Welding device with clamping structure for electric head

A welding device and clamping structure technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment and other directions, can solve the problems of the welding machine not working normally, the applicability and practicability limitations, and easy to cause electric shock accidents, etc., to achieve the connection Convenient and fast, good practicability, good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

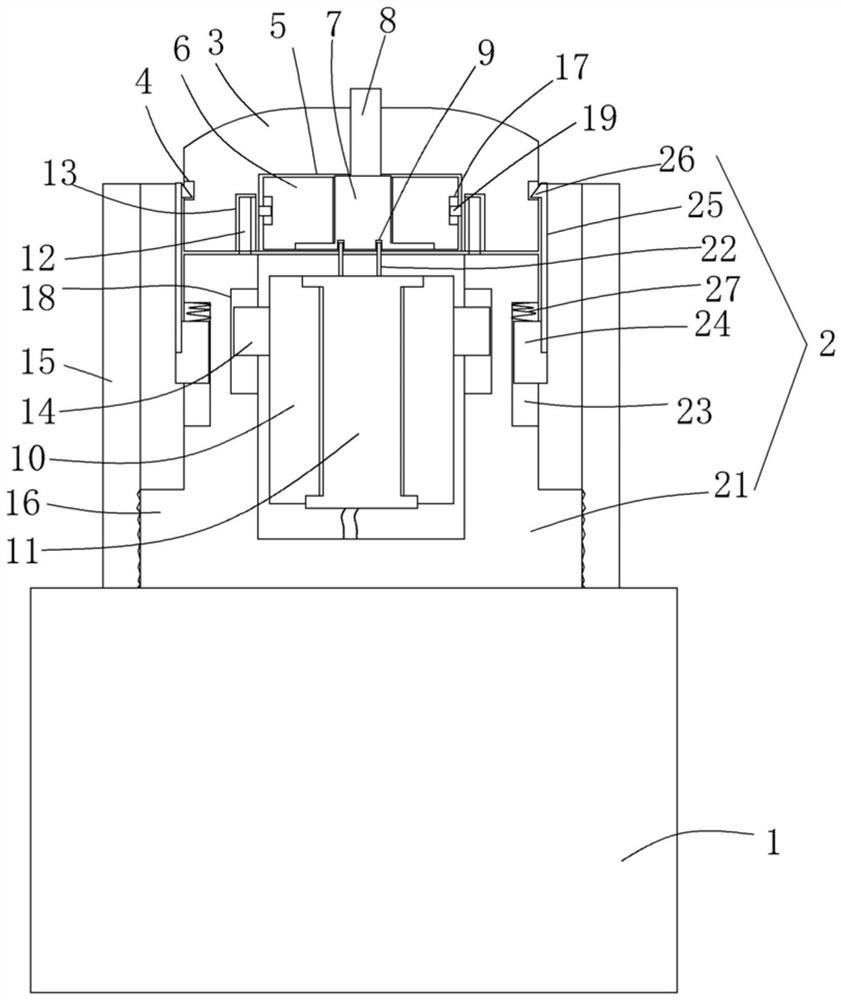

[0014] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0015] See figure 1 , a welding device with a connecting head clamping structure, comprising a welding device 1 (this is a conventional structure in the prior art) and a connecting head structure 2 fixed on the welding device, and the connecting head structure 2 includes a connecting head structure The electric seat 21 is provided with an electric connection socket 22 at the center of the electric connection seat, and three dovetail-shaped vertical chute 23 are evenly opened on the outer wall of the electric connection seat, and in the vertical chute A dovetail-shaped slider 24 is provided, and a locking plate 25 is fixed on the outer wall of the slider, and a buckle protrusion 26 is integrally formed on the top of the inner surface of the locking plate. A return spring 27 is fixed between the surface and the top wall of the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com