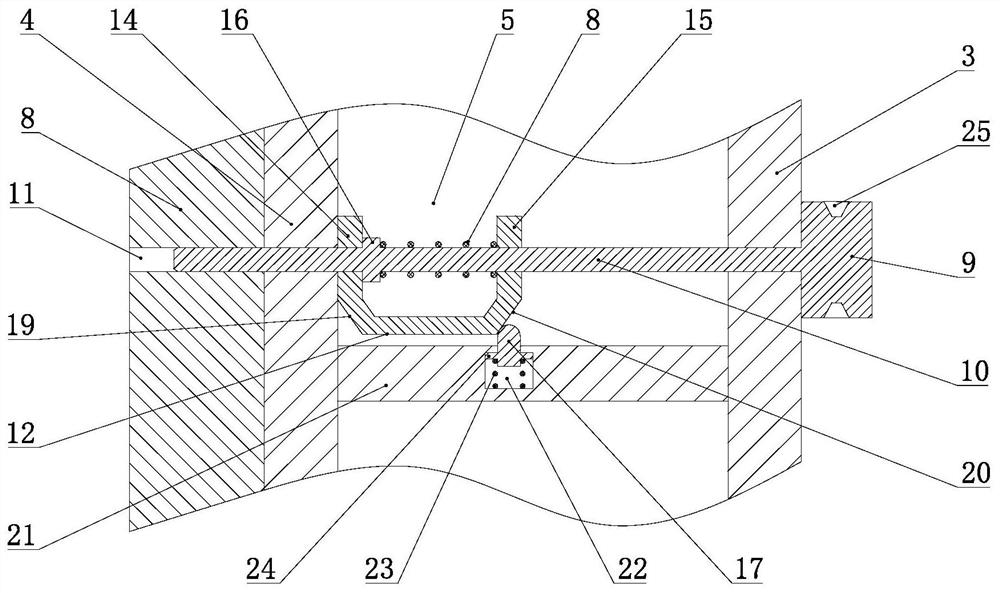

[0019] Example 1: Please refer to Figure 1-Figure 2 , the safe-to-use power box in the embodiment of the present invention includes a box body 1 and a box door 2, the box body 1 includes an outer box body 3 and an inner box body 4, the inner box body 4 is used for placing electrical components, etc., and the outer box body 3 An insulating cavity 5 is formed between the inner box 4 and the inner box 4, so that the inner box 4 is less affected by the temperature of the external links. The left side of the box body 4 is movably connected, and the right side of the box door 2 is provided with an inward connecting edge 8. The connecting edge 8 is formed by folding inward from the right side of the box door 2. After the box door 2 is installed in place, the connecting edge 8 is connected to the inner side. The right side of the box body 4 is in contact with the right side of the outer box body 3, and the right side of the outer box body 3 is provided with a lock button 9. It may be...

Embodiment 2

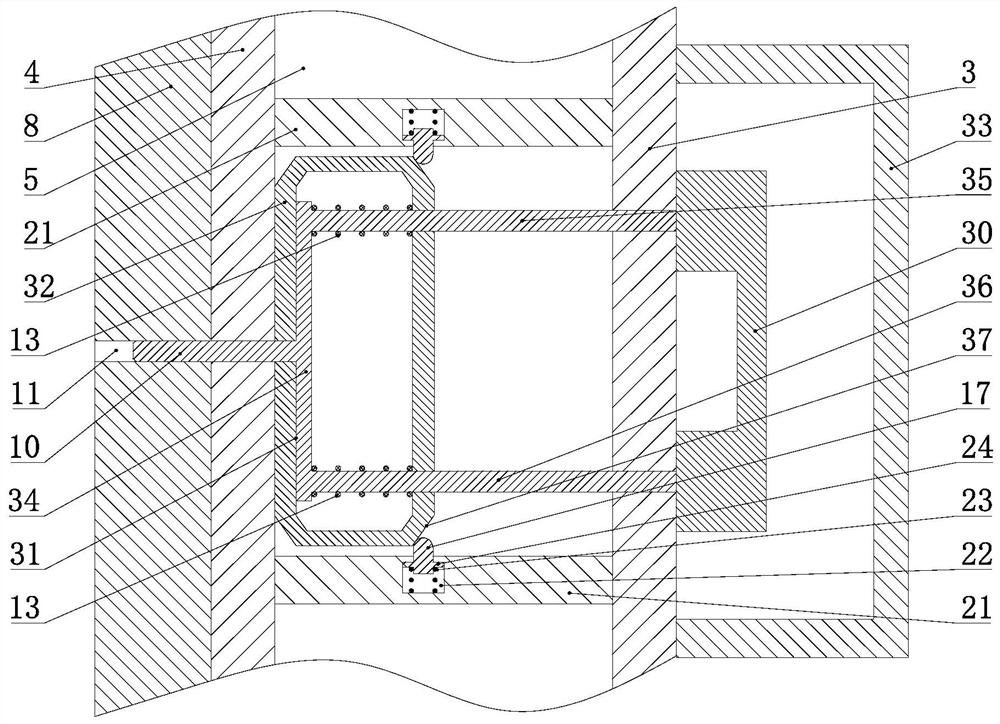

[0022] Embodiment 2: What is different from Embodiment 1 is that combined with image 3 In this embodiment, a lock handle 30 is provided on the right side of the outer box 3, and a lock frame 31 is connected to the left side of the lock handle 30. The lock frame 31 is slidably fitted with a positioning seat 32 and a resistance spring 13. The seat 32 and the resistance spring 13 are located in the heat insulating cavity 5 , the left side of the lock frame 31 is connected with the lock rod 10 , the lock frame 31 abuts the left side of the positioning seat 32 under the action of the resistance spring 13 and isolates the lock rod 10 from The hot cavity 5 and the inner box 4 extend into the locking hole 11 of the connecting edge 8 . In this embodiment, a lock frame 31 , a positioning seat 32 and a resistance spring 13 are added between the lock handle 30 and the lock rod 10 , so that when the lock handle 30 is pulled outward, the lock must be overcome after the resistance spring 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com