Gap adaptive vertical snapping roll device

A spike picking roller and self-adaptive technology, applied in the field of agricultural machinery, can solve the problems of header congestion, vertical header congestion, and stalk breaking, and achieve the effects of avoiding congestion, reducing impact, and avoiding loss of shedding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the present invention clearer, the invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments.

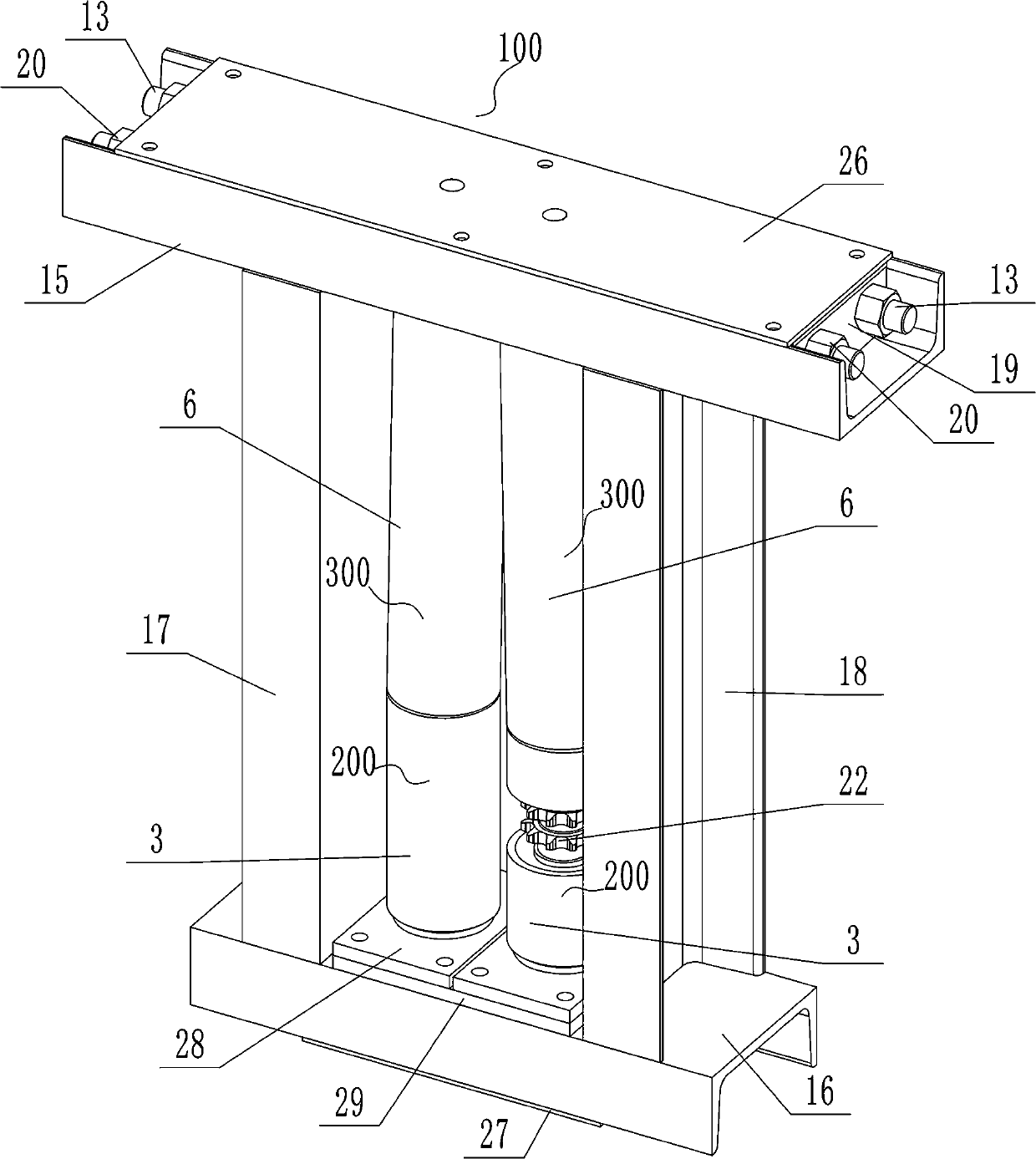

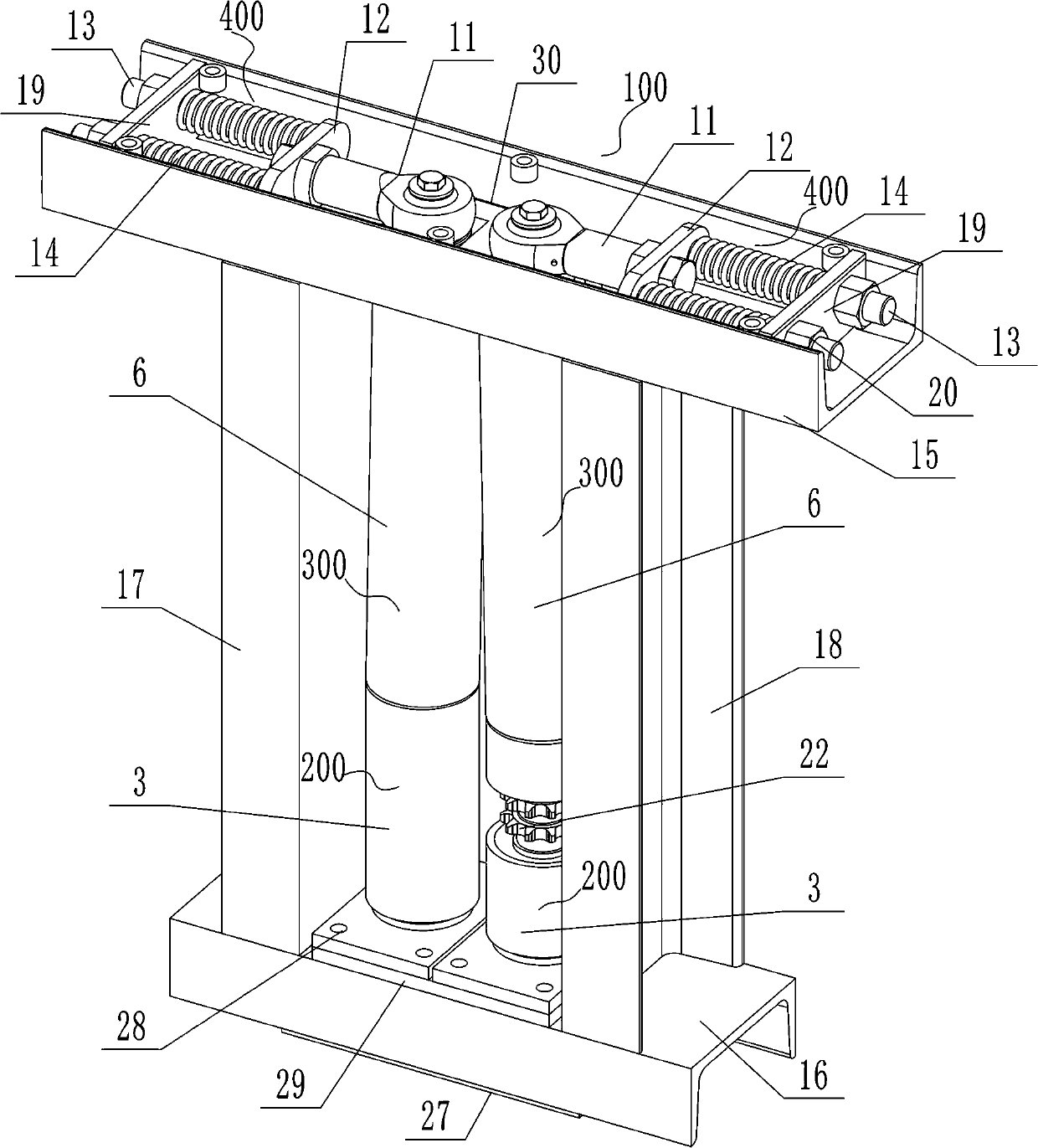

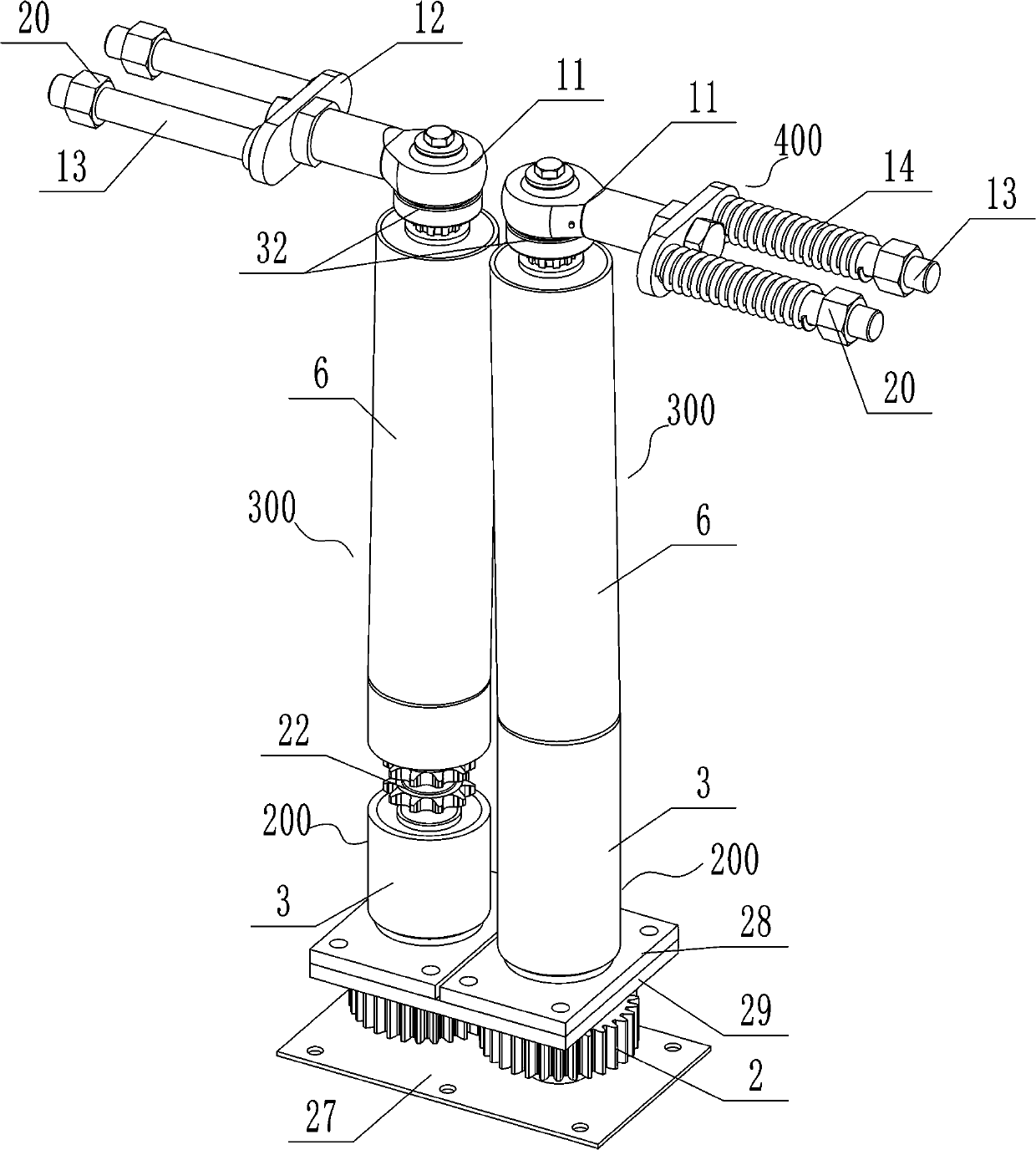

[0034] Such as Figure 1-9 A kind of gap self-adaptive vertical ear picking roller device shown, it comprises installation frame 100 and two groups of clamping devices that are arranged on described installation frame 100, described clamping device of two groups rotates oppositely, clamps corn stalk The corn stalks are transported obliquely upwards and backwards. Since the corn stalks are continuously transported backwards, the ears are squeezed out when they reach the two clamping devices.

[0035] Such as Figure 1-2 As shown, the installation frame 100 includes an upper beam 15 and a lower beam 16 arranged in parallel, a left bracket 17 and a right bracket 18 are arranged in parallel between the upper beam 15 and the lower beam 16, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com